A group of researchers led by the University of Texas at Arlington assistant professor is building a predictive tool that will help assess the lifespan, robustness, and safety of composites used in the construction of aircraft.

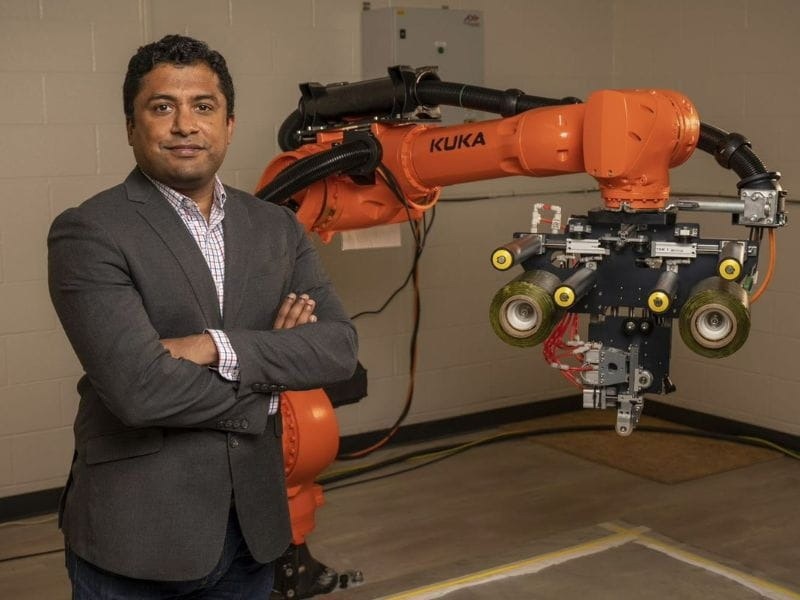

Paul Davidson. Image Credit: University of Texas at Arlington.

The $379,500 US Air Force Research Laboratory (AFRL)-funded project was led by Paul Davidson, assistant professor in the Department of Mechanical and Aerospace Engineering (MAE).

Our aim is to make lighter aircraft more durable while ensuring flight safety.

Paul Davidson, Assistant Professor, Department of Mechanical and Aerospace Engineering, University of Texas at Arlington

According to Davidson, the industry is increasingly using layers upon layers of composite materials bonded together to build lighter and stronger airplanes. For instance, the Boeing 787 contains around 50% composite materials. The risk of delamination, or the separation of those many layers, which might be brought on by operating circumstances and impact hazards, is the difficulty in employing composites.

Davidson compares delamination to a windshield crack in a car:

Eventually, that crack grows and grows and makes the vehicle unsafe. We’re trying to tell the driver how much time before it becomes unsafe or needs to be strengthened or replaced.

Paul Davidson, Assistant Professor, Department of Mechanical and Aerospace Engineering, University of Texas at Arlington

According to Davidson, the idea has uses in both the military and the commercial sectors.

Davidson says, “The military wants to more finely tune the service life of these composites. They want to know how durable our materials are and how fast can we put the aircraft back into action.”

Field experts will assess the extent of the aircraft damage using ultrasound equipment. This information will be used by Davidson’s developed predictive tool for computational tests to calculate the composite structure’s operating life and failure risk. The study also seeks to provide answers to the issues of what repairs are necessary, how long it will take to complete those repairs, and whether the aircraft is now safe to fly.

“The data obtained from the field teams is often incomplete. I’m infilling missing data using machine learning and computational tools to determine composite life, durability and safety. We’ll do the impacts and stress tests on the aircraft composites virtually,” Davidson adds.

Under the auspices of the AFRL’s Structural Integrity Research Collaborations for Aircraft program, the work will be carried out in the Laboratory for Advanced Materials, Manufacturing, and Analysis at UTA.

The effort by Davidson is crucial to flight safety for both the military and civilians, according to MAE chair Erian Armanios.

It’s best to virtually extend the range and scale of tests, where loss of aircraft and life is eliminated. This project is cost-effective and lifesaving. It also brings UT Arlington to the forefront of computational composite testing, which will continue to grow in coming years.

Erian Armanios, Chair, Department of Mechanical and Aerospace Engineering, University of Texas at Arlington

Source: https://www.uta.edu