Coatings are not always just a protective layer, they can also be a critical enabler of performance, compliance, and sustainability. From improving energy efficiency and reducing manufacturing complexity to meeting stringent fire and corrosion standards, advanced coatings are reshaping how products are designed and maintained.

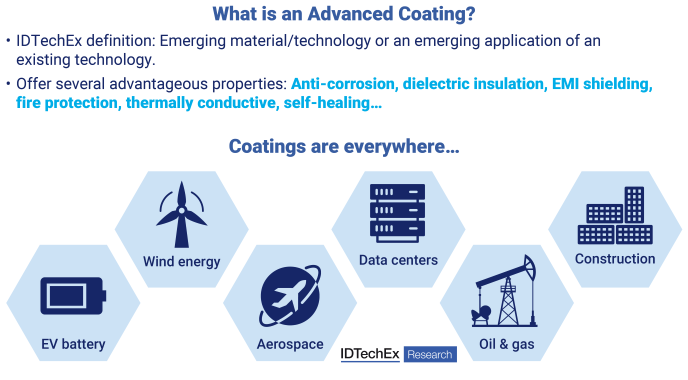

IDTechEx’s definition of advanced coatings and example markets. Image Credit: IDTechEx

IDTechEx’s definition of advanced coatings and example markets. Image Credit: IDTechEx

As electrification accelerates and global regulations tighten, coatings offer solutions that go beyond aesthetics, delivering functional benefits such as thermal management, electrical insulation, and environmental protection.

This transformation is happening against a backdrop of evolving legislation and sustainability goals, where coatings must adapt to meet requirements (both current and future) such as PFAS elimination, VOC reduction, and recyclability. These pressures are driving innovation in materials and application technologies, creating opportunities for manufacturers to gain a competitive edge. IDTechEx explores these trends in depth in its latest report, “Advanced Coatings 2026–2036: Market, Technologies, Players”, providing insights into market challenges, and the role coatings will play in enabling emerging solutions.

Advanced coatings can deliver a broad range of benefits that go beyond simple protection, enabling manufacturers to optimize performance, sustainability, and manufacturability. Ideally, these coatings should combine ease of application with robust functional properties. From a production standpoint, desirable traits include long shelf life to reduce waste, short ambient cure times for faster throughput, and minimal surface preparation to simplify processes and reduce costs.

One-component systems and low-viscosity formulations further streamline application, while water-based alternatives improve safety and environmental compliance. On the performance side, advanced coatings should be lighter and thinner to support compact designs but maintain strong substrate adhesion. High functional properties, such as dielectric strength, corrosion resistance, and thermal stability are critical for demanding environments.

Specific examples of how coatings can address critical challenges include both EV batteries and oil & gas infrastructure. In EV batteries, coatings help reduce production time and cost by replacing inorganic shielding with automated spraying processes, while dielectric insulation and fire protection to meet stringent safety standards like UL2596, whilst also supporting compliance with other evolving regulations.

In oil & gas, coatings combat corrosion under insulation caused by moisture ingress and harsh chemicals, extending equipment life and reducing costly downtime. Fire-resistant coatings that withstand extreme temperatures and corrosive environments further enhance safety for pipelines and process vessels. By enabling retrofitting and simplifying installation, advanced coatings deliver performance, regulatory compliance, and operational efficiency across these demanding sectors.

Sustainability and regulatory frameworks such as REACH are reshaping the coatings industry, both directly and indirectly. Direct restrictions, such as a potential ban on PFAS, could force reformulation of coatings to eliminate ‘forever chemicals,’ heavy metals, and VOCs. Indirect effects arise from compliance requirements such as recyclability and extended producer responsibility. Manufacturers increasingly incorporate recycled content and develop water-based, powder-based, and UV-curable systems to aid the meeting of evolving sustainability standards.

These changes not only reduce environmental hazards but also align with global sustainability goals. However, achieving compatibility with diverse regulations adds complexity, requiring coatings that maintain performance while meeting stringent safety criteria. As sustainability becomes increasingly essential, advanced coatings that combine PFAS-free formulations, VOC reduction, and recyclability will play a pivotal role in enabling efficiency, compliance, and innovation across industries.

There is a drive from manufacturers to develop formulations that go beyond current regulation, to future proof themselves from future targets which will most likely be more stringent.

Performance standards exert a significant influence on coating design, usually indirectly, as they encourage solutions that help products to meet stringent fire, corrosion, and energy efficiency regulations. Often performance standards need to be met for liability and insurance purposes. For fire protection, industries such as automotive and aerospace must comply with standards like FAR 25.853 in the US and CS 26.853 in Europe.

EV batteries face new rules such as China’s GB38031-2026, mandating no fire or explosion for two hours after thermal runaway and no visible smoke entering the passenger compartment within five minutes. Corrosion protection is described by ISO 12944. Energy efficiency directives, including the EU Energy Efficiency Directive and programs like DOE’s Better Plants, further push coatings to help to enable lighter, thinner, and more durable designs. These requirements often drive reformulation and innovation.

Coatings are a cornerstone technology across sectors, delivering solutions to challenges in EV batteries, oil & gas infrastructure, aerospace, data centers, construction, wind energy, and beyond. From enabling fire protection and dielectric insulation in complex battery architectures to combating corrosion under harsh chemical exposure in pipelines, coatings are driving compliance with evolving safety and sustainability standards. Their role extends further, supporting energy efficiency, recyclability, and reduced environmental impact.

As regulations tighten and performance demands rise, coatings will continue to unlock efficiency, durability, and innovation across global markets. For analysis of market trends, technologies and key players shaping this transformation, see IDTechEx’s latest report, “Advanced Coatings 2026–2036: Market, Technologies, Players”.