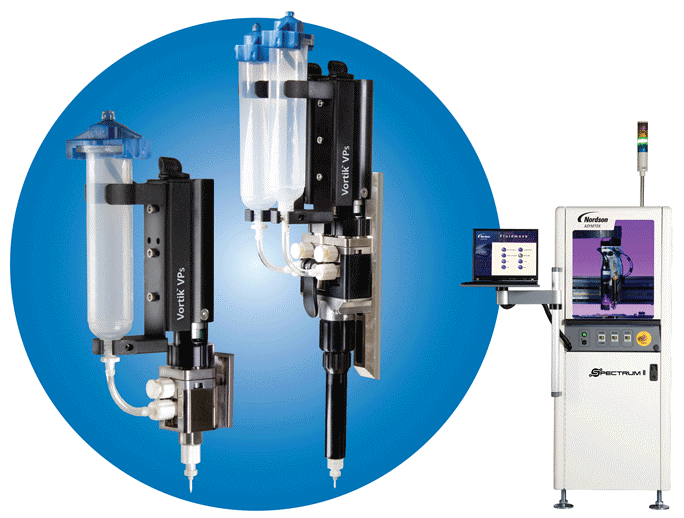

Nordson ASYMTEK, a Nordson company, a global leader in dispensing and conformal coating equipment and technologies, introduces the Vortik® Series of pumps that incorporates progressive cavity pump technology in a fully integrated dispensing system solution, complete with process controls for mass flow control and a patent-pending Automated Ratio Control (ARC™) system for mixing two-component fluids.

Three unique pump families in the Vortik series - VPs, VPm, and VPg - are based upon general volume ranges, and each includes models for dispensing one-component (1K) and two-component (2K) fluids. ASYMTEK's unique ARC™ technology (patent pending) in Fluidmove® software takes the guesswork out of set-up to ensure accurate mixing ratios of the 2K materials. This unique process control is done inside the dispensing platform - no need to make samples, weigh them remotely, and manually calculate mix ratios or flow rates. As a result, set-up takes less effort and 50% less time, there is less adjusting during production runs, and results are more accurate. In addition, changes in speed or volumetric output are logged, providing excellent traceability.

The Vortik VPs pump delivers industry-leading low flow rates and the smallest depositions of 1- and 2-component fluids, such as conductive epoxies, solder paste, and other adhesives used during electronics manufacturing for automotive, mobile devices, and MEMs. With a flow rate of 0.2 microliters per second, the VPs pump produces lines narrower than 300 micrometers.

The Vortik VPm and VPg pumps dispense volumes from 2 to 400 microliters/second for applications in electronics package assembly and automotive electronics, such as encapsulation, potting, bonding, sealing, and thermal grease.

Progressive cavity pump technology offers benefits that include the highest volumetric accuracy compared to other needle-based dispensing, enabling very small volumes. Because of a closed-pump design, dispensing is independent of variables like fluid pressure and ambient temperature changes, resulting in high consistency and accuracy. Dispensing is faster during production because no fluid refill cycle is needed.

The Vortik® Series of progressive cavity pumps is being introduced at Productronica 2019, the world's leading trade fair for electronics development and production, in Munich, Germany, November 12-15, 2019, in the Nordson stand A2.345.

Source: https://www.nordson.com/en/