The Ceramscan available from Stable Micro Systems is a benchtop laser-based scanner that quantifies the density, volume and dimensional profiles of ceramic pieces.

Laser profiling has been pioneered as a non-contact, non-destructive method of measuring density, which is particularly suited to fragile samples, such as green compact ceramics.

Given the potential inaccuracies of displacement methods in determining porosity in ceramics and the toxicity issues with the use of mercury, manufacturers have been keen to explore other options.

When compared to contact and displacement methods that measure only volume, this non-contact measurement system provides substantial benefits beyond removing many of the inaccuracies and limitations of traditional density measurement techniques.

How a Ceramscan Instrument Works

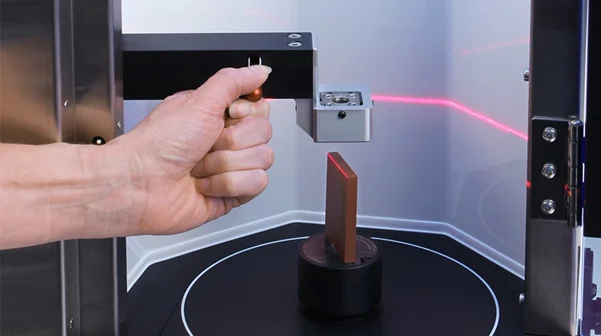

Stable Micro Systems’ Ceramscan instrument works by loading a sample onto a disposable plate to which the sample can be adhered to support it on its perimeter. The desired settings can be simply entered into the software before running the test.

Measurements are automatically produced after each scan, including volume, surface area and density. It is also easier to compare samples of the same batch, as the mean, standard deviation and coefficient of variation are automatically calculated.

During the test, the product is weighed on an external balance – measuring to three decimal places. The laser device, which has been declared safe for eyes, is scanned vertically to measure the contours of the product at selectable intervals while it rotates.

Each interval collects 400 data points to provide a detailed profile. Density scans can be performed quickly using this method, ranging from a few seconds to several minutes depending on the chosen interval (0.05 mm to 50 mm) and the preferred degree of precision.

Manufacturers can test samples up to 300 mm in height and 190 mm in diameter, with a weight of up to 3 kg (using the loadcell within the instrument), making it also suitable for tiles and tableware, among others.

Image Credit: Stable Micro Systems Ltd

Why Measure Volume, Density and Product Dimensions Using a Ceramscan?

- Fluid displacement techniques are not suitable for porous materials. The Ceramscan is a non-contact laser-based measurement that is not affected by sample porosity.

- Mercury displacement techniques represent a toxic risk to the environment and are therefore illegal in many countries. The Ceramscan has been verified as accurate as mercury displacement methods.

- Gas displacement techniques usually measure very small samples or otherwise attract a high instrument price. The Ceramscan has the largest measurement envelope in its class.

- X-ray techniques are expensive and present a health and safety issue and therefore require fully trained operators. The Ceramscan uses an eye-safe laser and therefore is the safest procedure for density determination.

- Verifiable Measurement - A measurement is valuable only if it is accurate. This is why users will want to have control of instrument calibration and the means to confirm that the instrument performs accurate measurement by testing a 'Known Volume Verification' ball.

- Digital data - The Ceramscan allows fast 3D digitization of products that can be stored and then mathematically treated to produce comprehensive dimensional information for instant use or future retrieval. When users can automatically calculate various associated parameters, like surface area, specific volume, density, length, width, height, weight and many more, why restrict to just volume measurement?

The Future of Density Measurement and Beyond

Ceramics and other laminate structures need to display minimal porosity in order to maintain their structural integrity and ensure high quality end products. However, the fragile nature of the material means that it is particularly difficult to measure.

While traditional methods of measuring density, such as gas pycnometry, are adequate in gaining a reasonable view of the sample, they are also dependent on stable conditions to make optimum calculations.

Having access to a method of measuring density that avoids damaging fragile ceramics is a lower cost and less time-consuming alternative to more traditional techniques. In addition, laser profiling instruments, such as Stable Micro Systems’ Ceramscan, offer promising replacements for traditional toxic methods, allowing manufacturers to make accurate judgements by the safest means possible to inform the formulation process and enhance the quality of their end products.

Density measurements of ceramics and advanced materials is amongst many other tests that can be performed on Stable Micro Systems’ physical testing instruments.

Image Credit: Stable Micro Systems Ltd

Technical Specification: https://www.stablemicrosystems.com/CeramscanSpecification.html

Request a Demonstration: https://www.stablemicrosystems.com/DemonstrationRequest.html

Request a Brochure: https://www.stablemicrosystems.com/BrochureRequest.html