Author: David Prieto, Application Specialist, Thermo Fisher Scientific

Industrial metal detectors are most often used to detect undesired metal contaminants that are unintentionally introduced into products at various stages of the manufacturing process in food and other industries.

Metal contaminants can arise from broken bits off mixing and molding devices during the manufacturing process, as well as personal things like hairpins and equipment gear like screws and bolts.

If foreign contaminants are not effectively discovered and eliminated prior to items reaching retail shelves, they may result in consumer complaints or, worse, consumer injuries and might permanently harm a brand's reputation overnight.

A typical industrial metal detector may detect metal signals and reject contaminated products or batches, avoiding costly rework or possibly a product recall. The capacity to identify metal in a product creates a new application for industrial metal detectors known as reverse detection.

The reverse detection capability is especially effective in applications where the presence of a metal or metallized component is critical to final product quality control. For these applications, instead of detecting and rejecting metal-containing products or packages, manufacturers want to ensure that metal-containing components are present.

This article will discuss the theory of regular metal detection versus reverse detection in industrial metal detectors and provide information on applications and operations.

Metal Detector Contaminant Detection and Reverse Detection

Modern industrial metal detectors are designed to be integrated into any manufacturing process.

Products move down a conveyor belt before passing through the metal detector's aperture. Metal detectors detect minuscule ferrous, nonferrous, and stainless-steel particles by winding coils on a nonmetallic frame and connecting them to a high-frequency transmitter.

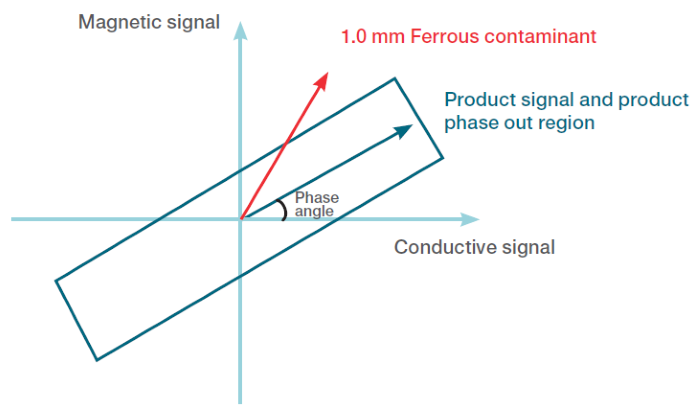

Figure 1. The principle of a metal detector when used for contaminant detection applications. Image Credit: Thermo Fisher Scientific – Production Process & Analytics

The transmitter coils are situated in the center of the detector housing (aperture), with several reception coils on either side of the transmitter coils in an equal number and spacing.

It should be emphasized that reverse detection is a software-enabled capability of industrial metal detectors, which means that no hardware modification is required to convert a metal detector used for contamination detection to a reverse detection application.

When a metal detector system is balanced, the signal received by the receiver coils on both sides of the transmitter coils is the same. As a metal item approaches one of the coils, the signal on that coil changes, and the difference between the two receiver coils is measured. This is when the metal presence is confirmed.

Image Credit: Thermo Fisher Scientific – Production Process & Analytics

A product learn function is typically provided in metal detector software to enable the creation of a baseline/threshold. In the case of contamination detection, a baseline is established by sending clean products free of metal contaminants through the metal detector.

A reverse detection application generates a baseline using products that include a metal or metallized component. In a reverse detection application, a pack of ramen noodles with flavor seasoning packed in a metallized film packet generates a significant signal when passed through a metal detector.

If a pack of ramen noodles without the flavor packet is passed through the metal detector, the signal will be significantly lower than the baseline, and the item will be rejected as required by the manufacturer.

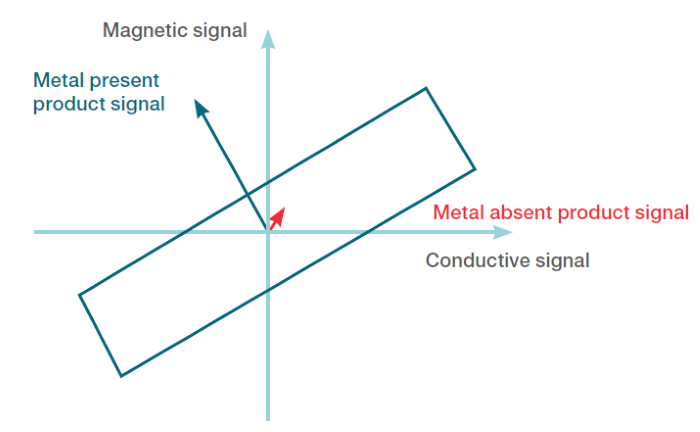

Figures 1 and 2 show a simplified version of the regular metal detector method and the reverse detection principle, respectively.

For contamination detection applications, a signal within the threshold (purple rectangle) is acceptable, whereas reverse detection applications require the opposite. If the product signal falls under the threshold (purple box), it indicates that the signal is too weak and there is little to no metal presence detected, hence it will be rejected.

Figure 2. Metal detector principle when used for reverse detection applications. Image Credit: Thermo Fisher Scientific – Production Process & Analytics

The screenshots below show the intuitive HMI from the Thermo Scientific Sentinel 5000 multi-frequency metal detector. In this case, the reverse detection feature has been enabled.

The detection threshold has been set at 36 dB for all five frequencies. A signal beyond this threshold is thought to be created by the presence of a metallized component, and it is highlighted in green.

A signal below this threshold is thought to be caused by the absence of a metallized component, and it is highlighted red. Figure 3 shows that the package will be approved if at least one frequency is green. The package will be rejected if signals at all frequencies fall below the threshold, as illustrated in Figure 4.

Figure 3. Screenshot of product with metal component present. Image Credit: Thermo Fisher Scientific – Production Process & Analytics

Figure 4. Screenshot of product with metal component absent. Image Credit: Thermo Fisher Scientific – Production Process & Analytics

Reverse Detection Applications

Metal is typically present in reverse detection applications as packaging material or small bits that are part of a multicomponent product or completed object. Some common applications that would benefit from reverse detection capability are:

- Ramen noodles with flavoring packets

- Baked goods mix with flavoring or icing packets

- A children’s meal kit that contains toys or stickers at a fast food restaurant

Image Credit: Thermo Fisher Scientific – Production Process & Analytics

The various ingredient packets found in ramen, muffin, and biscuit mixes typically use metallized film packaging, which is essentially a thin layer of aluminum deposited on polyester film to prevent moisture and oxygen from penetrating and changing the consistency and texture of the ingredient.

This small layer of aluminum, which can be nanometer-thin, will nonetheless produce a significant signal in the field of a metal detector.

Without the ingredient packets, the package signal will be solely derived from the dry noodles or flour in the mix, which generally produce little to no product signal in the presence of a metal detector's field.

This causes the whole package signal to fall below the reverse detection threshold, resulting in the product being rejected for rework or scrap. Children's meals at fast food restaurants sometimes include stickers or small toys.

To ensure that these components are included in every package, some manufacturers will choose a design with a small piece of metal built-in or use metallized film to package the toys, as well as stickers, so that the reverse detection metal detector can confirm their presence on the production line.

In addition to food uses, reverse detection can be useful in non-food product applications. For example, a nail polish producer may add a little metal ball to the nail polish bottle.

When consumers shake the bottle, the ball rolls around and stirs the nail paint, making it more uniform. Another example is residential power outlet cover plates, which typically have screws for easy installation.

Because all other components are plastic, utilizing a metal detector to check the presence of the screws is a critical step in the manufacturer's quality control process.

Many more applications could benefit from the usage of reverse detection technologies. When it comes to ensuring the presence of metal in a product or container, reverse detection should be seen as a top choice.

Important Notes on Reverse Detection

Various factors must be considered when using reverse detection to validate the presence of metal or metallized components in a finished product.

Reverse detection:

- Cannot be used simultaneously with contaminant detection

- Cannot be used when the final packaged product is also packaged with metallized film

- Requires sufficient pitch (distance) in between products as they pass through the aperture of the metal detector

Because of the huge signal provided by the metallized component within the final packaged product, minor foreign metal impurities may not be identified.

Suppose a manufacturer requires both contaminat metal detection and reverse detection on the same manufacturing line. In that case, it is advised that a second metal detector be put before the packaging line to inspect unpackaged products without interference from the metallized film.

The metal detector installed after packaging is exclusively responsible for establishing the presence of the metallized component. Similarly, when a metallized film is used as the product's packaging material, it may generate too much signal, overshadowing the little, metallized component within the product.

As a result, reverse detection after packaging is not recommended. If reverse detection is critical, it is preferable to install a metal detector before placing the products in the metallized film pouch.

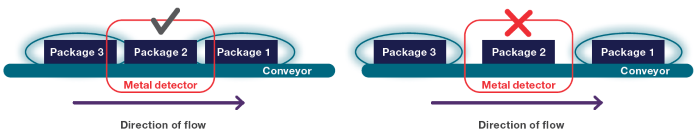

An adequate pitch (distance) between products is required for the signal from the previous package to completely diminish before the following product passes through the metal detector. Figure 5 shows how insufficient space between products might result in false acceptance.

Package one and Package three are good since they have a metal component, whereas product two does not.

Although Package two should be rejected, the metal detector compares the ripple signals from Package one and Package three and determines that Package two is an excellent product with a strong metal signal; thus, it is approved.

To avoid this issue, increase the space between the products on the conveyor. The exact distance required is determined by the metal component's signal strength, belt speed, product orientation, and size. Consult your metal detector manufacturer to find the optimal setting for your unique application.

Figure 5. Illustration of how insufficient distance between packages can cause false acceptance. Image Credit: Thermo Fisher Scientific – Production Process & Analytics

Conclusion

Reverse detection is a well-established yet underutilized capability of industrial metal detectors. It is useful for various applications that require confirmation of the presence of metal or metallized components.

This skill demonstrates how metal detectors may be an essential element of a manufacturer's quality control program, saving on costly product rework time and assuring consistent high-quality products for their consumers.

This information has been sourced, reviewed, and adapted from materials provided by Thermo Fisher Scientific – Production Process & Analytics.

For more information on this source, please visit Thermo Fisher Scientific – Production Process & Analytics.