All-solid-state batteries have recently attracted attention as an energy storage solution for electric vehicles. However, challenges still exist with these devices including short-circuiting and complicated strategies to control non-uniform lithium growth. To overcome these issues, a paper published in Advanced Science has proposed a new Ag-Li alloy anode manufactured by roll pressing.

Study: In Situ Formed Ag-Li Intermetallic Layer for Stable Cycling of All-Solid-State Lithium Batteries. Image Credit: Eakasit/Shutterstock.com

All-Solid-State Batteries: Powering the Electric Car Revolution

As the automotive industry turns toward electric power to move away from its reliance on fossil fuels, the question of battery reliability and efficiency is central to research and development. All-solid-state batteries (ASSBs) have emerged as strong candidates for energy storage devices in electric vehicles.

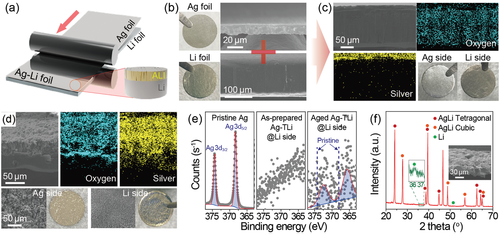

a) Experimental scheme for preparing Ag-Li alloy foil. b) Cross-sectional SEM images of the (upper) pristine Ag and (bottom) thick Li foils with corresponding digital photographs. Cross-sectional SEM images and digital photographs of the c) as-prepared Ag-TLi and d) aged Ag-TLi, and their corresponding EDS elemental mappings of oxygen and silver. Top-view SEM images of Ag and Li sides of the aged Ag-TLi are also displayed in (d). e) Ag 3d XPS spectra of the pristine Ag and Li sides of the as-prepared and aged Ag-TLi. f) XRD pattern of the aged Ag-tLi shown in SEM image (inset). Image Credit: Choi, H.J et al., Advanced Science

These sulfide-based batteries contain solidified components that are nonflammable, and the main advantage of them is that they permit the inclusion of metallic lithium as anodes. The ASSBs achieve better energy density compared to liquid-electrolyte batteries due to the solid lithium anodes. The solid electrolytes physically prevent lithium protrusion because of a higher shear modulus than liquid electrolytes.

Current Drawbacks to Solid-State Batteries

However, ASSBs are not without their issues. Despite the enhanced physical properties, short-circuiting caused by uncontrollable lithium growth in the batteries is a problem that current research has not adequately addressed. This lithium growth occurs because metallic lithium seeds form at the Li/SSE interfaces which possess interfacial voids which attract additional lithium ions which are deposited during subsequent charge cycles.

The accumulation of lithium ions in this manner causes a volume change within the solid electrolyte which inevitably leads to stress cracking. Studies have shown that once a crack occurs, lithium filament growth will lead to a short-circuit, seriously impeding the performance of the battery and shortening its lifespan.

Additionally, manufacturing processes for solid-state batteries are complex, limiting their widespread adoption by the automotive industry. This seriously impedes the commercial viability of the technology.

Improving ASSBs

To overcome this critical short-circuit issue, recent studies have proposed various approaches. Some studies have explored the use of protective layers such as artificial solid-state interphases. However, these approaches have thus far shown various limitations. They have problems with reducing dead volume in the device, have difficulty forming defect-free solid electrolyte layers, and face issues with simplifying fabrication methods.

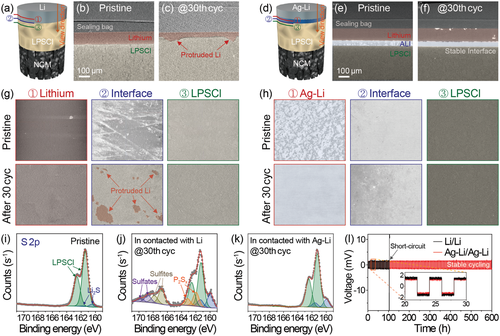

a,d) Schematic illustrations showing view direction and detection points. XRM images of the NCM/Li and NCM/Ag-Li cells at the pristine state and after 30 cycles: b,c,e-f) Cross-sectional view and g,h) top-view images at the designated points shown in (a) and (d). S 2p XPS spectra of the i) pristine LPSCl, j) LPSCl in contact with Li, and k) LPSCl in contact with Ag-Li after 30 cycles. l) Voltage profiles of Li/Li and Ag-Li/Ag-Li symmetric cells at 0.5 mA cm–2 with a fixed capacity of 1 mAh cm–2. Image Credit: Choi, H.J et al., Advanced Science

Most studies have used lithium-indium alloys as anode materials for solid-state batteries due to dendrite-free features and higher interfacial stability compared to pure lithium. However, this alloy is still difficult to implement in high-density ASSBs due to indium having a higher operating voltage than lithium (assuming that the capacity of both is the same.) Therefore, designing an anode that has low operating potential, has a dendrite-free structure, and is easy to manufacture is of central concern to researchers.

A recent concept that has been widely introduced to control the grown of dendrites in liquid lithium electrode batteries is lipophilicity. The formation of a solid buffer layer suppresses dendrite formation in the liquid. Silver, gold, and zinc have lipophilic properties and have been investigated for their ability to control the direction of lithium growth, improving the electrochemical performance of lithium structures that include them.

Based on this solid solution process, anode-free ASSBs that incorporate silver and pinhole-free solid electrolytes have been explored. These solid-state devices have improved cycling performance and exhibit reversible lithium plating/stripping processes. However, additional fabrication processes need to be employed to make these ASSBs.

Developing a Superior Lithiophilic Ag/Li ASSB Anode

To address these shortcomings, the research in Advanced Science has presented a novel ASSB with a silver-lithium anode fabricated with a simple, scalable roll pressing process.

The anode contains an in situ formed intermediate silver-lithium layer formed from silver and lithium foils. This formed a stable interface at the solid-state battery’s anode side. The intermediate layer contained a considerable amount of silver, which, due to its lipophilic properties, suppressed lithium dendrite growth and enhanced the formation of the stable interface with the sulfide solid electrolytes.

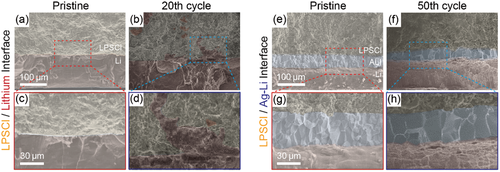

Cross-sectional low (top row) and high (bottom row) magnified SEM images of the a–d) LPSCl/Li and e–h) LPSCl/Ag-Li interfaces of the NCM cells with Li metal and Ag-Li alloy anode at the pristine state and after 20 and 50 cycles. Image Credit: Choi, H.J et al., Advanced Science

Additionally, uneven lithium dendrite growth was further controlled by the silver that did not form the intermediate layer by participating in the solid solution reaction. The results of the study demonstrated attractive properties of this novel anode. Capacity retention was improved, at 94.3% over 140 battery cycles. Additionally, even under harsh conditions, stable cycling was achieved, circumventing the short-circuit issue in cells that use metallic lithium.

The Future

The research presented in Advanced Science introduces a novel stable silver-lithium alloy anode for solid state batteries that can be manufactured in situ via a simple, scalable fabrication process. The solid, functional interface layer in the anode prevents lithium protrusion during cycling, vastly improving the life cycle of the battery and reducing the risk of short-circuiting, improving the performance and commercial viability of sulfide-based ASSBs.

Further Reading

Choi, H.J et al. (2021) In Situ Formed Ag-Li Intermetallic Layer for Stable Cycling of All-Solid-State Lithium Batteries [online] Advanced Science | onlinelibrary.wiley.com. Available at: https://onlinelibrary.wiley.com/doi/full/10.1002/advs.202103826

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.