QTec® - Reinventing Vibrometry

QTec® revolutionizes laser vibrometry by eradicating the principal cause of noise, delivering superior optical sensitivity, facilitating high fidelity measurements across all surfaces.

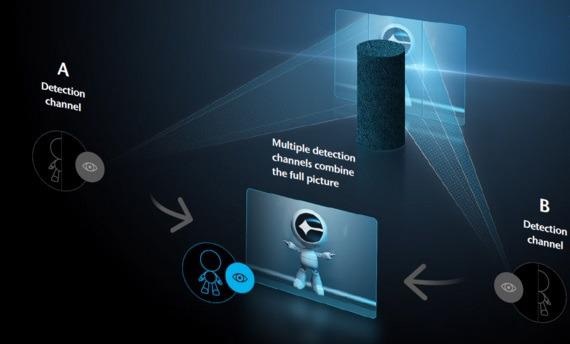

Multiple detection channels of QTec combine the full picture of vibration dynamics. Image Credit: Polytec Ltd.

QTec vibrometers use an innovative multi-path interferometer to achieve the best possible results while utilizing the best possible signal of each path. This patented technology incorporates the exceptionally well-trusted infrared Xtra sensor design for easy, rapid measurements with consistent results.

QTec® - Reinventing vibrometry

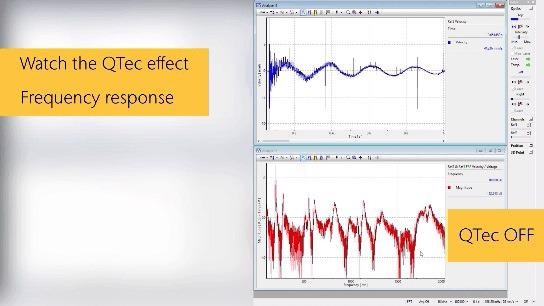

Video Credit: Polytec Ltd.

Influence of Surface Properties

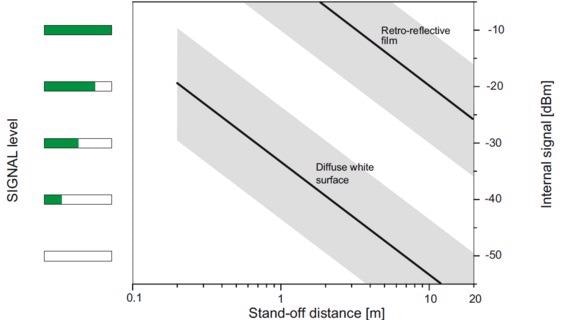

The quality of a laser vibration measurement signal relies on the intensity of the light being returned. The surface dictates the spatial distribution of backscattered light, and therefore the information the photodetector receives relative to its spatial position.

The signal level in optical tests is determined by reflectivity and working distance. Image Credit: Polytec Ltd.

The QTec® Effect

The latest, patented and pioneering technology QTec® from Polytec considerably improves the signal-to-noise ratio (SNR). QTec® resolves even the tiniest details in the measurement signal, enabling simplified post-processing.

Better signal to noise ratio (SNR) with QTec. Image Credit: Polytec Ltd.

QTec® enhances the results for practically any measurement and is especially advantageous for engineered surfaces that move laterally or rotate. A drastic reduction in the average count can be achieved for the acquisition of the same SNR while measures are unfettered by the surface properties.

Speckle Effect on Engineered Surfaces

On an optically smooth surface, the reflected laser light is returned without loss to the photodetector. In the real world, measurements are often carried out on surfaces that are optically rough. Here the light is no more reflected but scattered, containing dark and bright speckles and the laser point starts looking grainy.

The solution: change your perspective. Image Credit: Polytec Ltd.

This pattern changes with the particular perspective of an observer. This causes changes and occasionally, no light return at the photodetector. These effects can cause broadband noise and unwanted dropouts with optical measurements.

The Solution: Change the Perspective

The QTec® heterodyne multi-path interferometer offers the precise capability to prevent a reduction in the signal at the photodetector by utilizing multiple detectors. Each detector acts as an observer with a singular perspective and thus produces a unique speckle pattern.

Due to the pattern being random, it can be seen that the amalgamation of the signals from the spatially distributed detectors leads to a signal level that is statistically more stable.

With multiple detectors, QTec achieves high and stable signal level and best noise level performance. Image Credit: Polytec Ltd.

The advantages of this so-called Diversity Reception are relative to all engineered surfaces.

High speed electronics in the sensor head detect and capture the signals in real-time and only the optimal part of the signal is transmitted to a common output, making QTec® sensor heads compatible with present model single channel vibrometer decoders.

The capacity that QTec® possesses in order to provide fast, easy and robust results while independently measuring the surface properties makes it a sound choice for all applications.

QTec provides the same performance 4x faster. Image Credit: Polytec Ltd.

Related Products

VibroFlex

With the modular laser vibrometer VibroFlex, Polytec presents a new flexible approach in optical vibration measurement with an adaptable modular sensor solution that adjusts to the users' requirements.

With the addition of microscope objectives, it is possible to observe tiny structures or measure noise, vibration, harshness (NVH) on large, intricate samples, including machinery and motors.

Find out more on acoustics and vibration phenomena in research and product development and accelerate time-to-market or reliably inspect production parts in-line on a cost-effective basis. Discover how the new and patented QTec® multi-path interferometry boosts the limits for optimized SNR.

This information has been sourced, reviewed and adapted from materials provided by Polytec.

For more information on this source, please visit Polytec.