Sponsored by XradiaApr 22 2013

Carbonates are considered to have most of the remaining hydrocarbon reserves. They are the key rock type for oil and gas research as well as in climate engineering, especially for carbon sequestration initiatives. In both fields of study, the carbonate pore structure characterization plays a decisive role.

For digital rock analysis, Xradia offers a multi-length scale X-ray microscopy (XRM) solution that can capture images at multiple resolutions from micrometer scale to nanometer scale, which is especially essential for complex sandstones and heterogeneous carbonates.

Significance of Carbonate Rock Analysis

In the oil and gas industry, knowledge on the hydrocarbon-containing pore networks will be helpful in the estimation of reservoir potential and in the optimization of the recovery methods. For carbon capture and sequestration studies, the injection of carbon dioxide into carbonate reservoirs is a potential solution to alleviate global warming. For this purpose, it is essential to know the storage properties of the carbonate pore networks.

Challenges in Carbonate Rock Analysis

It is not easy to characterize carbonate pore structure because of the high heterogeneous nature of the rock, with large macro-scale vuggy pores to tens of nanometer scale pores. Digital rock analysis of carbonates is rapidly becoming recognized as a complementary method to traditional core and core plug analysis. This technique simulates the physics of flow through high-resolution virtual depiction of rock pore networks to acquire knowledge about the dynamics of single- or multi-phase flow. This, in turn, provides the data on the efficacy of potential reservoir recovery techniques. However, existing imaging techniques have their own limitations. Large-scale (industrial) X-ray CT systems need the resolution for detection of anything beyond very large vuggy pores, while3D electron microscopy techniques, although, provide high resolution, they take more time and are extremely limited by field of view for statistically significant 3D measurement of medium- to large-scale pores.

Solution from Xradia

A multi-length scale solution is needed to tackle the wide distribution of pore sizes. Latest developments in 3D XRM methods provide many different resolutions and field of view setups that facilitate carbonaceous rock analyses with a spatial resolution of up to 50 nm. Xradia offers a multi-length scale XRM solution for digital analyses of carbonaceous rocks. The solution consists of VersaXRM (<0.7 µm spatial) and UltraXRM (50 nm spatial) 3D microscopes that can capture images at multiple resolutions from micrometer scale to nanometer scale, which is essential for complex sandstones and heterogeneous carbonates.

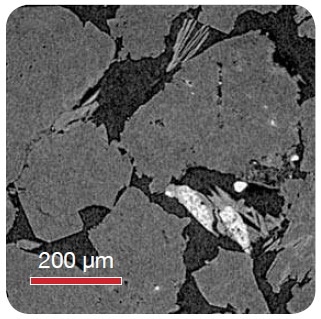

Figure 1. Sandstone - High resolution sub-area imaging to resolve clay from pore structure with VersaXRM at a resolution of 0.95 µm voxel size

An automated rotating detector turret in the VersaXRM allows for the Scout-and-Zoom imaging workflow, to survey regions of interest at a large field of view (LFOV) in order to identify statistical relevance prior to performing in-depth high resolution scans, all devoid of physically cutting down the sample.

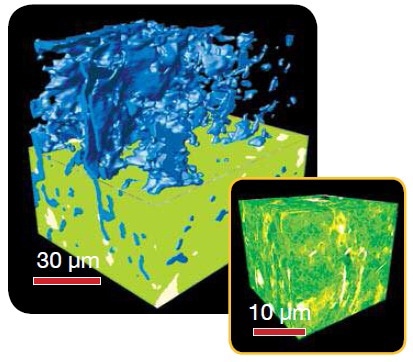

Figure 2. Shale Submicron pores: VersaXRM Resolution: 0.29 μm

It is possible to extend the scope of this multi-length scale analysis through the combination of the VersaXRM and an UltraXRM, which can be utilized to identify sampling locations for EM imaging. In this manner, X-ray microscopy provides an analysis continuum and closes the gap between industrial CT and electron microscopy.

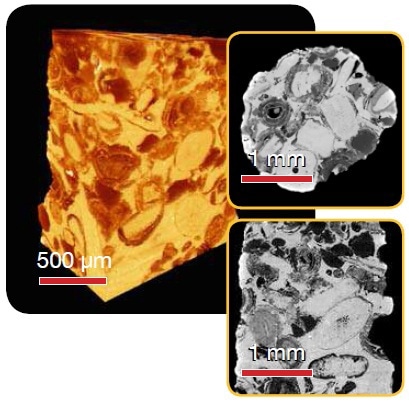

Figure 3. Calcite - Superior contrast and resolution in 3D and virtual internal slices with VersaXRM at a resolution of 1.4 µm voxel

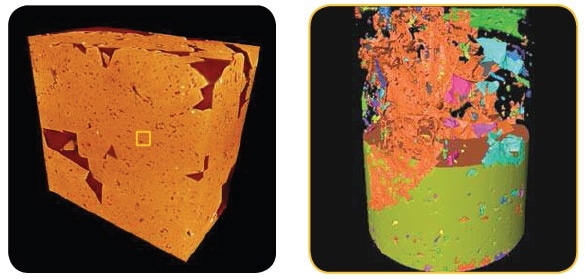

Researchers are now able to gain key insight for tight pore network measurement through the use of multi-length scale X-ray microscopy for carbonate analysis. A carbonaceous rock sample imaged at both the VersaXRM and UltraXRM length scales is shown in Figure 4, depicting the virtual segmentation of rock sample into its constituent phases at both the VersaXRM and UltraXRM length scales. This, in turn, allows for isolation of the porosity.

Figure 4. A carbonate rock sample imaged on the VersaXRM-500 with 360 nm voxel size (left) and UltraXRM-L200 with 65 nm voxel size (right). In the UltraXRM result, the solid phase is rendered with a green color (bottom) and is partially stripped away to reveal the pore network (top). The pores are further labeled by connectivity, with the largest connected pore labeled by a rust color.

These results may be utilized for the analysis of parameters as shown in Table 1.

Table 1. Figure 4 Results

| Summary of pore analysis |

| Porosity |

7.68% |

| Connectivity |

73.52% |

| Tortuosity (average) |

3.79 |

| Tortuosity (largest connected) |

3.55 |

These results may be coupled with computational fluid dynamics modeling software in order to gain insight into key rock characteristics such as absolute and relative permeabilities.

Conclusion

X-ray microscopy is a robust instrument to perform multi-length scale carbonaceous rock analyses. The combination of VersaXRM and UltraXRM provides a unique insight at length scales to acquire key data missing from traditional CT and EM imaging. The non-destructive approach of this method is widening the scope of carbonaceous material studies to assess the feasibility of oil extraction through the use of the novel Scout-and-Zoom architecture, which ensures the characterization of features and pores across the length scales.

This information has been sourced, reviewed and adapted from materials provided by Xradia.

For more information on this source, please visit Xradia.