May 23 2016

Since the beginning of Bronze Age, 7,000 years ago, the development of novel metallic alloys was mostly a trial-and-error method. Usually, a single metal component was always believed to be the dominant factor, with other constituents merely making up a part of the recipe.

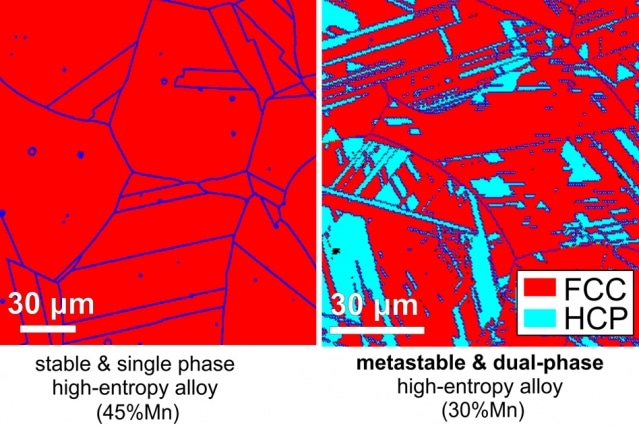

These images show the crystal configurations, or phases, within samples of metal alloys: a single-phase stable alloy (left) and a dual-phase alloy (right), which is metastable (has more than one stable configuration). The dual-phase material turns out to have better strength and ductility than the singe-phase material, the researchers found. Courtesy of the researchers

These images show the crystal configurations, or phases, within samples of metal alloys: a single-phase stable alloy (left) and a dual-phase alloy (right), which is metastable (has more than one stable configuration). The dual-phase material turns out to have better strength and ductility than the singe-phase material, the researchers found. Courtesy of the researchers

Now, a new study proposes a unique approach that could reverse this ancient and widespread metallurgical assumption and could pave the way for novel types of alloys with combinations of properties that were never seen before.

The results of the new strategy have been reported in the Nature journal, by C. Cem Tasan, the Thomas B. King Career Development Professor of Metallurgy in MIT’s Department of Materials Science and Engineering, and four other researchers at the Max Planck Institute in Dusseldorf, Germany.

According to Tasan, the innovative method also confronts the age-old wisdom that enhancing the strength of metal alloys constantly leads to loss of ductility. Ductility is an important property that enables a metal to deform without actually breaking, for instance when a metal is compressed to form a car’s body panels.

We have lots of experience from hundreds of years, through trial and error, and we know very well that when you start mixing metals in roughly equal amounts, you do not have good mechanical properties in most cases, due to the presence of brittle intermetallic phases.

C. Cem Tasan, Professor of Metallurgy, MIT

However, a group of metal mixtures called high-entropy alloys (HEAs) has attracted a great deal of attention over the last few years. Many metallic elements are present in these metal mixtures in equal proportions, which according to materials scientists can produce single-phase microstructures with better mechanical stability and strength.

Tasan said that while this field has attracted a significant amount of interest, with over 300 papers published on HEAs last year alone, most of the compounds analyzed so far have not yielded any considerable enhancements in terms of their properties, and have continued to suffer the ductility-strength-tradeoff. He added that the key focus of the earlier analysis was only dedicated to studying the projected single-phase stabilization notion in diverse alloy systems. However, aiming for single-phase stable microstructures varies from the approach taken with steel - the most extensively used metal, of which 1,500 million tons are manufactured across the globe per year.

Steel has become a ubiquitous commodity because its numerous alloys can be modified to accommodate a variety of properties based on the particular application. Often, advanced steels possess stable phases, but also contain certain metastable phases (having more than a single stable configuration). Metastable phases, under stress, can change to stable configurations, thus enhancing their ability to resist breakage.

Unit now, the results reported for HEA materials have not proved their worth, “there are definitely interesting benefits of following this idea [of combining roughly equal portions of metallic elements],” such as realizing a property known as increased solid-solution hardening, Tasan says.

So we thought, why not combine the strength of this concept with the strengths of steels, the most important structural material for humanity?

C. Cem Tasan, Professor of Metallurgy, MIT

According to the latest results reported by Tasan and his research team, in HEAs it is not the typically sought-after stability, but rather metastability that yields the most promising alloys. With these principles in mind, an innovative alloy was designed, was made of cobalt, iron, chromium, and manganese. This alloy “outperforms even the highest-performance, single-phase, high-entropy alloy,” Tasan says. And, it provides excellent high values in terms of both ductility and strength.

“It’s like combining the best of two worlds: metastability, known from steels, and the solid-solution strengthening of HEAs,” he says. Tasan, however, added that apart from the characteristics of this specific alloy, what is more important is the underlying approach used for manufacturing it, which could eventually provide new opportunities for designing alloys with new properties.

We think this is just one example of the kind of alloys that could be produced. [Hopefully] one could produce even better ones, since the new strategy is a generic tool for the design of new materials. I think this result will be very influential in guiding the HEA research community to achieve superior property combinations.

C. Cem Tasan, Professor of Metallurgy, MIT

Dubbing this work “unique and creative,” Ke Lu, professor and director of the Shenyang National Laboratory for Materials Science in China, who was not part of the study, says: “The authors utilized different strengthening mechanisms into an alloy system in a very smart way, leading to a simultaneous increase of strength and ductility that are often exclusive. While each individual mechanism is well documented in many different systems, a synergic application of these effects is novel and original. The properties achieved are impressive indeed.” These findings could “open up new dimensions of materials innovation and development,” he adds.

Other researchers who took part in the study are Konda Pradeep, Zhiming Li, Dierk Raabe, and Yun Deng at the Max-Planck Institute for Iron Research in Dusseldorf, Germany.

The European Research Council supported the study.