Primary Methodology

1. Cleave cover slip glass to identical size as GaAs device area.

2. Epoxy glass cover slip to top surface (device side) of GaAs apparatus.

*Reduce epoxy interface with the assistance of sample clips

*Utilize the minimum possible quantity of epoxy

3. Sliver epoxy GaAs apparatus with cover slip onto polishing stub, allowing 2-4 mm to overhang.

*Utilize the minimum possible quantity of epoxy

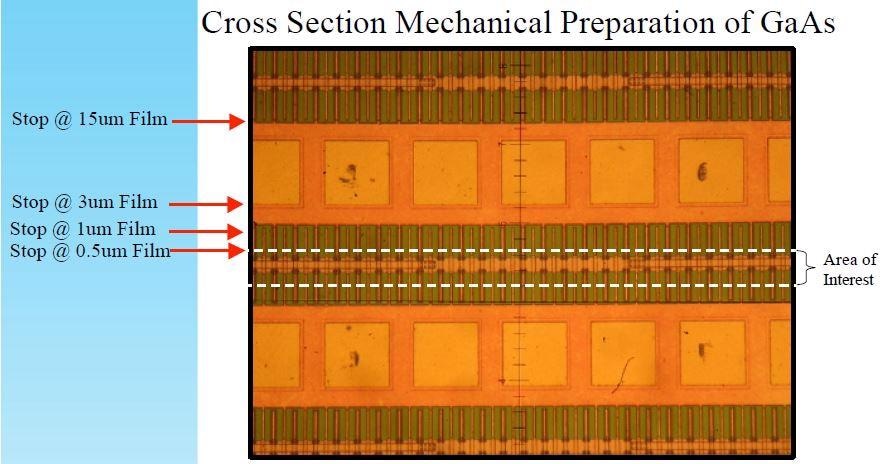

4. Commence polishing using 15 μm diamond lapping film. Utilize the above diagram as a polishing stop guide for each abrasive size. Polishing platen speed needs to be 50-60 RPM, and polishing orientation should be coextensive with sample interface.

5. Undertake final polishing using CS1 colloidal silica on MultiTexTM cloth for 10-15 minutes. Polishing platen speed needs to be 50-60 RPM and polishing orientation should be perpendicular to sample interface, commencing from the base of GaAs apparatus toward glass cover slip.

This information has been sourced, reviewed and adapted from materials provided by Ted Pella, Inc.

For more information on this source, please visit Ted Pella, Inc.