Intelligent food packaging has the potential to advance the field of food science, providing materials with unique properties that surpass conventional packaging. Writing in the journal Polymers, a team of scientists from Malaysia’s Universiti Kebangsaan and Tunku Abdul Rahman University College has presented research into the development of a starch/polyaniline biopolymer packaging with intelligent colorimetric ammonia sensors.

Study: Starch/Polyaniline Biopolymer Film as Potential Intelligent Food Packaging with Colourimetric Ammonia Sensor. Image Credit: Goncharov_Artem/Shutterstock.com

Conventional Food Packaging Issues

Currently, most food packaging is manufactured from plastic, which is typically derived from petrochemicals. The production of plastic packaging for the food industry is problematic as it is a cause of greenhouse gas emissions, and plastic waste proliferates in the environment due to its non-biodegradability, breaking down into microplastics in the ocean, releasing toxic by-products, causing environmental damage, and endangering the food chain.

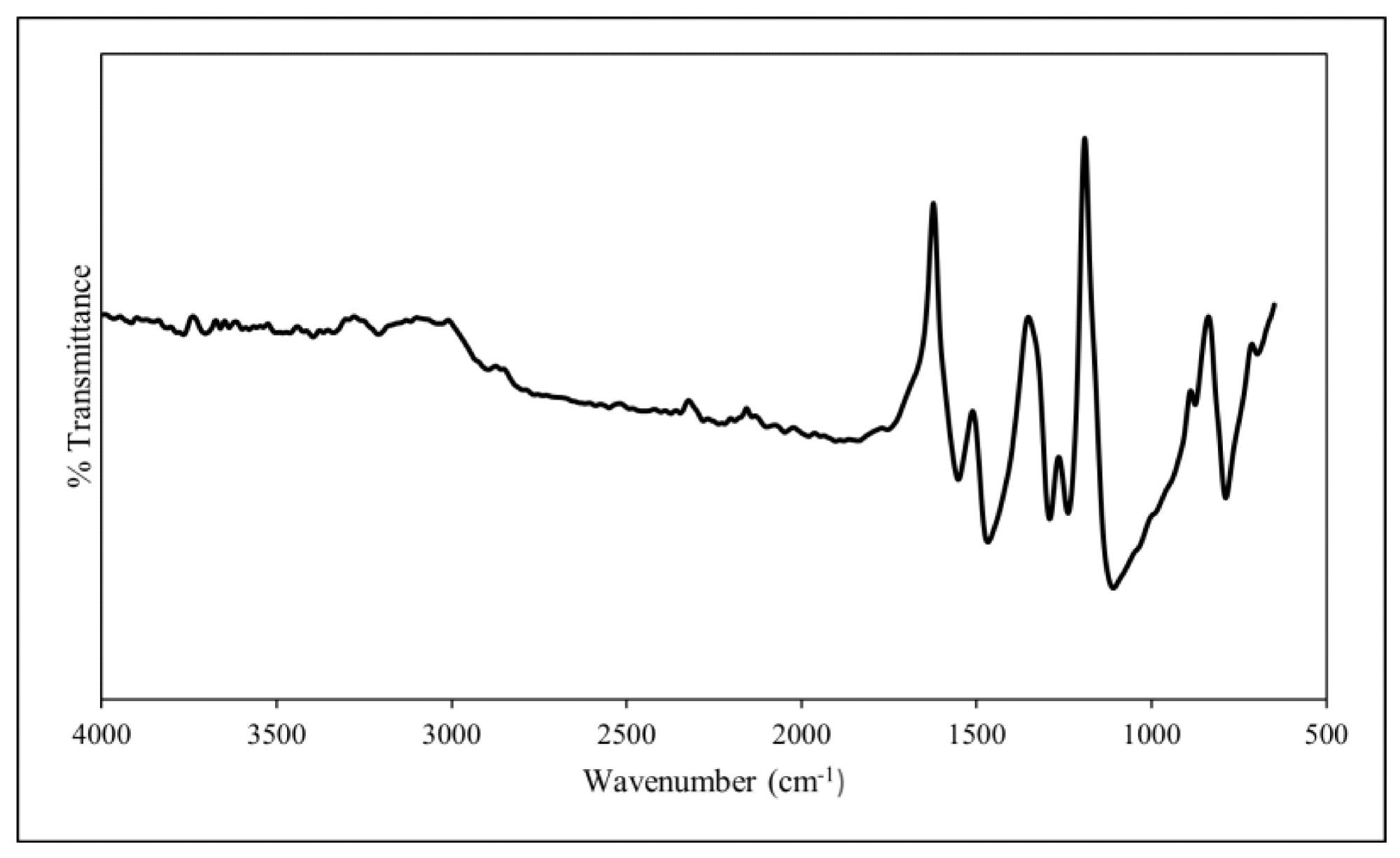

FT-IR spectrum of PANI. Image Credit: Chia, M.R, et al., Polymers

Additionally, a key concern in the food industry is food safety due to the potential for spoilage by microbial and chemical agents. The sensorial properties and quality of food become affected, and the risk of food-borne disease can have huge implications for the health of populations. Several labels which indicate when food becomes unsafe to eat are used, but these can cause confusion for consumers, leading to perfectly edible food being wasted by mistake.

Use-by dates are not an absolute indicator of food safety, as different storage conditions can affect the shelf-life of food, with food stored in modern refrigeration units still safe to eat past the date on the packaging. According to figures by the Food and Agriculture Organization, around one-third of all the world’s edible food is wasted every year. This causes additional problems with waste and contributes to global warming due to the breakdown in packaging and food.

Biopolymers and Sustainable, Intelligent Food Packaging

The scale of the issues with food packaging and waste has facilitated research into biopolymers and intelligent food packaging. Biopolymers reduce fossil fuel use and emissions, are derived from abundant, renewable resources, are non-toxic, are easily manufactured, and their biodegradability helps to overcome the issues with polymer waste accumulation in the environment. Cellulose and starch are the main biopolymers used for green food packaging.

Intelligent food packaging provides significant advantages for the food industry. Bio-sensing abilities can be incorporated into materials to detect food quality and provide a more accurate indicator of food spoilage and shelf life, removing the confusion faced by consumers over conventional food labeling.

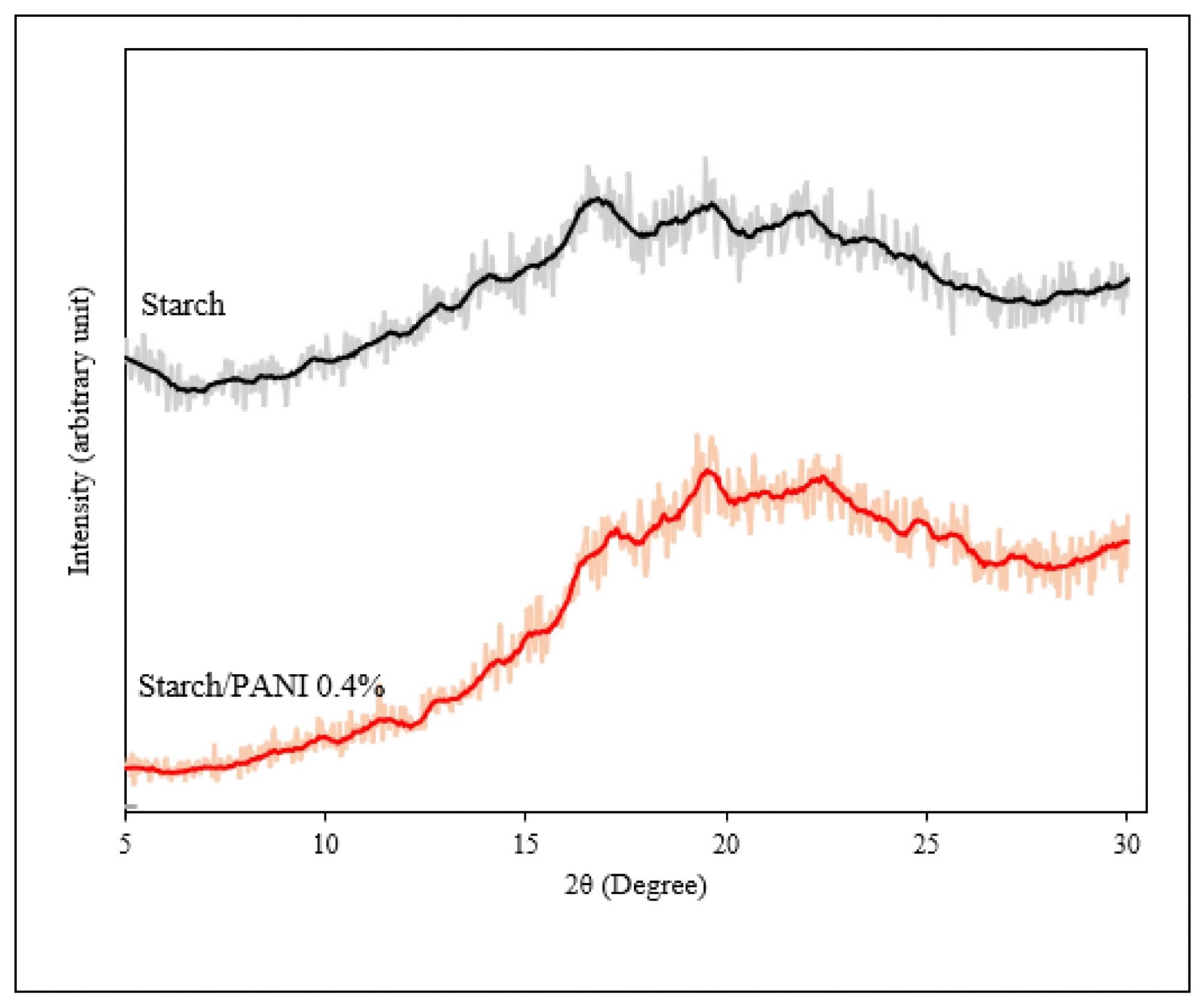

XRD diffractograms of starch and starch/PANI 0.4% polymer films (The actual experimental data and smoothed data were represented by the shadow and solid lines, respectively). Image Credit: Chia, M.R, et al., Polymers

Various natural materials with colorimetric properties have been explored in the manufacture of intelligent packaging as sensor elements, including natural dyes such as curcumin, alizarin, and anthocyanin. However, these natural dyes degrade over time when exposed to the environment, and they possess limited sensitivity, with fluctuations in sensitivity depending on the extraction source. Moreover, when they degrade, they can leach into food, leading to contamination.

The challenges currently faced by researchers when designing intelligent, sustainable food packaging have facilitated the search for safer alternatives that possess superior food quality indication abilities.

The Study

In the current research, the authors have investigated the development of a safe and effective green intelligent food packaging sensor solution that has vast potential for reducing waste and improving sustainability in the food industry.

The research has focused on polyaniline, which is an attractive candidate due to its eco-friendliness, reliability, simplicity, and lack of leaching into foodstuffs. Studies have already demonstrated that HCl-doped polyaniline nanofibers are non-toxic to the toad species Rhinella arenarum, even at high concentrations. Additionally, studies have indicated mild cytotoxicity toward mouse embryonic fibroblasts.

Studies have demonstrated that the cytotoxicity of polyaniline is due to residual substances. Rinsing it well reduces its toxicity, making it suitable for use as an additive in food packaging. The oxidation state of polyaniline is affected by pH, which is an indicator of spoilage as ammonia is released by bacteria in food. This causes a color change in the material, which can be used as the basis of a colorimetric sensor for intelligent food packaging.

The authors prepared starch-polymer matrix materials impregnated with polyaniline as a colorimetric food spoilage sensor. A stumbling block with starch-polymer matrixes which prevent their use as quality indicators is their high electrical resistivity, facilitating the incorporation of non-invasive and leach-free polyaniline to manufacture environmentally friendly food packaging which can accurately detect ammonia, and therefore food spoilage.

Ex-situ polymerization was used to synthesize the starch/polyaniline films with successful incorporation of the polyaniline into the starch matrix. Results of their characterization tests demonstrated that the polyaniline increased the matrix’s thermal stability and enhances the film’s amorphous characteristics.

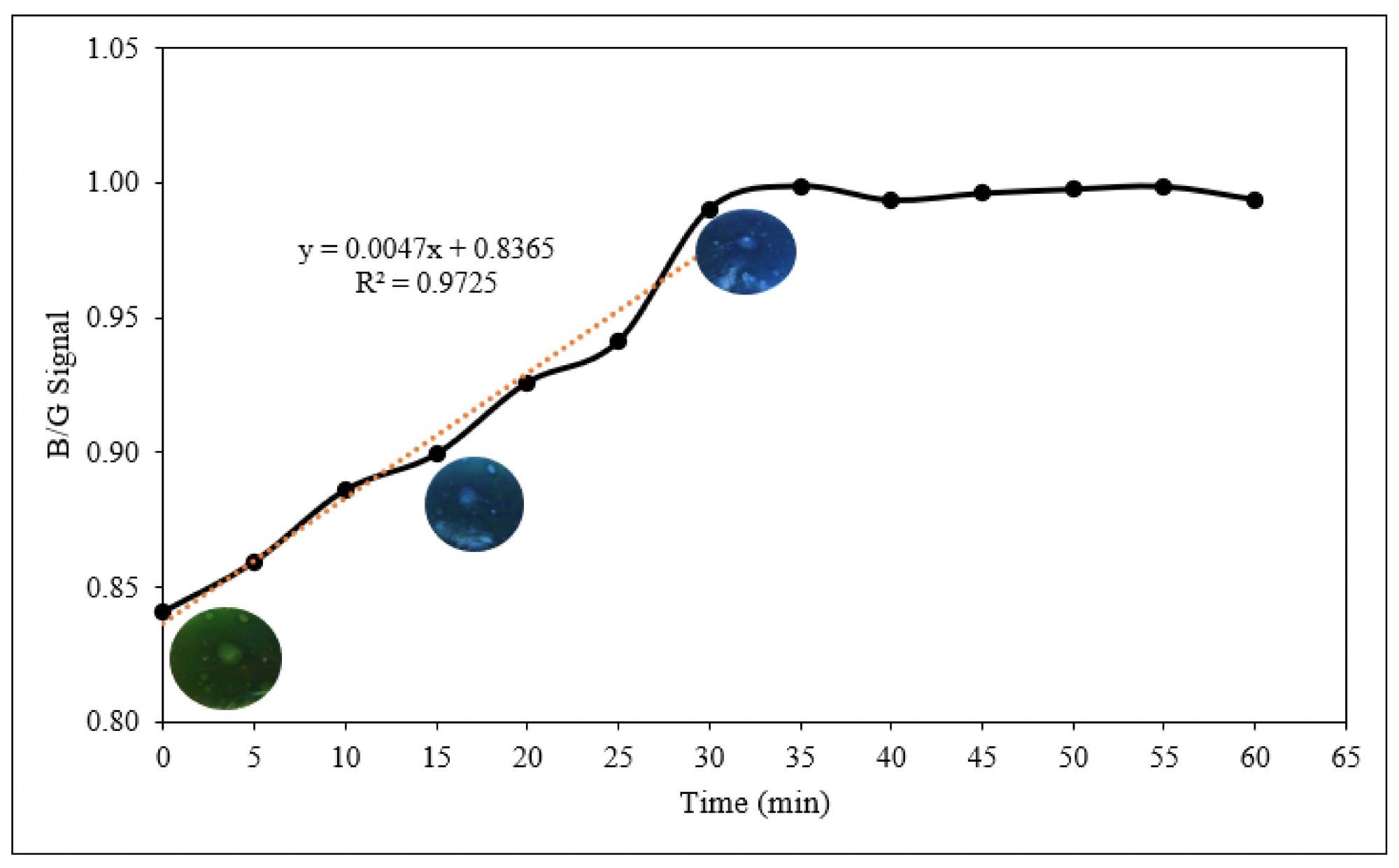

The response time of starch/PANI 0.4% film towards 600 ppm ammonia solution. Image Credit: Chia, M.R, et al., Polymers

A significant color change from green to blue was observed upon exposure to ammonia vapor, with high precision and good linearity. High sensitivity, selectivity, and low limit of detection for ammonia vapor were observed. Based on their findings, the authors have stated that the starch/polyaniline film has significant potential for the manufacture of safe, environmentally friendly, sustainable, intelligent food packaging.

Further Reading

Chia, M.R, Ahmad, I & Phang, S.W (2022) Starch/Polyaniline Biopolymer Film as Potential Intelligent Food Packaging with Colourimetric Ammonia Sensor [online] Polymers 14(6) | mdpi.com. Available at: https://www.mdpi.com/2073-4360/14/6/1122

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.