The electrification of passenger vehicles is predicted to achieve mass-market dominance by the mid-2030s.

Image Credit: Saint-Gobain

This will result from increasing environmental concerns, developments in battery technologies, and the implementation of stricter regulations regarding emissions. In addition, there will be government-issued incentives that help speed up the transition to cleaner alternatives for transportation.

Automotive manufacturers are under growing competition to provide faster charging, enhanced motor performance, greater capacity, and extended driving range.

However, high-powered electric batteries may experience thermal runaway. As the automotive industry evolves, the path ahead requires innovative cooling methods, smart battery safeguards, and game-changing materials that improve thermal safety.

Saint-Gobain® Tape Solutions offers various customizable thermal runaway propagation protection solutions. Such solutions assist with maintaining the balance between safety and innovation.

We are devoting our global expertise in materials, application, and manufacturing to tackle this critical issue of battery pack longevity and safety.

Fei Wang, R&D Manager for EV Platform, Saint-Gobain® Tape Solutions

Customizable Cushioning Pad for Battery Cells

Compression or tolerance pads are carefully designed to offset the dimensional variation of Li-ion batteries. They offer optimum cushioning support for the batteries and tolerate dimensional change during the battery breathing process.

This support includes the cell's reversible breathing (dimensional change) during its charge and discharge cycle and the gradual swelling throughout the battery lifespan.

Our concept of tunable intercell pads has helped us stay in the race when co-developing solutions with our EV customers for this extremely dynamic market.

Dominique Burgeff, Global Automotive Market Manager, Saint-Gobain

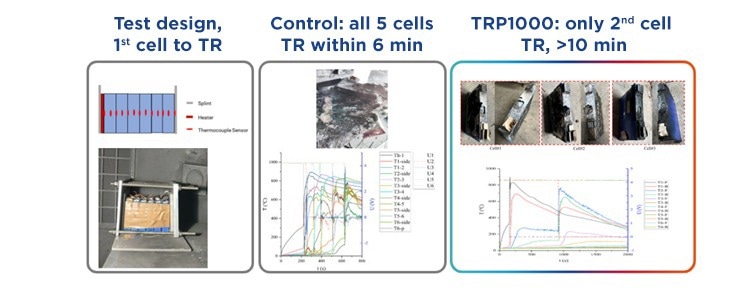

Saint-Gobain Tape Solutions can adapt its compression and tolerance foam to deliver various surface properties, such as adhesion, tackiness, supporting layers, and delivery format (e.g. stack or roll). This adaptability enables seamless integration into assembly lines.

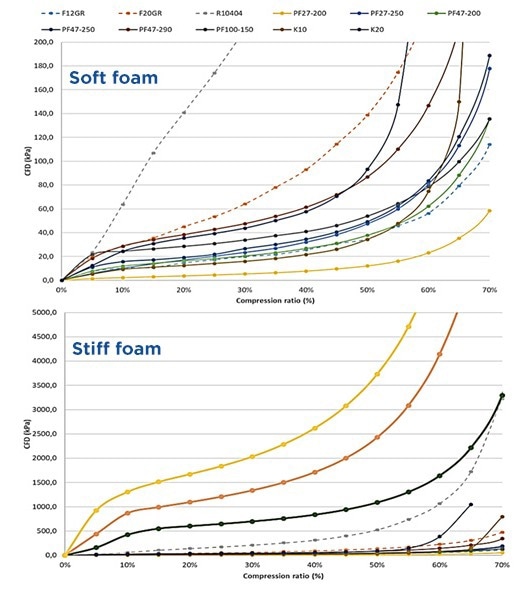

The company’s pads are adaptable to different battery types (pouch vs. prismatic) and materials (cathode, anode, or electrolyte). The tunable compression curves of these pads, together with the robust simulation capabilities, mean that Saint-Gobain can support specific customer needs and diverse battery configurations.

Figure 1. The range of compression curves Saint-Gobain Tape Solutions compression pads were able to reach, which meet the needs of different battery types (prismatic vs. pouch) as well as different materials including cathode, anode and electrolyte. Image Credit: Saint-Gobain

Exploring Diverse Levels of Thermal Insulation

Tape Solutions offers sophisticated simulation capabilities and agile material development to deliver products with various levels of thermal insulation and high-temperature integrity.

The company delivers different degrees of thermal insulation with products such as mica laminates with polyurethane (PU) foams, silicone foams, or V-0-rated silicone to guarantee that specific customer requirements are met.

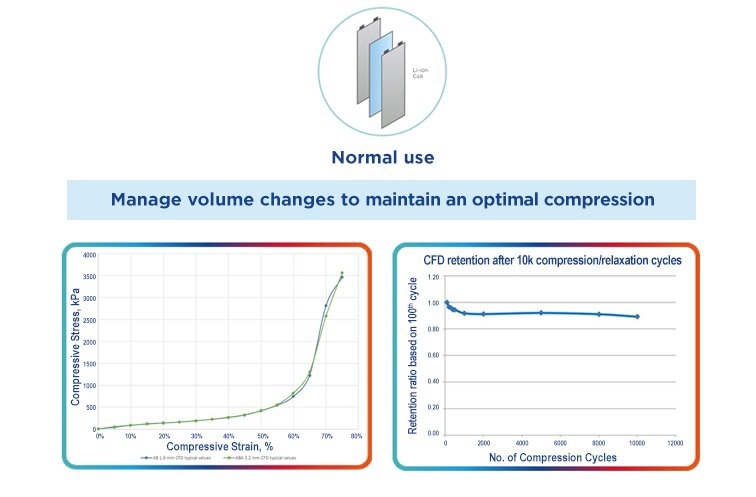

The upcoming Norseal® TRP1000 product is an example of this, with a proprietarily formulated silicone foam with mica surface layers. The flat compression curve of this product during normal usage means that the stress levels are maintained within a narrow range over a long range of compression strains.

The TRP product has properties that allow the properties of a compressible pad to be combined with thermal runaway protection.

Dielectric foams engineered with a predictable compression force deflection (CFD) replace vulnerable elastomer materials, delivering consistent return energy over various temperatures and compression amounts throughout battery pack life.

Due to its low compression set value, the foam resists permanent deformation under compressive loads, allowing greater protection on many fronts and minimal impact on energy density (Figure 2a).

Designed to keep battery cells under a specified range of protection, the Norseal TRP Series can serve as compression pads for prismatic hard-shell packs or pouch-cell packs.

As displayed in Figure 2b, the TRP insulation effectively mitigated the propagation of thermal events to neighboring cells during a thermal runaway test.

Figure 2a. Normal usage conditions of TRP1000 product featuring a flat compression curve over a long range of compression (left), the compression property is well kept over 10,000 compression cycles (right). Image Credit: Saint-Gobain

Figure 2b. When the first NMC622 battery went into thermal runaway from a heating plate initiation, 3 mm TRP insulation effectively prevented the other batteries in the module from thermal runaway. Image Credit: Saint-Gobain

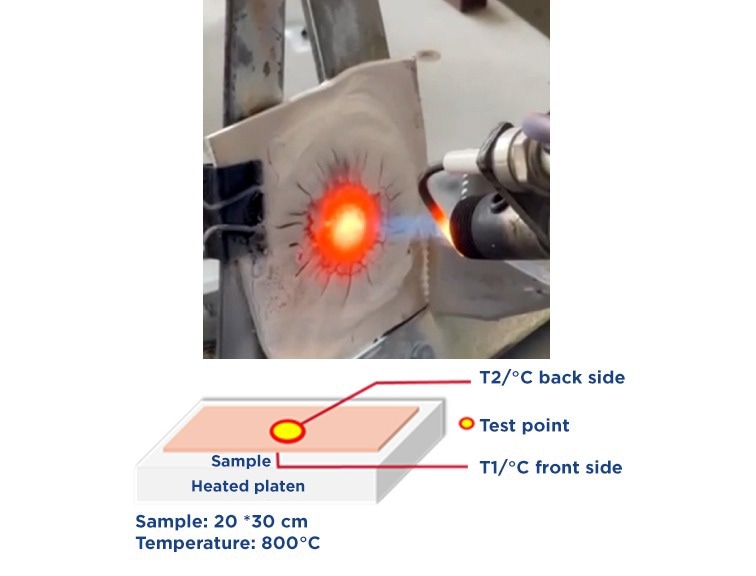

TRP1000 provides increased resistance to flame and temperature, in addition to improved durability for withstanding a thermal event. Early assessments of TRP1000 deliver impressive results, including:

- No self-ignition and measured temperature delta greater than 600 °C (1112 °F) when exposed to an 800 °C (1472 °F) hot plate for five minutes.

- The material integrity and insulation are maintained with a measured temperature delta greater than 600 °C (1112 °F) when exposed to a 1000 °C (1832 °F) direct torch for six minutes.

Regarding material development, Saint-Gobain Tape Solutions utilizes its global teams for strong material expertise, in addition to strong simulation and proxy testing capabilities to facilitate agile product development for its customers.

Scalable Design

The adaptability and customization of surface properties, such as adhesion, tackiness, and delivery format, is crucial to satisfy the demands of the manufacturing evolution.

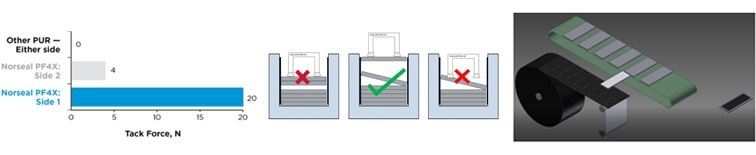

Guaranteeing that products hold specific surface characteristics can improve assembly processes due to properties like tacky surfaces or the capacity for vacuum pick-up processes. The ability to design to scale can deliver efficient automation.

Saint-Gobain’s polyurethane foam products (PU) have excellent compression and resilience, high conformability, and good cushioning, gap filling, and environmental resistance.

These products are offered with or without adhesive, making them well-suited for converting and improving die cuttability and spooling.

These foams are straightforward to apply and effectively minimize distortion or corrosion of dissimilar materials by removing any contact between materials. They also protect from environmental and mechanical stresses.

Figure 3. The surface tack of our PU foam could be adjusted to a desired level to attach to certain surface (such as battery case) to facilitate the assembly process (left picture); the surface roughness and tack can also be adjusted to meet required characteristics for enabling a customer’s vacuum pick-up process (middle picture, middle stack) while avoiding unnecessary blocking (left stack) or failure to be picked up (right stack); the pad can be either offered in stack format or in roll format (right picture). Image Credit: Saint-Gobain

Features such as custom finger-lifts, low liner release, and poke-yoke elements are vital for the successful operation of a work cell.

This is accomplished through our own Saint-Gobain adhesive experts and our growing expertise in conversion. Our conversion solutions are particularly valuable to our customers.

Thomas Veilleux, Technology Leader, Saint-Gobain Tape Solutions

Thermal Protection for Battery Pack, Battery Management Systems, Busbar and More

Saint-Gobain Tape Solutions offers a variety of products to provide thermal protection for the components within an EV, such as battery packs, battery management systems (BMS), and busbars.

The company aims to support special design needs (thickness, shape, thermal integrity, flexibility, and assembly process) by offering products that deliver high-temperature integrity as well as electrical and thermal insulation.

Key products and usages include the following:

- TRP-TT and TRP5000: Comprised of ceramifiable silicone rubber, these products are flexible at room temperature and offer ceramic insulation at elevated temperatures. They are well-suited for pack cover and busbar protection. These products provide an effective alternative to mica because of their low dust and high flexibility.

- CHR® FR1000 Tape: Tape comprised of a special mica substrate and a proprietary fire-resistant adhesive. This product offers a robust, thin gauge solution for improving thermal protection in specific areas, including solid surfaces, corners that require bending of a substrate, and design areas that have vulnerable holes.

The above products are subjected to extensive tests to guarantee their ability to withstand the most challenging conditions and demands. A 1000–1500 °C torch test and a UL94 test are among the most common tests performed by the team at Saint-Gobain Tape Solutions.

In addition to this, the company offers electrical insulation and mechanical tests or the addition of abrasive particulate options according to the requirements of the customer.

Figure 4. Typical set up of Flame torch test and Hot plate tests on TRP5000 (launching soon in North America and Europe). Image Credit: Saint-Gobain

Protection Solutions for Other Battery Pack Locations

In a thermal runaway event, products such as gaskets and seals, gap filler pads, or fixation tapes cannot be overlooked as vital solutions that also cater to the intricate demands of pack and module design, reinforcing safety and promoting reliability.

1. Gaskets and Seals

Saint-Gobain’s gaskets and seals provide various levels of protection for managing hot gases and heat dispersion. The flow and venting of these hot gases are crucial to keeping the rest of the battery pack intact. Some key products from the company include the following:

- ThermaCool® R10404 Series: This silicone sponge can withstand high temperatures (1000 °C torch) for prolonged periods of time. This makes them well-suited to applications where exposure to intense hot gases may take place.

- Norseal F-20 silicone foam: This product can form a hard structure after a fire event takes place, without becoming a powdery ash. This makes it ideal for applications where continued support of the pack structure may be required.

- Norseal PS-V0 Series: This is a UL-94-rated PU foam solution that delivers good fire resistance and cost efficiency.

- Norseal FS1000 Series: An intumescent PU foam solution that can expand multiple times and fill in a gap if a fire event should take place.

2. Thermal Interface Materials

Saint-Gobain offers thermally conductive gap fillers which act as a heat sink. These products provide a thermal path for heat to flow away from the battery. These materials' surface tack, hardness, and liner can be customized.

- ThermaCool TC2009 are gap filler pads that offer good thermal conductivity under normal usage conditions. These products have a specific formulation that facilitates good thermal insulation from the affected cell in a thermal runaway event.

3. Fixation Tapes

Pressure-sensitive adhesive tapes can be utilized for their versatility, strength, and functionality to overcome flammability issues or adhesion to various surfaces.

Saint-Gobain’s tape products with rubber, acrylic, or silicone-based technologies are effective for providing protection against thermal runaway. This is due to their good flame retardancy, such as VTM-0 or UL94 V-0, and their flexibility to work with all cell types.

Adhesive tapes offer support to thermal interface materials (TIMs) by helping battery cell or module cooling through bonding to heat sinks or chiller plate materials. The TIMs enable heat to be transferred between the components in EV battery assemblies.

In addition to this, flame retardant or dielectric tapes may be employed in applications (including electrical) that demand high flame resistance. Both single and double-coated tapes protect sensitive battery components within electrical insulation.

Rigid materials, such as aluminum chill plates and metal structures, are usually protected by single-coated tapes. However, double-coated tapes can offer electrical insulation to cell protection when used in combination with other materials, e.g. compression pads.

Saint-Gobain’s fixation tapes contain flame-retardant adhesives that enable certain parts to be attached while maintaining strong adhesion to various surfaces. These tapes offer good flame retardancy, such as VTM-0 or UL94 V-0.

Some of the company’s key products include EV145 double-sided adhesive tape, 80HS FR acrylic transfer adhesive tape, and customizable solutions with a range of options in tack, adhesion, liner, and thickness.

Next Steps in EV Advancements

The electrification of transportation is the future, and the implementation of EVs is quickly increasing. For continued success, battery technology advancements must continue to progress to support these newer modes of transportation.

Thermal management is critical to the safety of the battery, vehicle, and its passengers. Fortunately, automotive engineers have many options for securing thermal protection at optimal levels.

Saint-Gobain’s main objective is the continued research and development in thermal protection. The company’s teams have utilized strategies to balance the safety, lifespan, and performance of EVs, without compromise.

Saint-Gobain’s dedicated global teams have extensive experience in specialized product development. The company is a reliable partner for delivering products to satisfy the unique and demanding requirements to deliver total protection of EV battery packs. Contact Saint-Gobain Tape Solutions to discuss your specific requirements.

This information has been sourced, reviewed and adapted from materials provided by Saint-Gobain Tape Solutions.

For more information on this source, please visit Saint-Gobain Tape Solutions.