Many R&D leaders who embark on a digital transformation path confront a common dilemma: should they install an Electronic Lab Notebook (ELN), a Laboratory Information Management System (LIMS), or a Materials Informatics platform, and in what order?

With over a decade of experience in assisting hundreds of companies with these challenges, Citrine Informatics has created this guide to highlight the distinctions and offer a value-maximizing strategy.

Understanding the Three Core Technologies

- Electronic Lab Notebook (ELN): The Electronic Lab Notebook (ELN) is a computerized counterpart of the classic lab notebook that scientists use to record experiments, observations, and notes. ELNs are excellent at gathering unstructured research material and encouraging collaboration via customized procedures and searchable documentation.

- Laboratory Information Management System (LIMS): The Laboratory Information Management System (LIMS) is a sample-centric and process-centric system for managing structured laboratory activities. LIMS facilitates the tracking of samples and metadata, the management of workflows and instrument data, the enforcement of standard operating procedures, and the routing of data for reporting purposes.

- Materials Informatics: Materials Informatics combines AI, machine learning, and materials knowledge to speed up material and chemical discovery, development, and optimization. Extends beyond storage to use data for forecasts and insights.

The Core Value Proposition

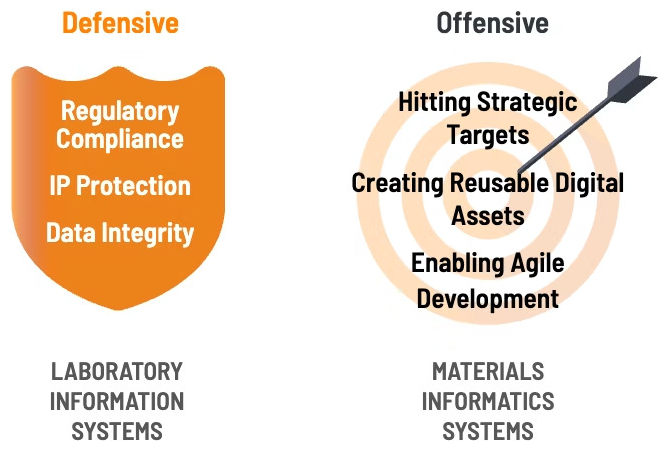

ELN/LIMS: Data Management Focus

The primary purpose of ELN/LIMS technologies is to manage, organize, and store experimental data in a systematic manner. They improve.

- Ensuring data integrity and traceability

- Encouraging collaboration in labs

- Providing access to shared records

- Preventing data loss

Materials Informatics: Data Utilization Focus

Materials Informatics platforms do more than store data; they use data to identify trends and make predictions. Their goal is to generate better, cheaper, and greener products more quickly by using AI/ML to identify viable tests and formulas.

According to studies, using AI in materials research and development can cut the number of trials required by 50-80 %, significantly speeding up development cycles.

Image Credit: Citrine Informatics

Strategy 1: The "All-In-One" Solution

Some companies contemplate an "all-in-one" platform that claims to manage ELN, LIMS, and AI/ML all in one place. While this sounds great on paper, it often falls short in practice.

- A Reality Check: Developing a best-in-class materials AI platform is a massive undertaking. Many traditional lab software companies have only recently started incorporating "AI/ML capabilities"; it is implausible for them to have attained cutting-edge performance so rapidly.

- Common Disappointments: Citrine Informatics’ team met with dozens of R&D leaders who tried the all-in-one approach and were unhappy. The integrated solution frequently performs poorly in multiple areas rather than excelling in any of them.

Common Issues with All-In-One Solutions

- Requires Too Much Data: Generic AI/ML models may lack domain-specific intelligence, necessitating excessive data collection. They require massive volumes of data to identify important patterns, making them unsuitable for materials science, where experimental data might be scarce and expensive to get.

- No Inverse Design Capability: Traditional "all-in-one" tools lack inverse design capability, instead focusing on predictive modeling (e.g., forecasting attributes based on composition). They lack inverse design capabilities, which means they cannot prescribe how to attain desired material attributes or propose new formulations based on goal performance requirements.

- Not Chemically Aware: General-purpose AI platforms often lack understanding of chemical structures, bonding, reactions, and material characteristics. This substantially limits their capacity to provide useful insights or chemically sound recommendations for novel materials.

- Limited Constraint Handling: Real-world materials development faces various constraints, including cost, manufacturability, safety standards, and raw material availability. All-in-one solutions frequently struggle to incorporate these complicated, real-world restrictions into their models, resulting in unrealistic or unworkable suggestions.

Strategy 2: ELN/LIMS First, Then AI

Another popular technique is to construct an ELN/LIMS system first, then overlay AI/Materials Informatics later. Many organizations believe that all data must be carefully organized before beginning AI work.

- The Garage Analogy: Imagine creating a big garage to keep costly cars without knowing where it will end up or what it will be used for. You spend years building it only to discover it is in the wrong location, gorgeous but useless.

- The Reality: Companies spend one to two years deploying ELN/LIMS, expending considerable resources, just to have everyone ask, "Remind me why we are doing this?". Scientists become demotivated when they do not find a clear value.

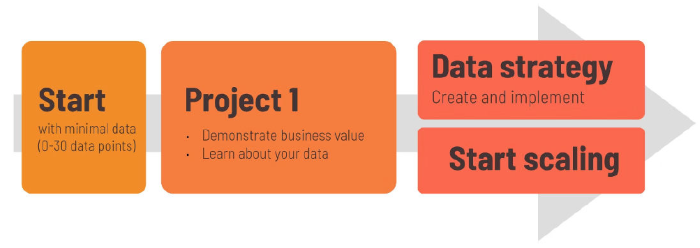

- The Better Way: Less data is required to derive value from AI, unlike popular belief. Instead than attempting to organize everything at once, start small, demonstrate value, and learn what is truly required.

Why the Sequential Approach Often Backfires?

- The Misconception: The premise that AI/ML requires precise data organization is erroneous. Successful materials informatics projects have started with as few as 32 data points.

- The Agile Alternative: Begin an AI pilot with existing data, even if it is chaotic or incomplete. Iteratively upgrade your data infrastructure based on that experience rather than theoretical requirements.

Implementing ELN/LIMS as a precondition for AI can drastically slow or derail your AI project. It is like laying the perfect foundation but running out of money to build the main structure.

Strategy 3: Materials Informatics First (Recommended)

The most effective technique is to begin with a Materials Informatics platform and then decide on ELN/LIMS requirements later. Lead with the instrument that will directly expedite research and development.

- Faster Time to Value: Materials informatics platforms may provide insights in months, not years. Meaningful outcomes are often achieved in a fraction of the time that a comprehensive ELN/LIMS implementation would require.

- Lower Upfront Effort: Starting Implementing AI does not necessitate a massive investment. Often starts with simple datasets from Excel sheets or database outputs via basic CSV uploads.

- Tangible Results: Measurable outcomes such as new product versions, cost reductions, or 50 % fewer experiments required to achieve desired performance.

- Smarter Subsequent Choices: Implementing AI helps assess data infrastructure demands, avoiding costly mistakes and over-engineering.

Image Credit: Citrine Informatics

The AI-First Advantage

- Immediate Impact: Generate compelling success stories like "our AI model helped us create a 20 % stronger material in half the development time" to build momentum and justify more investment.

- Positive Feedback Loop: Success inspires improved data practices. Scientists are more willing to enter and retain data when they perceive it as producing advances.

- Focused Infrastructure: Clients may find that using AI platforms reduces the need for a separate ELN/LIMS, resulting in a more manageable scope.

This "AI-first" technique reverses the typical script of "organize everything, then optimize" to "optimize now, then organize what proves useful."

Making the Right Choice for Your Organization

There is no one-size-fits-all solution because each R&D organization has distinct needs and limits. However, do not allow conventional wisdom to hold back the practical benefits that AI-driven materials development can provide.

Key Principle

Digital transformation in R&D should be outcome-driven. Organizing data is a means to a purpose, not an end in itself. Keep the end goal in mind: better products created faster and more sustainably.

The Citrine Advantage

With over 12 years of experience in materials informatics and a team of experts in chemistry, materials science, AI, and change management, Citrine Informatics can help you create a roadmap that is tailored to your needs and maximizes value at every stage.

Prioritizing the ability to learn from your data allows your organization to make better decisions about everything else. Citrine hopes to create better, greener, and more inventive materials in a way that empowers your R&D team.

This information has been sourced, reviewed, and adapted from materials provided by Citrine Informatics.

For more information on this source, please visit Citrine Informatics.