With the utilization of 6-sigma Quality Improvement Programs, process upgrades often benefit from implementation of higher-level process chemical analyzers. Petrochemical, refineries, polymerization, pharmaceutical, and specialty chemical operations improve from real-time analyzers for tightening trim controls of the process.

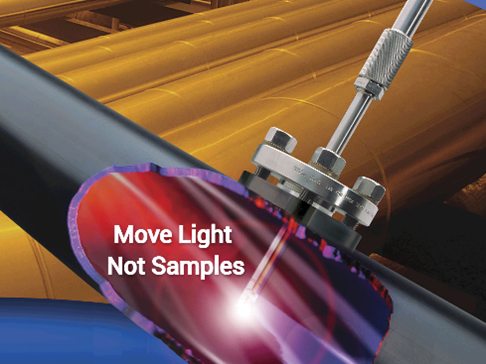

Image Credit: Process Insights - Optical Absorption Spectroscopy

Process Insights™ specializes in GUIDED WAVE™ fiber optic coupled process chemical analyzers to high-performance optical probes and flow cells eliminating traditional sampling systems that usually require maintenance. These same optical sample interfaces are available for improving the precision performance of other brands of process spectrometers and photometers as well. Remember, signal to noise translates to improved measurement precision, the basis for increasing product quality, process credits and reducing waste.

The optical sample interface consists of either an extractive sample conditioning system with flow cell, or an inline probe for direct in-situ monitoring. When sample systems fail, reliable measurements stop, resulting in system downtime that is not necessarily the analyzer’s fault. Sample systems have their place and should be used when process streams are particulate-laden wet (2-phase), or overly temperature sensitive. Otherwise inline probes are the most cost effective and trouble-free solution to real-time process spectral analysis.

While an insertion probe approach can often reduce installation costs, sometimes safety, servicing, and/or sample conditioning requirements make it necessary to integrate a sampling loop or slip stream. Flow Cells are preferred whenever:

- direct insertion probes are inappropriate and

- the required optical path length is 30 mm or greater

Questions to Help Determine the Probe or Flow Cell Needed

There are considerations when buying a probe or flow cell for an FT-NIR, NIR or UV-VIS process analyzer system. Knowing the sample type such as, gas or fluid is the place to start. Then the expected chemical concentrations along with temperature and pressure ranges of your application are needed. The process environment needs to be reviewed with the number of locations to be monitored. Also, are safety certifications needed? Knowing the answer to these top-level questions will speed the buying process and assure you make the right decision for your process monitoring needs. Process Insights has specialists to help with your process probe selection.

7 Questions to Consider when Buying a Probe or Flow Cell for an FT-NIR, NIR or UV-VIS Analyzer System:

- Is your sample a gas or fluid? If fluid, is it pure liquid, emulsion, or slurry?

- What is the expected concentration range of the chemicals in the sample stream?

- What are the pressure and temperature ranges of the sample stream?

- Will a few degrees of temperature variation at the sample interface impact the process?

- Will the sample interface be installed in a highly corrosive environment?

- How many locations do you want to monitor?

- Does your analyzer system need any third-party safety certifications? (CRN, CSA, ATEX, IECEX)

Based on answers to these questions there are a variety of optical insertion probes and flow cells that will provide the best solution for your application.

Process Insights offer a range of sample interfaces (probes and flow cells) that are designed with unique features to ensure accurate and reliable measurements in a variety of applications. One unique feature of our GUIDED WAVE sample interfaces is their flexibility in design. They can be customized to fit specific process requirements, such as temperature and pressure, and to accommodate various sample types, including liquids, slurries, and gases. Additionally, they are designed to be easy to install and maintain, minimizing downtime and reducing operating costs.

Sample Interface: Probe and Flow Cell Product Options

- Several probes have auxiliary features

- All are compatible with Process Insights FT-NIR, NIR, UV-VIS analyzers

- All are compatible with most other fiber optic-based analyzer brands

- Most can be optimized for UV-VIS or NIR spectral regions

- Most can be customized with fiber diameter and connectors to match the optical ranges

- Meets ANSI/ISA dual seal requirement and IEC 60079-28 standard

- Some are certified to ASME and CRN pressure vessel standards

Insertion Probe Options

Source: Process Insights - Optical Absorption Spectroscopy

| . |

. |

|

|

SST Insertion Probe

Single Sided Transmission

- Standard Continuous Process Measurement Probe

- Metal braze seal

- Can be installed in reactor vessels

- Compatible with Gear Driven Extractor

- Market-leading optical efficiency

- ¾ inch or 1-inch diameter

- Maintenance video on YouTube

|

|

|

O-SST Insertion Probe

O-ring Single Sided Transmission

- Internal O-ring Seal

- 1-inch diameter

- Recommended for corrosive process streams containing strong acids, bases, or cyanides

|

|

|

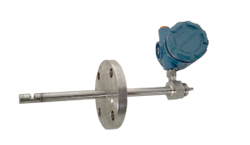

Resistance Temperature Detector (RTD-SST) Process Probe

- Plants or reactors without available access ports gain additional process analytical tool

- Better temperature compensation for NIR measurements than having an RTD and NIR probe installed on separate flanges

- Available in multiple configurations

- Temperatures to 300 °C

- Pressures to 2000 psi or 138 bar

|

|

|

Shuttle Process Probe

- Installed in the process pipe

- Slides in/out of the process for service

- Often used in the polymer industry

|

|

|

Turbidity Insertion Probe

- Measures 90° backscattering

- Designed for many refinery applications

- O-ring seals

- Typical for fuel color or cloudiness

|

|

|

Vapor Probe

- New design prevents condensation on lenses

- Used for H2O2 sterilization monitor

- Flanged and flangeless offerings

|

Flow Cell Product Options

Source: Process Insights - Optical Absorption Spectroscopy

| . |

. |

|

|

MPFC Multipurpose Flow Cell

- Our standard flow cell

- Available in multiple pathlengths

- Ideal for most refinery and petrochemical applications

- Maintenance video on YouTube

|

|

|

Axial Flow Cell

- For applications with long Pathlengths

- May be installed at a slight angle to prevent bubble formation if this is an issue

- An example application is phenol breakthrough in bromide plant

- Or the measurement of HNO2 in Fertilization plants

|

|

|

Gas Flow Cell

- Longer pathlength for monitoring gases

- Many materials of construction

|

|

|

High Safety Flow Cell (HSFC)

- Contains sniffer port for early warning leak detection

- For applications involving extremely hazardous materials

- Patented Double o-ring seals for added durability

- Built into a ½” class 300 flange

- Standard optical pathlength is 20 mm and 30 mm

|

|

|

Teflon Flow Cell

- For applications not compatible with metals

- Performs well in corrosive streams containing strong acids, bases, peroxides, or halogenated compounds

- Ideal for processes where even parts per billion levels of metals contamination can create serious problems as in semiconductor fab etching and cleaning steps

- Teflon-to-Teflon seal reduces the chance of leaks

|

|

|

Teflon PFA / PEEK

- Designed for hydrofluoric applications

- For applications where Teflon and metal are not compatible

- Typically used in semiconductor applications

|

|

|

Teflon Axial

- For applications where pathlength is greater than 25 mm and small flow, volumes are required

- For applications not compatible with metal

- Great for applications where trace metal sensitivity is required

|

|

|

Turbidity Flow Cell

- For fuel color and turbidity application

- Collects 90-degree scatter light

- Clean out port included for ease of window cleaning

|

|

|

Heated Flow Cell

- For applications such as polymers where temperature control is critical

- Can be used to maintain the temperature of a preconditioned sample

- For use with process temperatures up to 300 ○C

|

Sample Interface Product Option

Source: Process Insights - Optical Absorption Spectroscopy

| . |

. |

|

|

Cuvette Holder

- Ideal for use with the the LAB 508 UV-VIS™ Benchtop Spectrometer or NIR-O™ Process Analyzer Spectrometer

- For method development and system validation

- Use with standard cell pathlengths of: 5 mm, 10 mm or 20 mm

- Works well with multi-channel lab analyzers such as LAB NIR-O

- New tri-cuvette holder released

|

Process Insights offers a large variety of process spectroscopy insertion probes and flow cells that meet the harsh demands of the process environment. The above list provides a general overview. For the full product line, specifications, and downloadable data sheets visit https://www.process-insights.com/products-3/products-industrial/nir-uv-vis-process-and-lab-analyzers/probes-and-flow-cells/.

Or to receive specific application help complete our online questionnaire at https://www.process-insights.com/products-3/products-industrial/optical-absorption-spectroscopy-process-lab-analyzers/application-questionnaire/.

This information has been sourced, reviewed and adapted from materials provided by Process Insights – Optical Absorption Spectroscopy.

For more information on this source, please visit Process Insights – Optical Absorption Spectroscopy.