Epsilon’s Model 7650 extensometers simultaneously measure torsional and axial strains at high temperatures on specimens that are tested in torsional/axial machines. This model can be used with materials testing furnaces or induction heating up to 1600°C (2900°F). It can be used for bi-axial strain controlled fatigue. The slide mounting system enables mounting to hot specimens in seconds.

Epsilon extensometers are compatible with almost every brand of test equipment and can be supplied with the right connector so that it can be plugged in directly.

Operation of these, and all of Epsilon’s extensometers, are verified to applicable standards such as ISO 9513 or ASTM E83 using in-house calibration systems. These systems are calibrated with Epsilon’s laser interferometer system.

Epsilon has a 20+ year history of service for the materials testing community and will be there to stand behind their products when the user’s critical application requires it.

The model 7650 extensometers are primarily used on round specimens tested in bi-axial test machines that are capable of simultaneous axial and torsional loading. All of the models are capable of bi-directional displacement in both axes and can be used for strain-controlled fatigue testing under completely reversed load and strain conditions at frequencies ranging up to 10 Hz.

The 7650 extensometer models mount rigidly on the load frame and incorporate slide mounting to move the extensometer into contact with the specimen. The gauge length is set automatically before the extensometer is mounted on the test specimen, which enables hot mounting after thermal equilibrium has been realized.

These extensometers are specifically designed to reduce crosstalk between axes and to provide high resolution, high accuracy measurements. They incorporate capacitive sensors for low operating force. It also includes electronics with multi-point linearization and programmable filtering for enhanced performance and accuracy. The overall design reduces, and in many cases almost eliminates, any influence from common lab environment vibrations.

The model 7650 extensometers are water-cooled and are equipped with high purity alumina rods with conical rod tips for specimen contact when testing to 1200 °C (2200 °F). Silicon carbide rods are used for the 1600 °C (2900 °F) high temperature option.

These extensometers are often tailored for specific test needs. Epsilon can be contacted for a specific configuration to match the user’s equipment.

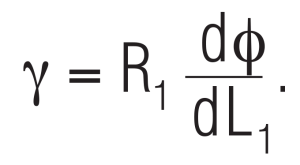

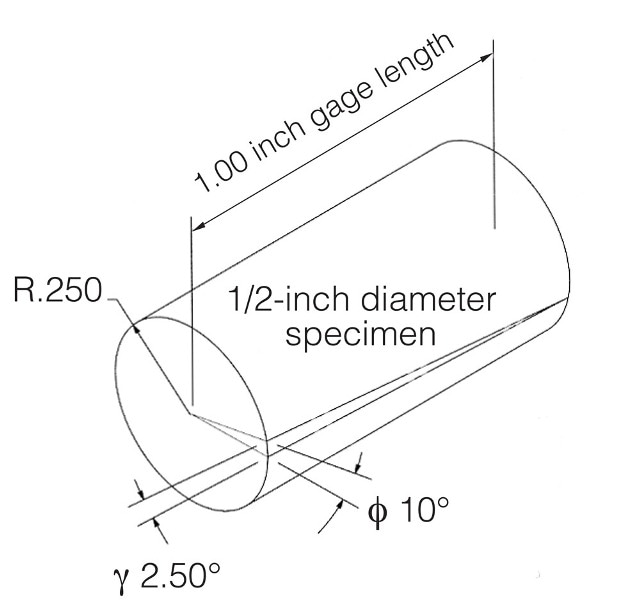

The Epsilon axial/torsional extensometer was engineered to directly measure the shear strain, γ, as illustrated in the figure. This design allows the correct determination of the shear strain without needing to know the radius of the specimen being tested, R1. The shear strain is related to the angle of twist (a frequently referenced parameter in torsion testing), φ, by the following relationship:

For extensometers that measure φ directly rather than γ, corrections have to be made for every different specimen diameter tested and for axial strain to determine the shear strain correctly.

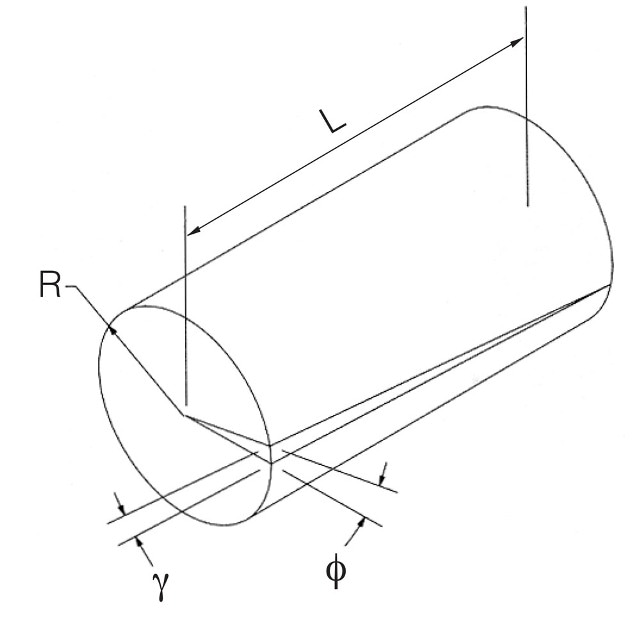

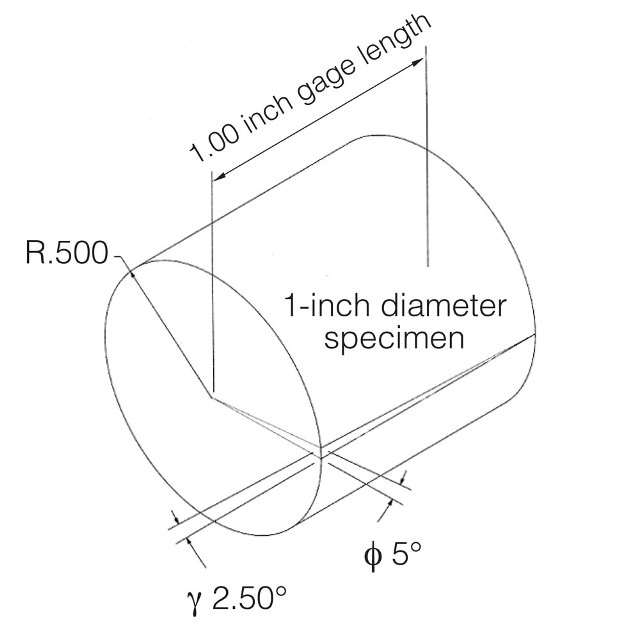

The following two examples illustrate the variation of the angle of twist versus a change in specimen diameter relative to the constant resulting shear strain:

Features

The key features of the Model 7650 extensometers are as follows:

- Self-setting gauge length with fine adjustment feature

- Hot mountable and retractable

- Standard units meet ASTM class B-1 requirements for accuracy (axial). Includes a test certificate. ISO 9513 class 0,5 test certificates are available upon request

- Delivers fully calibrated with calibration that is traceable to NPL; voltage output can be user-specified (typically 0 - 10 V)

- All models can measure in both tension and compression and can be used for cyclic testing at test frequencies up to 10 Hz

- Superior ambient vibration rejection; primary vibration mode >100 Hz typical

- Includes high speed analog and digital outputs

- Includes power supply and digital controller. Provides high level DC voltage output with low noise. Easily interfaced to data acquisition boards, test controllers, and chart recorders

- Multiple extensometer calibration files can be loaded for use with one controller

- Built-in calibration reference and auto-zero features

- Web-based user interface for setup and data acquisition

- Selectable analog and digital filter options from 2 Hz to 3 kHz

Specifications

The key specifications of the Model 7650 extensometers are as follows:

- Cyclic testing: Up to 10 Hz, depending on test system and test amplitude

- Linearity: 11 point digital linearization, ≤0.1% FS typical linearity (axial and torsional)

- Hysteresis: ≤0.1% FS typical

- Filter: Selectable 100 Hz analog and 2 Hz – 3 kHz digital filters

- Analog output: User specified, ±10 VDC typical, ±10.8 VDC rail

- Digital output: 24 bit high speed Ethernet output with built-in web interface

- Resolution: <75 PPM (0.0075%FS) RMS @ 4 kHz, <6 PPM (0.0006%FS) @ 100 Hz at gauge length

- Sensor cables: 2 m (6.5 ft) room temperature cables

- Output cables: Flexible 2.4 m (8 ft) analog output cables

- Power: Includes power supply for the user’s country

- Operating force: <30 grams typical

- Specimen size range: Fits most round specimen diameters

- Crosstalk: ≤0.2% FS typical at ±1° shear with 25 mm diameter specimen and 12.5 mm gauge length

- Environment: Recommended for testing in vacuum, dry air, or inert/non-corrosive gases

- Test frame layout: Accommodates test frames with torsional actuator located above or below specimen

- Contact force: <560 grams typical

Options

The following are the options available with the Model 7650 extensometers:

- High temperature option (-HT suffix) for use to 1600 °C

- Load frame mounting brackets

- Bulkhead adapters for use in vacuum chambers

- Model 2050 constant temperature water re-circulating bath

- Connectors to interface to nearly any brand test equipment

Measuring Axial and Torsional Strains at Temperatures up to (1200°C or 1600°C) with the 7650 High Temperature Axial/ Torsional Extensometers

Extensometer_for_high_temperature_biaxial_axial_torsional_strain_measurement-Model_7650-cu

Elevated_temperature_axial_torsional_extensometer_for_use_with_furnaces-Model_7650-uc

Extensometer_for_elevated_axial_torsional_strain_measurement-Model_7650_with_signal_conditioner

High_temperature_biaxial_strain_measurement_extensometer-Model_7650

Constant_temperature_water_cooling_recirculator-Model_2050-5