The increased growth in the development and use of plastic pipes for oil pipelines, gas and water distribution, and ducting for telephone and electrical cables, etc. has created a need for a vast range of mechanical testing to make sure that the product employed is most suitable for its particular function and at the same time can survive all the stresses caused by extreme temperature fluctuations and underground land shifts.

Testometric provides a complete test system for carrying out the specialized tests necessary for assessing such products.

Please click here if you would like more information on the instrument used in this article or a quote

Please click here if you would like more information on the instrument used in this article or a quote

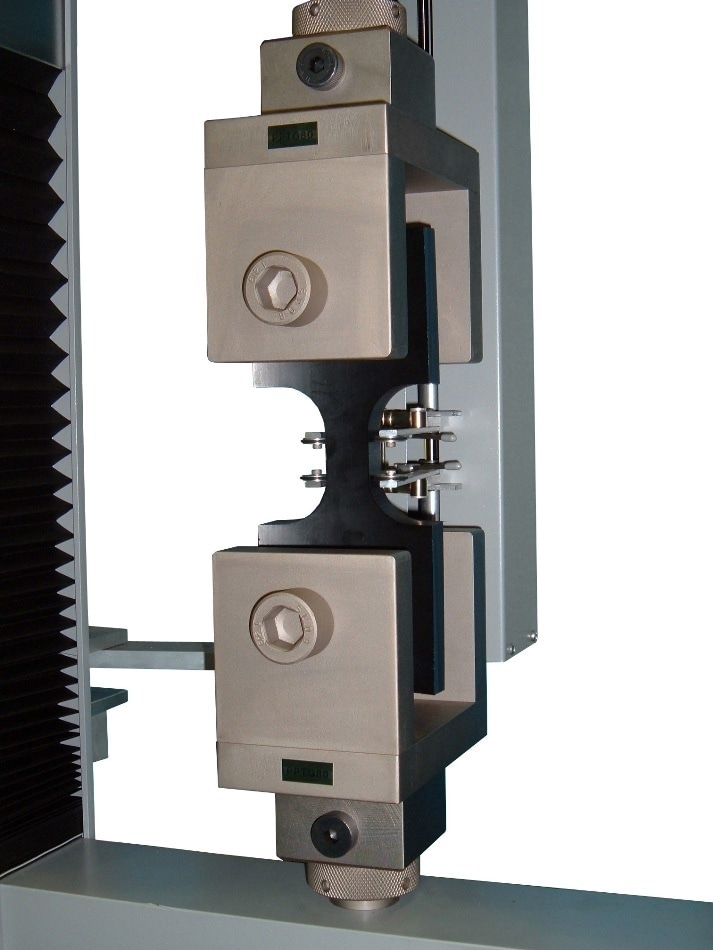

Grips

Testometric offers an extensive range of grips for performing compression tests on pipes up to 1600 mm diameter, tensile tests on thick wall and thin wall pipes, hook tensile tests, peel on multi layer pipe and so on.

Extensometry

Various custom built extensometers are available that can function on thick- or thin–walled pipe sections.

Software

Testometric also provides an extensive pipe test software with pre-defined calculations to international standards. They include tensile strength, tensile ring strength, ring stiffness, hook strength, creep/crack detection, peel strength, and long term prediction values.

Configurable test methods are as follows:

- ASTM F1281 Standard specification for cross-linked polyethylene/ aluminum/cross-linked polyethylene (PEX-AL-PEX) pressure pipe

- ASTM F1281 Standard specification for cross-linked polyethylene/ aluminum/cross-linked polyethylene (PEX-AL-PEX) pressure pipe

- ASTM F1282 Standard specification for polyethylene/aluminum/ polyethylene (PE-AL-PE) composite pressure pipe

- ASTM D1785 Standard specification for poly (vinyl chloride) (PVC) plastic pipe, schedules 40, 80 and 120

- ASTM D2105 Standard test method for longitudinal tensile properties of reinforced thermosetting resin pipe and tube

- ASTM D2290 Standard test method for apparent hoop tensile strength of plastic or reinforced plastic pipe by split disk method

- ASTM D2290 Standard test method for apparent tensile strength of ring or tubular plastics and reinforced plastics by split disk method

- ASTM D2412 Standard test method for determination of external loading characteristics of plastic pipe by parallel-plate loading

- ASTM D2412 Standard test method for external loading properties of plastic pipe by parallel-plate loading

- ASTM D2513 Standard specification for thermoplastic gas pressure piping systems

- WIS4-32-13 Appendix D: Method for the determination of tensile yield stress and elongation at break

- WIS4-32-17 Water Industry Specification. Polyethylene pressure pipes for pressurized water supply and sewerage duties

- EN253 Compressive strength, axial shear strength, tangential shear strength etc.

- EN802 Plastic piping and ducting systems. Injection-molded thermoplastics fittings for pressure piping systems

- Test method for maximum deformation by crushing

- EN1394 Heading not known. Test methods for GRP pipes

- EN1979 Structured pipe seam tensile tests

- BS2782 BS EN ISO9967 Thermoplastics pipes – Determination of creep ratio

- BS2782 BS EN1446 Plastics piping and ducting systems – Thermoplastics pipes – Determination of ring flexibility

- ISO 3501 Assembled joints between fittings and polyethylene (PE) pressure pipes – Test of resistance to pull out

- ISO 6259 Tensile properties of thermoplastic pipe

- BS5480 Glass reinforced plastics (GRP) pipes, joints and fittings for use for water supply or sewage

- ISO9969 Thermoplastic pipes – Determination of ring stiffness

- ISO 9969 Thermoplastic pipes – Determination of ring stiffness

- prEN13476-1 Plastics piping systems for non-pressure underground drainage and sewerage – Structured-wall piping systems of unplasticised poly (vinyl chloride) (PVC-U), polypropylene (PP) and polyethylene (PE) – Part 1: Specifications for pipes, fittings and the systems

- ISO13953 Polyethylene (PE) pipes and fittings – Determination of the tensile strength and failure mode of test pieces from a butt-fused joint

- DIN16961 Thermoplastics pipes and fittings with profiled outer and smooth inner surfaces. Part 1: Dimensions

- DIN16961-2 Thermoplastics pipes and fittings with profiled outer and smooth inner surfaces. Part 2: Technical delivery conditions

- DIN16961 Thermoplastics pipes and fittings with profiled outer and smooth inner surfaces. Part 2: Technical delivery conditions

Testometric materials testing machines

This information has been sourced, reviewed and adapted from materials provided by Testometric Company Ltd.

For more information on this source, please visit Testometric Company Ltd.