AZoM speaks with Paul Senior of Hiden Isochema about how dynamic vapor sorption (DVS) technologies are advancing to support the growing demands of modern materials research, from sustainable polymers to complex porous frameworks, and the innovations driving the future of sorption analysis.

Can you introduce yourself, your experience so far, and your role within Hiden Isochema?

I am currently a Product Manager at Hiden Isochema, where I lead strategy and development for our benchtop Dynamic Vapor Sorption (DVS) systems, including the IGAsorp and the new IGA ECOsorp. I joined the team in 2025 during an exciting time of growth and innovation for the company.

My background spans over a decade in physical characterization instrumentation - starting as a user in the pharmaceutical industry, working with technologies like particle size and shape analysis, and gas sorption. That experience naturally evolved into R&D roles, where I helped develop next-generation particle characterization instruments, and later into product management.

At Hiden Isochema, my role is wonderfully varied. I collaborate closely with marketing and sales teams, and I am a key stakeholder in shaping the direction of future product development.

What I am most passionate about is product development itself, particularly the opportunity to engage directly with users across industries. Understanding their challenges, their “problems to solve,” is what drives innovation. It’s about exploring how a reimagined DVS technique might help them work smarter, faster, and more accurately.

This user insight feeds directly into our R&D efforts, where we’re looking to push the boundaries of vapor sorption technologies. It’s a role that gives me a unique vantage point - not just on where DVS stands today, but on where it’s headed. And that future is something I am genuinely excited to help shape.

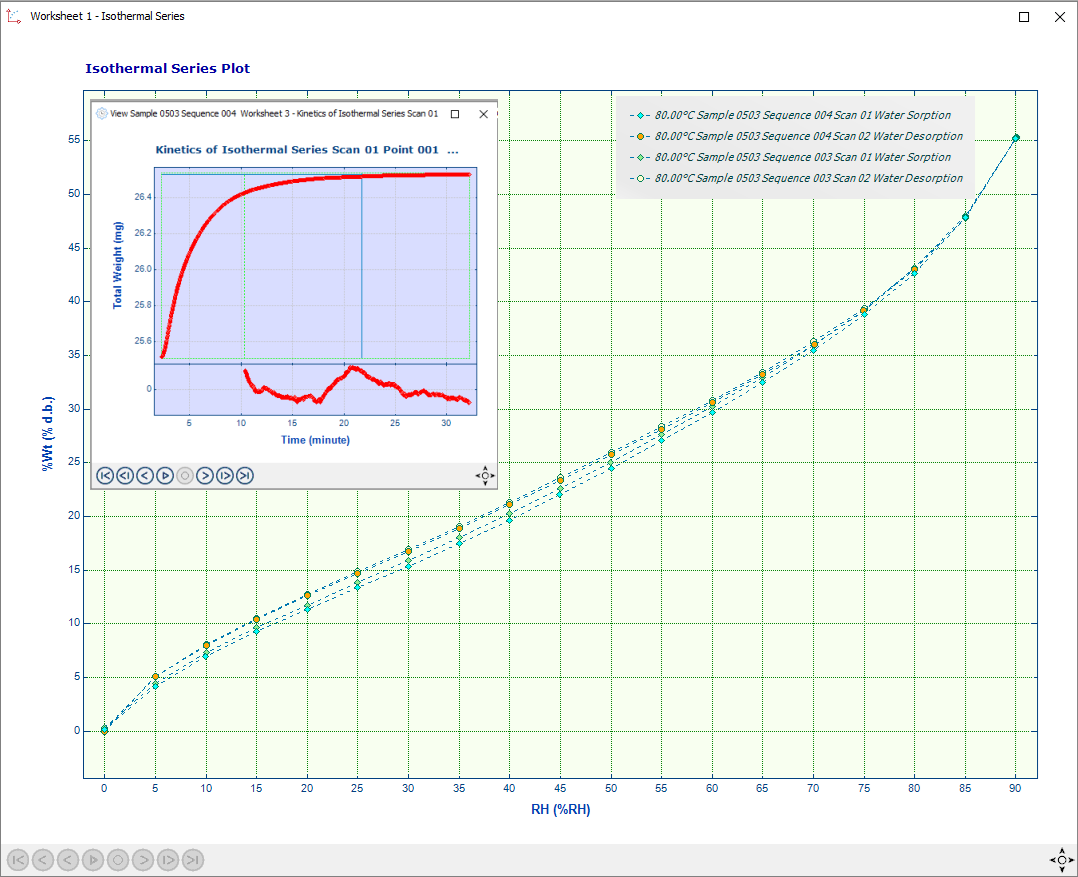

Image Credit: Hiden Isochema

How has Hiden Isochema’s approach to dynamic vapor sorption evolved over the years?

Hiden Isochema’s dynamic vapor sorption solutions have continually advanced with a steady cadence of customer-focused innovation, tracking with changes in technology and application needs.

Reliability and performance have always been fundamental to our instruments. These systems are built to last, with many still operational in the field decades after installation, which speaks volumes about their engineering and long-term value.

And since its launch in the late 1990s, the IGAsorp has undergone regular, incremental improvements rather than the occasional overhaul.

I think this agile development model has helped us to keep up with both technology advances and evolving industry requirements. For example, we have continued to refine the software capabilities, improved environmental control, and introduced accessories like a color video microscope and Payne cell for vapor transmission rate determination. In 2024, we even introduced a specific system, the IGA ECOsorp, to meet the needs of carbon capture research.

One particularly impactful change we made was bringing microbalance manufacturing in-house. This shift allowed us to tighten quality control, improve measurement precision, and ensure that every IGAsorp delivers best-in-class baseline stability and resolution. It’s advances like this that will really lay the groundwork for our next phase of DVS evolution.

What do you see as the next major innovation in DVS hardware, and how is Hiden Isochema preparing for it?

The future direction for DVS hardware will likely center around flexibility, integration, and expanded application versatility. As user workflows become more diverse and demanding, the hardware will need to adapt accordingly. And I think that will involve modular hardware designs that can be tailored to specific research or production environments.

With respect to application versatility, there will be more interest in being able to handle more extreme conditions of temperature, humidity, and sorbate species compatibility.

Another possible frontier is orthogonality; that is, pairing DVS with other complementary techniques, as has already been done with microscopy, Raman spectroscopy, and mass spectrometry hyphenation on the IGAsorp.

At Hiden Isochema, we’re preparing for this future by staying agile in our development approach, investing in technologies that support adaptability, and most importantly, listening to our customers.

How is software development influencing the way users interact with and analyze DVS data?

Software development is absolutely shaping how users interact with and analyse DVS data. But it’s not a case of software evolving and users needing to catch up. In fact, it is the opposite. What we are seeing is a shift in user expectations: researchers, analysts, and QC teams want to engage with DVS data in ways that suit them. And that is a shift we’ve embraced in the development of Hiden Isochema’s HIsorp platform.

HIsorp has grown into a flexible, scalable software environment that empowers users to interact with our DVS systems on their own terms. For QC users, that might mean running sequences with minimal intervention and with simple data analysis options immediately available. On the R&D side, the needs are often more complex with researchers wanting the freedom to design and execute bespoke, multistage experimental sequences with advanced data analysis option. HIsorp supports it all, with system control and analysis integrated into a single software suite.

What’s exciting is that this flexibility not only accommodates different user types but also actively encourages innovation. And as we look ahead, I think this user-led approach to software development will continue to play a significant role.

Image Credit: Hiden Isochema

Can you share how your IGAsorp series is being used in emerging application areas?

The IGAsorp is supporting researchers across a range of emerging applications, from sustainable and bio-based innovations to advanced porous systems. These different areas all require precise sorption analysis to inform both material performance and design.

In sustainability research, IGAsorp is being used to assess moisture sensitivity and degradation in eco-friendly polymers and bioplastics. Researchers have conducted stability tests under varying humidity and temperature conditions to simulate accelerated aging and weathering, allowing for comparisons using DVS data linked to mechanical properties, such as tensile strength.

In biomedical applications, IGAsorp is supporting the characterization of biomaterials such as chitosan-based nanofibers, which are of interest in tissue engineering. By quantifying water vapor adsorption and desorption under controlled humidity, researchers are starting to understand scaffold stability and long-term performance in physiological environments. This is particularly relevant as the field moves towards 3D bioprinting and personalized medicine.

And, in the area of porous materials, IGAsorp and IGA ECOsorp are helping researchers explore the water vapor stability of Metal Organic Frameworks (MOFs) and Covalent Organic Frameworks (COFs), materials now at the forefront of material engineering following the 2025 Nobel Prize for Chemistry.

These materials have very high internal surface areas and customizable chemistry, which makes them ideal for applications such as gas storage, separation and sensing. For example, researchers are using DVS to assess how modifications of properties like pore size and functionalization will affect sorption behavior and stability.

What trends are you seeing among your customers in fields like pharmaceuticals, food science, or energy materials?

We are seeing a clear evolution in how customers approach vapor sorption analysis across these different industries. There is certainly a growing emphasis on precision and real-world relevance, but with speed and simplicity as the default.

Users are asking more of their systems than ever before, and rightly so. The stakes are high, whether it's regulatory approval, shelf-life prediction, or optimizing energy efficiency, and DVS is increasingly important to delivering the right data at the right time.

Across all these sectors, there is also a clear trend towards users wanting more expansive data sets - higher-resolution isotherms and increased interest in kinetics data, for example. And there is increasing use of DVS data in predictive modeling.

Image Credit: abdullah mubarak achmad/Shutterstock.com

Where do you see the biggest opportunity for DVS in materials characterization over the next five years?

Over the next five years, I see a significant opportunity for DVS in being transformed from a niche tool to a more mainstream necessity across materials characterisation. The value to many industries is already clear, but the key challenge lies in making the data more actionable.

Users need data that is not just accurate, but immediately usable for their decision-making, whether that is predicting stability and risk profiles of pharmaceutical formulations or determining how milk powders will flow during processing ahead of chocolate manufacture.

Advancements in throughput will allow more data to be generated more easily. Advancing microbalance and environment control technology will allow even more precise and accurate sorption data to be generated, and developments in software will allow the integrity and quality of that data to be tracked automatically, so users can be completely confident of that data. Crucially, seamless data export will allow DVS results to feed directly into predictive models and AI-driven platforms.

In short, the opportunity is to make DVS data not only available but also indispensable.

What sets Hiden Isochema apart as a leader in this space, particularly as demand for high-precision vapor sorption data grows?

What really sets Hiden Isochema apart is our expertise across the full spectrum of gas and vapor sorption - not just DVS. Our portfolio spans pressure, temperature, and vacuum-based systems, and we are comfortable working in complex environments. As DVS requirements grow more demanding, we are well-positioned to innovate and support users with tailored, high-precision solutions.

We are also strong advocates for best practice in sorption analysis. Our IGA method for endpoint determination is a great example of this, as it is designed to deliver higher-quality data with faster analysis times.

We also actively contribute to interlaboratory studies, including recent work on water vapor sorption in wood samples, helping to refine methodologies and drive broader adoption of robust DVS systems. Finally, our involvement in international standards groups further reflects our commitment to advancing the field.

And beyond the technology, we offer exceptional training and lifetime support for every system we ship. Irrespective of the age, we will work to ensure it continues to perform at its best. That long-term partnership is a key part of what makes us a trusted leader in vapor sorption.

Hiden Isochema - an introduction

Want to know more? Get in touch with an expert

About the Speaker

Paul Senior is a product leader in analytical instrumentation, currently driving innovation as Product Manager at Hiden Isochema. With over a decade of experience in material characterisation, his career spans contract research, instrument development, and product management. Paul’s technical expertise lies in rheology, particle characterisation, and sorption science - fields where he sees data not just as output, but as insight with global impact. His core motivation is transforming scientific understanding into actionable strategy and compelling narratives that shape market direction and inspire customer confidence.

This information has been sourced, reviewed and adapted from materials provided by Hiden Isochema.

For more information on this source, please visit Hiden Isochema.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.