Applied Test Systems unveiled an innovative solution for Creep and Stress Rupture testing known as the SIGMA Testing System.

SIGMA represents a groundbreaking advancement for WinCCS, the trusted control software, and the first and second-generation controllers that have been the backbone of major testing facilities worldwide for over three decades.

The SIGMA system keeps WinCCS as the control software while introducing the cutting-edge third-generation SIGMA controller and state-of-the-art SIGMA testing machines.

As a result, the SIGMA system is fully backward compatible with prior controllers and data to protect your existing WinCCS systems.

Sigma Machines Series 2320 & Series 2610. Image Credit: Applied Testing Systems

Sigma Testing System Overview

The SIGMA Testing System is an automated solution employed for conducting tests, including Creep and Stress Rupture analysis.

This testing system consists of three essential components: the WinCCS SIGMA control software, the SIGMA test controller, and a variety of testing machines tailored to meet the specific needs of end users.

WinCCS SIGMA

The existing WinCCS is a Windows PC-based application that operates on a computer located within the user's laboratory. The computer is directly connected to the laboratory's test machines through communication cables. Within the control software, a comprehensive library of testing methods for creep/stress rupture testing, as well as calibration and verification records, and specimen data collected during tests, is meticulously maintained.

WinCCS excels at generating reports and graphs, facilitating the presentation of test data in a variety of user-friendly formats. It enables comprehensive testing in accordance with the specifications of ASTM, ISO, and turbine engine manufacturers.

WinCCS SIGMA represents an upgraded version of WinCCS, featuring a redesigned interface that enhances the operator's user experience. WinCCS SIGMA introduces a new reporting feature that empowers users to generate reports in the form of HTML documents.

Moreover, WinCCS SIGMA offers the option of integrating with a Laboratory Information Management System (LIMS) interface, enabling seamless communication of specimen test parameters and data with existing LIMS systems. Importantly, WinCCS SIGMA maintains compatibility with all previous versions.

SIGMA Controller

The SIGMA Controller is a microprocessor-based device responsible for managing various aspects of SIGMA Test Machines, including specimen temperature, stress/strain control, as well as data measurement and collection.

Once initiated by the WinCCS SIGMA control software, the SIGMA Controllers operate autonomously, overseeing the entire test process without requiring further input from the host PC.

As the third-generation iteration, the SIGMA Controller incorporates the latest hardware advancements, delivering exceptionally precise control.

This version represents a significant technological leap over its predecessors, offering improved processing speed, data acquisition rates, and control loop response times. Notably, the SIGMA Controller introduces a redesigned load control system that employs stepper motor technology to control the axial specimen load, thereby enhancing precision in load control to a new level.

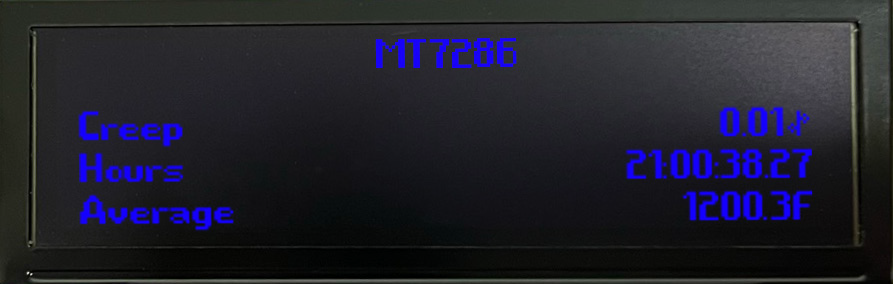

In addition to the SIGMA Controller, an enhanced SIGMA user terminal has been introduced, boasting a range of new features.

These features encompass an OLED display with excellent visibility and machine jog up/down buttons, simplifying the setup process. Importantly, the SIGMA terminal maintains compatibility with all previous test machine controllers.

SIGMA Machines

SIGMA Machines exert an axial load on a specimen while maintaining an elevated temperature. Throughout the test, SIGMA diligently records and monitors the parameters of the machine and specimen.

These machines employ a specimen furnace and offer the flexibility of generating the axial specimen load through either manually loaded fixed weights or automated load control methods.

The operation of a SIGMA Machine is overseen by a microcomputer-based test controller. This controller receives all the necessary test parameters from WinCCS SIGMA and subsequently conducts the test on the specimen.

An exciting addition to the SIGMA lineup is the direct loading model 2610 Test Machine, boasting a 10,000 lbs capacity while conserving laboratory space. The 2610 Test Machine is fully automated and eliminates the need for weights.

Status Display Screen. Image Credit: Applied Testing Systems

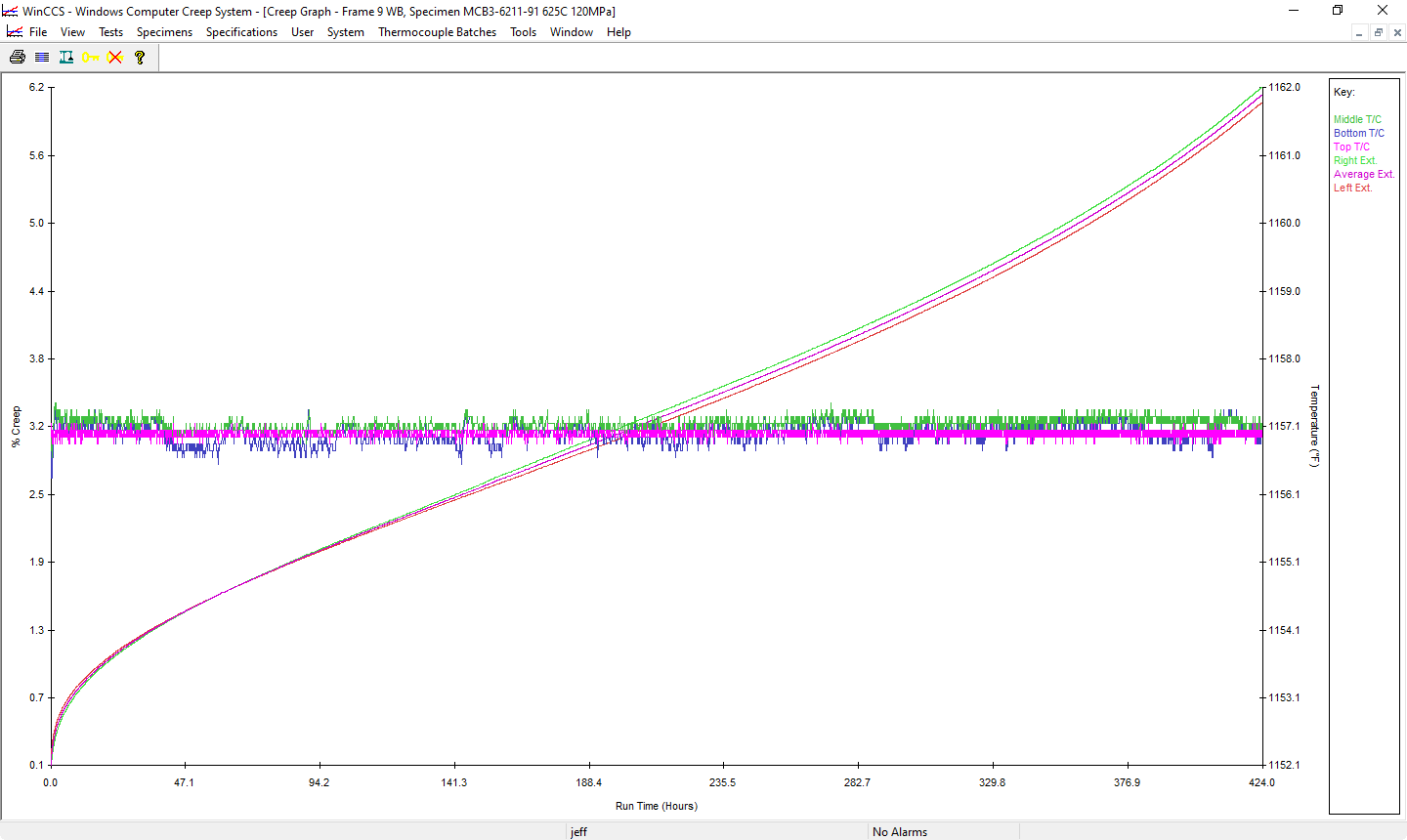

Creep Graph with Specimen Temperature. (*actual test data). Image Credit: Applied Testing Systems

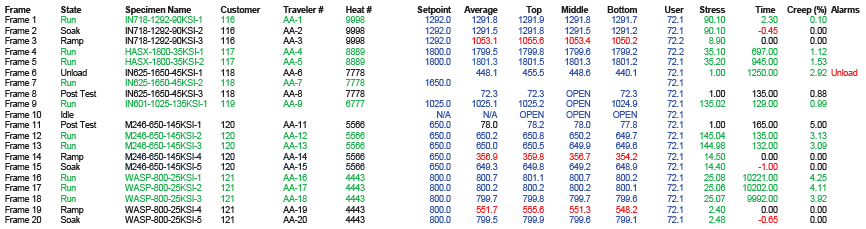

Testers available with the Sigma Testing System. Source: Applied Testing Systems

| |

2140-W3 |

2320-W3 |

2330-W3 |

2410-W3 |

2510-W3 |

2610-W3 |

| Max Force (Pounds) |

600 lb. |

10,000 lb. |

12,000 lb. |

20,000 lb. |

50,000 lb. |

10,000 lb. |

| Max Force (KN) |

2.67 KN |

44.5 KN |

53.4 KN |

89 KN |

222.4 KN |

44.5 KN |

Optional Enhancements

Digital Displacement Option

This feature allows for the integration of one or two Heidenhain displacement gauges into the system, specifically for creep and/or stress relaxation testing. It encompasses the necessary cabling, connectors, and software to seamlessly incorporate the displacement gauges into the user Test Machine.

Analog Displacement Option

This feature empowers users to link one or two LVDTs or analog displacement measuring devices (for example, laser extensometers) to the system, primarily for creep testing. It includes the essential cabling, connectors, and software required to seamlessly integrate these displacement gauges into user Test Machine.

Automatic Hot Step Load Option

This feature harnesses dedicated software and hardware to enable the SIGMA Test System to autonomously perform hot step loading for creep tests, eliminating the need for operator intervention.

It encompasses a Load Cell with electronic signal conditioning and adapters, a specialized weight pan, and an additional lever arm counterweight designed to counterbalance the load cell’s weight.

The operator’s responsibility includes loading the final test weights onto the machine before initiating the test. The maximum load capacity for this option is determined by the lesser of two factors—(i) the rated frame/lever arm capacity or (ii) the load cell’s capacity multiplied by the lever arm ratio.

Load Control Option (Standard on SIGMA 2610 Test Machines)

This feature allows the SIGMA Test Machine to be controlled by a weight-free specimen load without operator intervention. This option is particularly well-suited for laboratories conducting tests involving frequent load increments or short-duration creep tests with automatic step loading.

The package includes a Load Cell, Load Cell Adapters, a specialized weight pan, frame attachment hardware, and an additional lever arm counterweight to offset the load cell's weight.

The maximum load capacity for this option is determined by the lesser of two factors—(i) the rated frame/lever arm capacity or (ii) the load cell’s capacity multiplied by the lever arm ratio.

Stress Relaxation Package

This option offers the ability to conduct Constant Strain Testing, Constant Stress Testing, and Stress Relaxation Testing in accordance with ASTM E-328.

Cyclic Option

This option allows the Test Machine to cycle between preset specimen stresses with operator-specified dwell durations. During the increase and decrease load phases, the system collects data at a faster rate.

WinCCS SIGMA Portable Display Module Option

This feature allows users to manually control the draw head or elevator in addition to displaying the specimen test settings. This option can be used on numerous SIGMA Test Machines or earlier WinCCS generations, and it is backward compatible with all previous WinCCS versions.

WinCCS Portable Display Module. Image Credit: Applied Testing Systems

WinCCS Portable Display Module Main Screen. Image Credit: Applied Testing Systems

Option Recommendations per Test Type

Source: Applied Testing Systems

| Test Type |

Basic Tester with no options |

Load Control Option1 |

Automatic Hot Step Load Option2 |

Digital Displacement Option3 |

Analog Displacement Option3 |

Stress Relaxation Option |

Cyclic Load Option |

WinCCS Portable Display Module Option |

| Hydrogen Embrittlement F519 |

S |

O |

|

|

|

|

|

O |

| Stress Rupture |

S |

O |

|

|

|

|

|

O |

| Stress Rupture with Uploads |

S |

O |

|

|

|

|

|

O |

| Stress Rupture Combo |

S |

O |

|

|

|

|

|

O |

| Creep |

|

O |

|

R |

R |

|

|

R |

| Creep with Hot Step Loading |

|

O |

O |

R |

R |

|

|

R |

| Stress Relaxation |

|

R |

|

R |

|

R |

|

R |

| E328 Stress Relaxation |

|

R |

|

R |

|

R |

|

R |

| Constant Stress |

|

R |

|

R |

|

R |

|

R |

| Cyclic Loading |

|

R |

|

O |

O |

|

R |

O |

S: Standard

O: Optional

R: Required

1. Load Control is standard on Series 2610. System does not utilize weights

2. Requires Calibrated Weights

3. Select Digital or Analog