Plasma processes for electronics assembly produce improved adhesion and remove contaminants from electronic components. This article discusses examples of atmospheric argon plasma applications in electronic assembly.

Image Credit: Surfx Technologies, LLC

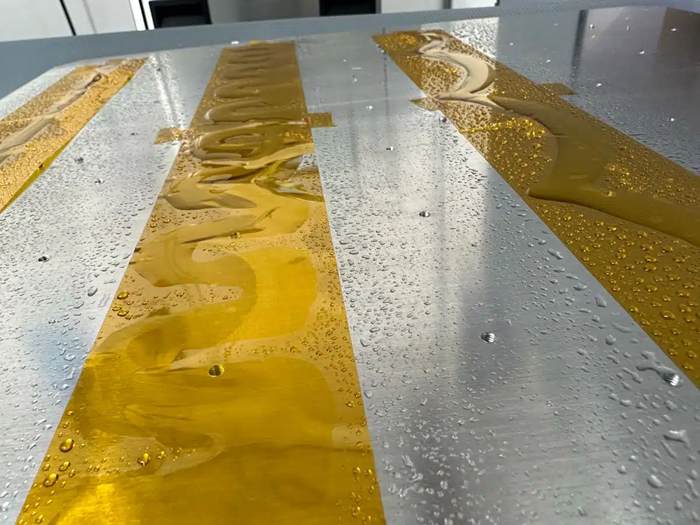

Wetting and Adhesion

For adhesives, coatings, and ink's to cover (wet) a surface, the surface energy of the adhesive must be less than that of the solid surface.

Many adhesives have a high surface energy and may, fail to wet and adhere to solid surfaces. Plasma can produce a target surface energy addressing these wetting issues, resulting in a more uniform coating and stronger adhesion to the surface

Solids with higher surface energy display enhanced adhesion and, in some cases, can bond with materials where previously impossible. By improving adhesion, manufacturers can use a wider range of coating materials and apply alternative coatings previously rejected due to difficulties with surface adhesion.

The cleanliness and wettability of a surface are vital. Before applying glue, ink, or coating, preparing component surfaces, circuit boards, and other electronic devices for wetting is crucial. Surfaces must be free from contaminants that may hinder the bonding process, such as release agents, monomers, oils, absorbed organics, and FOD.

Unlike conventional cleaning techniques, which may leave residues, plasma cleaning for electronics assembly prepares surfaces in a non contact method leaving no residue behind. The treatment can clean various surfaces, including FR4, ceramic, metals, plastics, glass, and composite materials, making it highly effective for electronics manufacturing, especially circuit board assemblies.

Conformal Coating

Conformal coating for electronics protects electronic components from environmental factors, including thermal shock, static, moisture, and vibration. Plasma cleaning is well known for improving adhesion, uniform coverage and eliminates voids. Plasma cleaning can eliminate orange peel, cracking, and delamination. These improvements prevent scrap and rework, yielding more profit for those who employ the technology. In addition, atmospheric plasma cleaning will increase the long term effectiveness of the conformal coating which results in more robust electronic assemblies for the real world.

Image Credit: Surfx Technologies, LLC

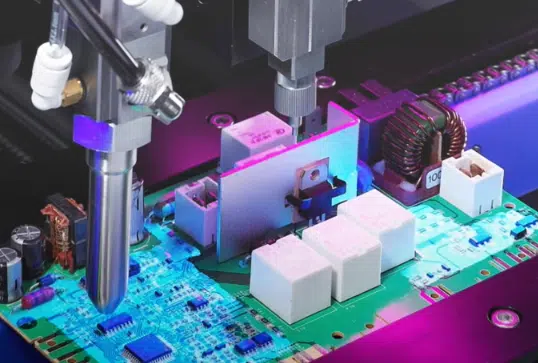

Plasma by Surfx Technologies

Surfx Technologies provides atmospheric plasma cleaning for electronics, with game changing weakly ionized argon plasmas without needing low-pressure chambers.

Surfx's atmospheric plasma facilitates in-line plasma cleaning, activation, and bonding enhancement by integrating plasma processes directly into manufacturing lines enabling single piece flow.

This new technology increases efficiency as parts need not be added to a batch process in vacuum for processing.

Surfx Technologies argon plasma is weakly ionized using hydrogen or oxygen radicals to clean surfaces, avoiding unwanted damage to sensitive components.

Surfx Technologies plasma increases clients’ profit by enhancing production efficiency and eliminating the risk of damage that can be caused by competing plasma technologies.

This information has been sourced, reviewed, and adapted from materials provided by Surfx Technologies, LLC.

For more information on this source, please visit Surfx Technologies, LLC.