Sponsored by Mo-SciReviewed by Louis CastelJan 18 2024

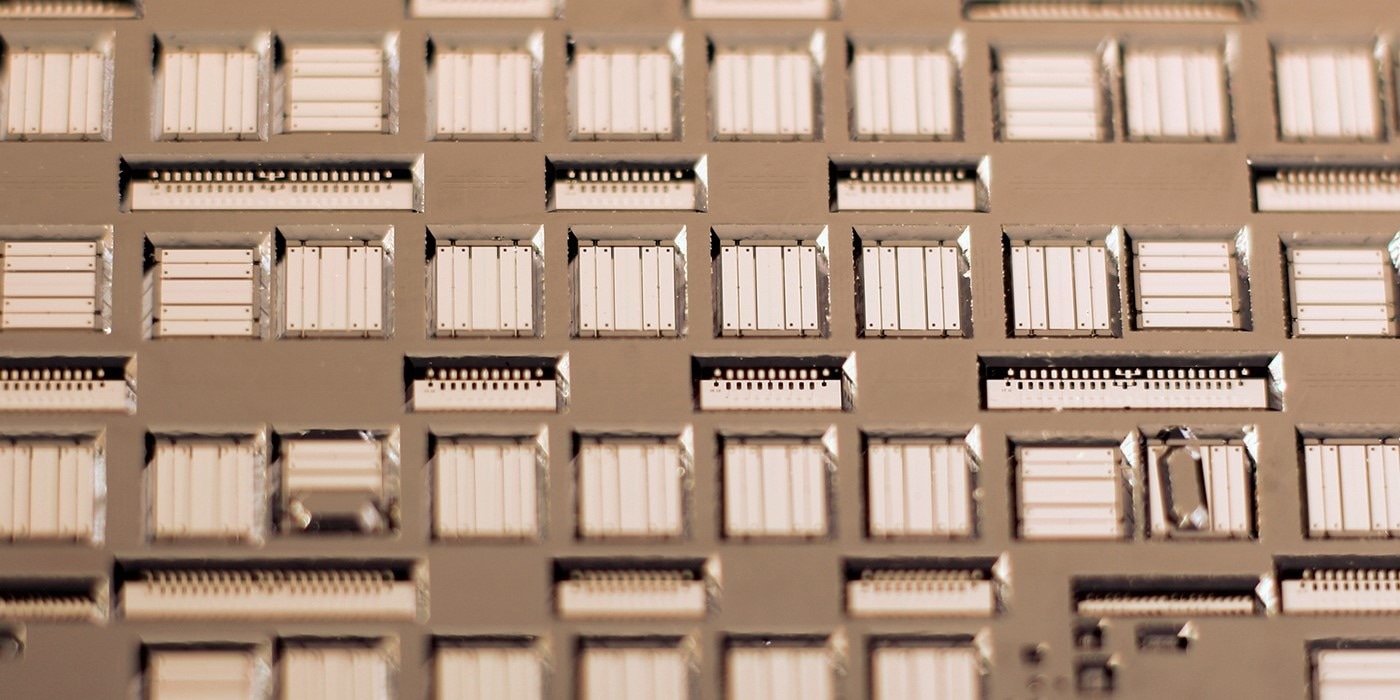

By integrating miniaturized mechanical and electrical components onto a single substrate, micro-electromechanical systems (MEMS) have transformed various industries, facilitating the construction of highly sensitive and efficient devices. MEMS are critical in various applications, including medicine, motorized vehicles, industry, and defense.1

The success of MEMS devices often relies on maintaining a hermetic environment to protect their delicate internal components. Glass sealing provides a superior solution for achieving reliable hermetic seals in precise applications such as MEMS manufacturing and packaging.2

Image Credit: iStock

Understanding the Importance of Hermetic Sealing

Hermetic sealing prevents the entry of moisture, contaminants, and other external elements by forming airtight barriers around devices. Even minuscule environmental influences in MEMS devices can alter performance or lead to failure. As MEMS are used in areas where constancy, precision, and reliability are vital, such as aerospace, medicine, and telecommunications, achieving a hermetic seal is vital.2

Glass Seals: An Ideal Solution for MEMS

Although various hermetic sealing techniques exist, glass sealing is a versatile and high-yield approach appropriate for MEMS applications.

The method utilizes the unique properties of glass to create a reliable, robust, and precise encapsulation for MEMS devices while imposing minimal stress on a bonding surface. In a three-step process, a glass paste is screen-printed on a capping wafer, which undergoes thermocompression bonding to the subject device for 10 minutes. This method applies 1000 mBar of force and 440 °C to the material under a vacuum.

This technique is capable of bonding hydrophobic and hydrophilic surfaces and can be applied to the most popular microsystem surface materials, such as aluminum, silicon, and glass.3, 4

Tailoring Precision Using the Coefficient of Thermal Expansion (CTE)

Glass seals precisely formulate glass compositions to match the coefficient of thermal expansion (CTE) of different materials.4 The CTE of a material refers to how the material changes alongside fluctuations in temperature. By tailoring the composition of the glass particles, the CTE can be adjusted to closely match that of the MEMS device and the encapsulating material. This compatibility ensures that, when subjected to variations in temperature, the seal remains intact without compromising the device’s structural integrity.2

Mo-Sci, a pioneering glass technology company, is a leader in developing and perfecting glass sealing solutions for various applications, including MEMS devices.

The company’s expertise lies in creating sealing glasses with customizable CTEs. Mo-Sci is an ideal partner for MEMS manufacturers seeking reliable hermetic sealing solutions, with a diverse range of glass–metal and glass–ceramic seals that are precisely matched in terms of CTE and capable of enduring temperatures up to 1600 °C. 2, 5

The Versatility of Glass Seals

The applications of glass seals extend beyond MEMS devices to a range of cutting-edge technologies.

Solar cells

Sealing glasses are useful in encapsulating perovskite photovoltaic elements. These elements are highly efficient and are cheaper alternatives to traditional silicon solar cells, but are highly sensitive to moisture, of which small amounts can completely inhibit function. Laser-assisted bonding of glass sealing ensures a durable hermetic barrier, shielding perovskite cells from moisture while locking in lead-containing chemicals.2

Metal ion and thermal batteries

Glass sealing has an essential role in enhancing the reliability and longevity of metal ion batteries in energy storage solutions, including lithium–ion and sodium–ion batteries, which require seals that can endure high temperatures and resist chemical corrosion. Glass seals provide a resilient barrier, enabling the efficient operation of advanced battery technologies.

They are also a practical solution for molten salt batteries, which are highly dependent on sodium salts (such as sodium–nickel, and sodium–sulfur chloride) to achieve notable energy and power densities, and which are therefore an appealing option for large-scale industrial and energy storage applications.

Hermetically sealed glasses are a high-energy alternative to conventional polymeric or metal seals, exhibiting excellent resilience against challenging chemical environments and the demanding operating temperatures inherent to molten salt batteries, which range from 300 °C to 350 °C.2

High-temperature sensors

Glass sealing also has applications in high-temperature settings, such as motorized vehicles and chemical processing plants. The corrosion-resistant and predictable thermal expansion and nature of sealing glass ensure the long-term stability of sensors operating in such environments.2

Solid oxide fuel cells (SOFCs)

Although their high operating temperatures present challenges, SOFCs hold remarkable promise for clean and efficient power generation. To create high-temperature sealant materials for SOFCs, Mo-Sci currently employs two methods, one of which relies on a traditional glass–ceramic seal wherein glass undergoes crystallization to establish bonds with the sealing components.

Mo-Sci’s second approach involves developing viscous-compliant glass seals, which remain vitreous throughout applications and can self-heal, mitigating the risks associated with thermal stresses and ensuring the longevity of SOFCs. This groundbreaking technology is expected to facilitate the commercialization and extensive adoption of SOFCs.2,6

The Future of Glass Sealing

Glass sealing technology has emerged as a promising solution for achieving hermetic seals in MEMS devices and other advanced functions. Companies such as Mo-Sci enable manufacturers to create highly reliable and robust encapsulation systems by precisely engineering the properties of sealing glasses.

As the horizons of technological innovation continue to broaden, the role of glass seals in preserving sensitive components and ensuring optimal performance becomes increasingly crucial.

References and Further Reading

- Lutz, M. (2021) Why Timing Must Be Tough Enough For Our Digital World [Online] Forbes. Available at: https://www.forbes.com/sites/forbestechcouncil/2021/09/02/why-timing-must-be-tough-enough-for-our-digital-world/ (Accessed on 10 August 2023).

- Grayson, K. (2021) Sealing Glass Applications [Online] Mo-Sci. Available at: https://mo-sci.com/sealing-glass-applications/ (Accessed on 10 August 2023).

- Chang, H-D., et al. (2010) High Hermetic Performance of Glass Frit for MEMS Package [Online] 2010 5th International Microsystems Packaging Assembly and Circuits Technology Conference. Available at: https://doi.org/10.1109/IMPACT.2010.5699539 (Accessed on 12 December 2023).

- Knechtel, R., (2015) Chapter 31 – Glass Frit Bonding [Online] Handbook of Silicon Based MEMS Materials and Technologies (Second Edition). Available at: https://doi.org/10.1016/B978-0-323-29965-7.00031-2 (Accessed on 12 December 2023).

- Grayson, K. (2020) Matching Coefficient of Thermal Expansion in Glass Seals [Online] Mo-Sci. Available at: https://mo-sci.com/matching-cte-in-glass-seals/ (Accessed 10 August 2023).

- Mo-Sci. [Online] Sealing Glass. Available at: https://mo-sci.com/products/sealing-glass/ (Accessed on 10 August 2023).

This information has been sourced, reviewed and adapted from materials provided by Mo-Sci.

For more information on this source, please visit Mo-Sci.