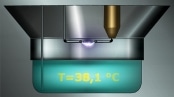

The MINIFLASH TOUCH is an exclusively designed flash point tester for determining flashpoints of solids and liquids, using the Grabner flash point detection technique of measuring the instantaneous pressure rise within the continuously closed chamber, activated by an energy-controlled electric arc. The condensation of high-volatile compounds is prevented by heating the test chamber from the top and thus optimizing the test results considerably.

Due to its small sample volume of only 1–2 mL and continuously closed cup design, offensive fumes in the testing area are prevented, maximum safety is provided, and sample waste is minimized. The rapid thermoelectric cooling after a test is over and the quick and effortless handling of the instrument save valuable labor time.

Features

The full-color touch-screen of the MINIFLASH TOUCH functions on Microsoft® Windows® software and features inherent menu navigation that does not need any training for flashpoint testing. Together with its convenient touch screen design, the MINIFLASH TOUCH provides trouble-free communication with USB, an expanded temperature range from 0 to 400 °C, LIMS, Ethernet, and PCs and almost unlimited storage capacity for programs and results.

MINIFLASH determines the flash point as per ASTM D6450 and the advanced ASTM D7094 standard. This method defines the “Standard Test Method for Flash Point by Modified Continuously Closed Cup (MCCCFP),” which provides the highest reproducibility and repeatability and an outstanding link to the D93 Pensky-Martens method: “there is no statistically significant bias observed between ASTM D7094 and ASTM D93 Procedure A” as concluded during the last Round Robin. The ASTM committee has approved the ASTM D7094 for the Diesel Fuel and Kerosene specifications ASTM D975, D396, D2880, and D3699.

Additionally, test results are comparable to other established standards such as Abel and TAG, and its exclusive design enables MINIFLASH to be used in more challenging applications, for example, flash-point testing of contaminated samples like diesel fuel in lube oil or gasoline in diesel fuel and for biodiesel testing. The new MINIFLASH TOUCH analyzer also incorporates enhanced techniques for simulation of EN ISO 3679 and EN ISO 3680.

Additionally, test results are comparable to other established standards such as Abel and TAG, and its exclusive design enables MINIFLASH to be used in more challenging applications, for example, flash-point testing of contaminated samples like diesel fuel in lube oil or gasoline in diesel fuel and for biodiesel testing. The new MINIFLASH TOUCH analyzer also incorporates enhanced techniques for simulation of EN ISO 3679 and EN ISO 3680.

In addition, the true portability and strong housing of the MINIFLASH TOUCH make it the ideal solution for mobile labs and military applications.

The New Technology

Peltier Protection Technology™

Grabner Instruments designed fast thermoelectric regulation of cooling and heating for rapid sample turnaround and prolonged instrument lifespan. This technology allows the measured temperature to be increased far beyond 400 °C and improves Peltier performance and lifetime.

Ignition Protection Technology™

Ignition Protection Technology™ is inherent to the MINIFLASH design. It just requires 1–2 mL of sample for testing the flash point without an open flame. With its continuously closed cup design, automatic explosion probing, and a controlled air feed, incomparable safety is offered in flashpoint testing by protecting from fire and offensive fumes.

Combustion Analysis™

At times, samples include small concentrations of flammable compounds, which do not display an exact flashpoint. With MINIFLASH TOUCH, even very small flames can be detected and the presence of contamination in those samples can be graphically visualized.

Flexibility

The potential to control parameters such as ignition energy, heat rate, and the amount of atmospheric oxygen present in the combustion chamber enables simulation of almost any flash point method and environmental condition.

Wide Application Range

Flashpoints are determined across a broad temperature range, simulating all standard closed cup methods and also GO/NOGO tests with just 1–2 mL of sample. The programmable fuel dilution curve (diesel fuel or natural gas in lubricating oil) is a valuable tool for used oil analysis to avoid expensive engine troubles. Over the last years, the exceptional performance of MINIFLASH has proven effective for transport regulations/classifications, used oil analysis, and product specifications globally.

Other Applications of MINIFLASH

Petrochemistry

Petrochemistry

Used in flash point testing of residuals, sludge, bitumen, and so on. The device enables quick screening of jet fuel and diesel fuel to check for the final presence of low flash contaminants. Advantage: very safe operating procedure and high temperature range.

Pharmacy

Used in flash point testing of products comprising solvents such as ethanol, IPA, glycerol, and others. Advantage: small sample volume.

Transport

Used in flash point testing of flammable goods to confirm whether it meets transport safety regulations. Advantage: easy to handle.

Flavors and Fragrances

Use in flash point testing of aroma products comprising alcohol-based solvents. Advantage: small sample volume considerably minimizes testing costs in case of expensive base products.

Paints and Varnishes

Used in flash point testing of solvent-based varnishes, enamels, and paints to determine the safest storage means. Advantage: easy cleaning and small sample volume.

Waste Disposal

Used for testing industrial waste such as solids (filter slurry) and unknown mixtures of liquid hydrocarbons. Advantage: small sample volume and quick thermoelectric cooling in the case of samples that have a flash point well below ambient temperature.

Maintenance of Pumps, Engines, etc.

Fuel dilution in lube oils alters its viscosity, which in turn changes the lubricating properties of the oil, leading to increased wear of mechanical parts because of higher friction. This can ultimately result in severe damage and engine drop-out. Fuel dilution reduces the flash point.

MINIFLASH Touch Operation Workshop