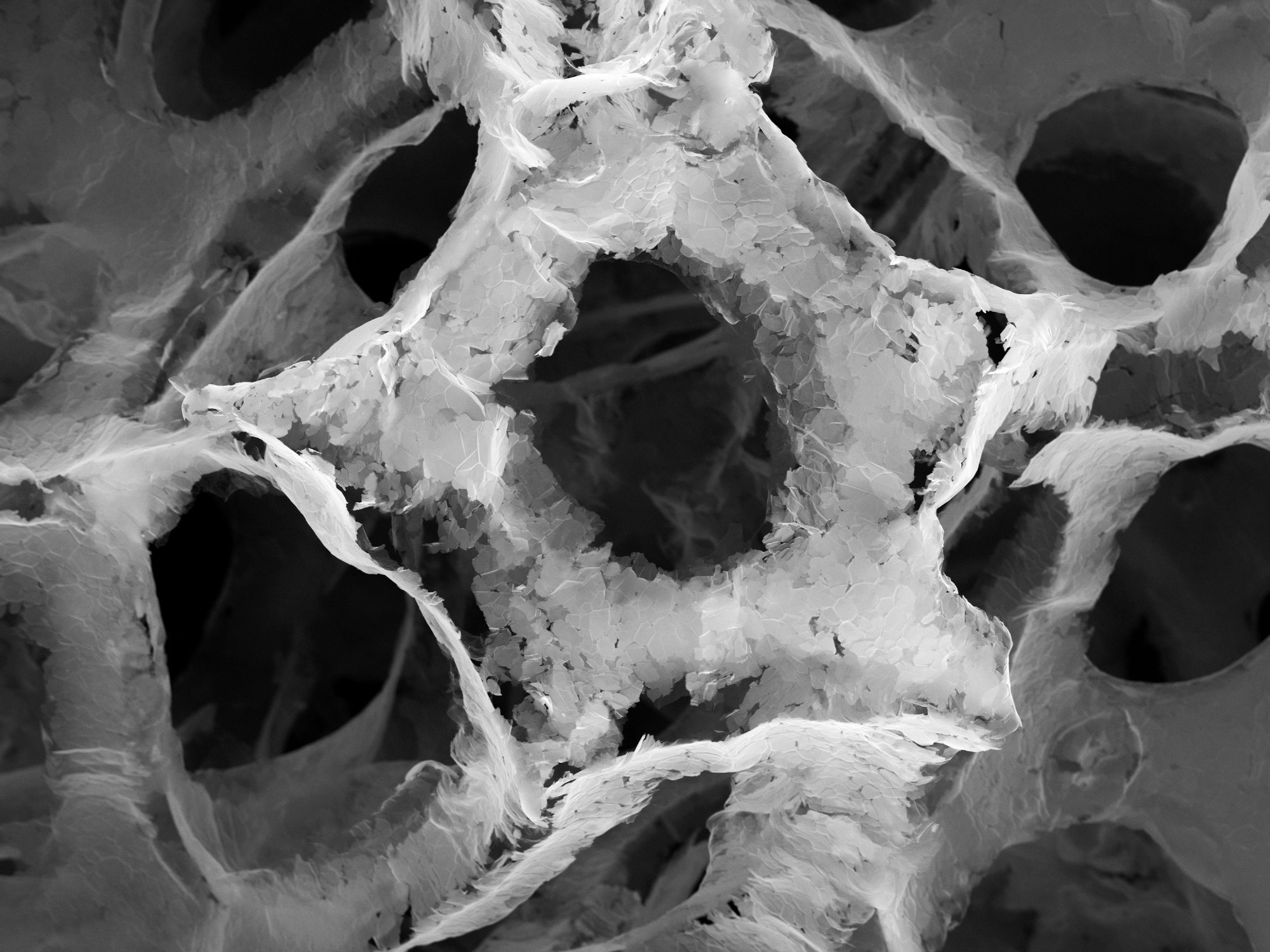

A new category of metal, three-dimensional (3D) porous metals, has recently garnered a great deal of interest. Often made from titanium or iron alloys, such materials have a highly porous structure formed via a network of 3D continuous ‘tunnels’ that permeate the material. These networks of empty regions within the material structure mean that the final material has a high surface area and porosity and can be used in applications such as nanoreactors for chemical catalysis1 or as a biomaterial.2

Image Credit: Shutterstock.com/bartu

The network of 3D tunnels within the material is known as a 3D bicontinuous structure, and the shape and dimensions of these structures are very important for determining which type of chemical compounds can permeate through the material. At present, trying to find synthetic methods that would help provide a particular 3D bicontinuous structure is a highly active area of research, as control over the network formation would help tune the creation of such materials for specific applications.3

The challenge is characterizing these 3D bicontinuous structure networks. Most of the channels will be internal to the material, and so many imaging techniques that are only sensitive to the surface structure and atomic arrangements will not be able to visualize the shape and size of the tunnels.

As the bicontinuous structure networks are also 3D in their nature, the imaging technique needs to be able to recover 3D information. In this article, we explore the use of X-Ray computed tomography (CT) as a non-destructive imaging technique to visualize the internal structures of these metals. Image processing software is then used to reconstruct the tunnel network and measure mass-transport parameters such as tortuosity.

X-Ray Computed Tomography

One of the most common ways of characterizing 3D bicontinuous structures in metals is X-Ray computed tomography (CT). This method of characterization can be used to reconstruct a full 3D image of a sample, including its interior structure.4 By collecting a series of 2D radiographs, known as slices, from many different viewing angles, a computer algorithm can then be used to reconstruct a full 3D structure from these projections.

The advantage of X-Ray CT is that the energetic X-Rays have a good penetration depth through the material, so they can be used to visualize not just the surface structure but also internal structures such as the 3D bicontinuous networks.

X-ray CT is often performed using a synchrotron as the source of X-Ray radiation. Using synchrotron sources means that excellent energy tuneability, high photon doses and the beams can be focused to achieve small spot sizes to improve the spatial resolution of methods such as X-Ray CT.

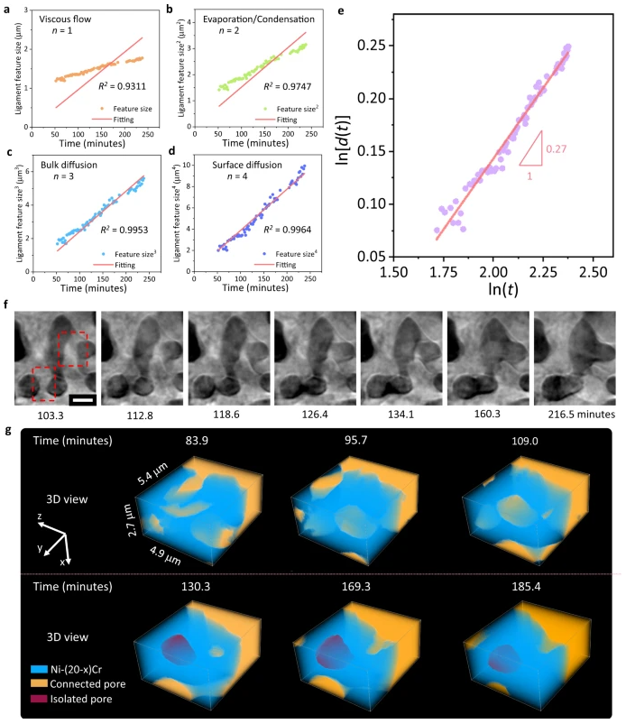

Recently, a team of scientists used in-situ X-Ray nano-tomography to visualize the formation of 3D bicontinuous structures in molten salt formed by the dealloying process of a nickel-chromium alloy in potassium-magnesium chloride salts.5

This figure displays molten salt dealloying (MSD) and a direct observation of enclosed void formation. Image Credit: Liu, X., et al. https://doi.org/10.1038/s41467-021-23598-8

Results

Dealloying methods are one way to create materials with 3D bicontinuous structures of nanopores, and they are crucial when it comes to producing lightweight, high-density energy storage materials.

Using synchrotron radiation as the X-Ray source, the team was able to use X-Ray CT studies during the liquid metal dealloying process to reveal 3D bicontinuous structures that started to form on the outside of the structure on the initial formation of the molten materials. Over time, the average feature size within the material started to increase. The overall volume and volume loss remained relatively constant after a rapid increase at the beginning of the alloying process.

By having the 3D structural information and the capability of performing in-situ measurements, the team could divide the overall changes in the material into three steps; the initial dealloying, where the salt corrodes the metal-salt interface and leads to the dealloying that starts to spread throughout the structure. This is then followed by a coarsening step in which the average feature size continues to increase.

The team achieved this classification using image analysis software to visualize 2D virtual cross-section images and perform 3D morphology evolution. The use of automated image segmentation also helped to conclusively identify certain morphological features in the image and accurately quantify their morphological properties.

Conclusions

Advanced image analysis for the X-Ray CT was crucial for the identification and monitoring of structure growth. By understanding the morphology and formation mechanisms of bicontinuous structures in nanoporous metals using X-Ray nano-tomography during the dealloying process, the team hopes that there will be a greater uptake of less corrosive and more environmentally friendly methods of making these materials.

For this work, the research team made use of Avizo Software from Thermo Fisher Scientific. Avizo Software is an image visualization, processing, and analysis solution designed to help automate and streamline many image-processing tasks.

For complex image processing tasks that can be very time-consuming to perform manually, Avizo Software offers an intuitive and easy-to-use solution that can significantly accelerate standard tasks and allow researchers to focus on developing new generations of materials.

Learn more: Introduction to Avizo Software for metals and alloys characterization

References and Further Reading

- Duss, M., Salvati Manni, L., Moser, L., Handschin, S., Mezzenga, R., Jessen, H. J., & Landau, E. M. (2018). Lipidic Mesophases as Novel Nanoreactor Scaffolds for Organocatalysts: Heterogeneously Catalyzed Asymmetric Aldol Reactions in Confined Water. ACS Applied Materials and Interfaces, 10(5), 5114–5124. https://doi.org/10.1021/acsami.7b19740

- Allen, S. D., Bobbala, S., Karabin, N. B., & Scott, E. A. (2019). On the advancement of polymeric bicontinuous nanospheres toward biomedical applications. Nanoscale horizons, 4(2), 258-272. https://doi.org/10.1039/C8NH00300A

- Wen, W., Guan, S., Yang, Z., & Chen, A. (2021). Inverse Bicontinuous Structure by Polymerization-Induced Self-Assembly against Single-Chain Nanoparticles. ACS Macro Letters, 10(5), 603–608. https://doi.org/10.1021/acsmacrolett.1c00156

- Withers, P. J., Bouman, C., Carmignato, S., Cnudde, V., Grimaldi, D., Hagen, C. K., Maire, E., Manley, M., Du Plessis, A., & Stock, S. R. (2021). X-ray computed tomography. Nature Reviews Methods Primers, 1(1). https://doi.org/10.1038/s43586-021-00015-4

- Liu, X., Ronne, A., Yu, L. C., Liu, Y., Ge, M., Lin, C. H., Layne, B., Halstenberg, P., Maltsev, D. S., Ivanov, A. S., Antonelli, S., Dai, S., Lee, W. K., Mahurin, S. M., Frenkel, A. I., Wishart, J. F., Xiao, X., & Chen-Wiegart, Y. chen K. (2021). Formation of three-dimensional bicontinuous structures via molten salt dealloying studied in real-time by in situ synchrotron X-ray nano-tomography. Nature Communications, 12(1). https://doi.org/10.1038/s41467-021-23598-8

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific - Software.

For more information on this source, please visit Thermo Fisher Scientific - Software.