Surface Measurement Systems invented the world’s first Dynamic Vapor Sorption Analyzer in 1992.

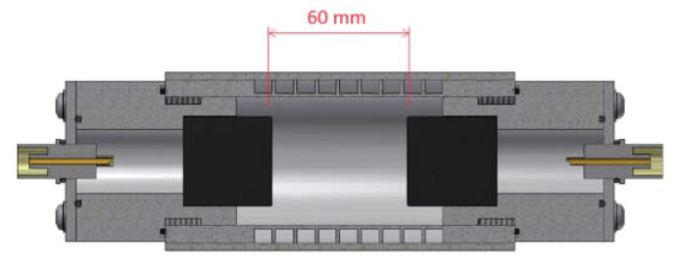

The DVS Resolution is the result of about 25 years of world leading innovation in gravimetric instrumentation. The new DVS Resolution is a water vapor sorption analyzer designed to measure sorption and desorption isotherms over a wide range of humidities and temperatures (5-85 °C 0-98% RH).

The DVS Resolution provides unparalleled humidity performance and temperature stability as well as a range of optional modular attributes. It offers crucial information regarding the interactions of a sample with water vapor that is essential for the development of new processes and materials. A number of industries consider water sorption properties of raw materials as key parameters in establishing their storage, processing, stability and application performance.

Key Measurement Capabilities

- Water, organic solvent and gas sorption and desorption isotherms

- Sample masses from 1 mg to 5000 mg

- Co-adsorption isotherms using two vapors

- Multiple sorption/desorption and sample drying or activation cycles

- Surface and bulk measurement capabilities and analyzes

- Optional in-situ sample preheating/drying to 300 °C

Key Hardware Benefits

- Open stainless steel stand design enabling easy access to sample pan while reducing static electric charging

- Only system to measure organic vapor partial pressure directly using Ultrasonic Sensor (patent pending)

- Wide range (5-85 °C) and single uniform and accurate temperature enclosure

- Capable of upgrading to 5 balances

- Next generation control and assessment software for the most advanced experimental design and data analysis

- Optional IR, Raman and Video imaging with integrated control software

Download the Brochure for More Information

The only method to directly measure Solvent and Gas concentrations

New UltraSonic Sensor

Earlier techniques for directly measuring the solvent concentrations have either been non-existent (i.e. estimating the solvent concentration) using a specially configured dew point analyzer for the measurement. Increased customer demands for a more universal and more accurate measurement technology has led to SMS developing an innovative new sensor. The patent pending Ultrasonic Sensor in the DVS Resolution measures the vapor concentration using speed of sound (SOS) directly.

The SOS is directly associated with temperature, the absolute vapor concentration of the gas phase species and the chemical species present. This technology allows for true closed loop control by regulating the mass flow controlled vapor delivery using the real time speed of sound measurement. Besides the SOS being speedy (1s), it is reliable and a central gas phase property.

.png)

Sample UltraSonic data

Applications

Methanol Adsorption in Hair with Background Humidity

- Methanol adsorption at 40% P/Po in blue

- Water adsorption at 40% RH in red

- Methanol adsorption at 40% P/Po with 40% RH background humidity in green

Thin Film Co-Diffusion

- Independent control of individual moisture and organic vapor flows for single component and co-adsorption experiments

- Co-diffusion of two solvents into a thin film

Spray Dried Polymer Co-Adsorption Isotherms

Acetone Sorption in Background Humidity

- Acetone isotherm in red/10%RH background

- Acetone isotherm in blue/20%RH background

- Acetone isotherm in green/30%RH background

Modular Capabilities

Raman Spectroscopy

- Fully integrated software / hardware solution for activating and capturing Raman spectra during sorption experiments

- Allows for a more comprehensive understanding of vapor-solid interactions for materials

Optional Microscopy and Video

- 200x optical zoom

- Optional 5 MP color camera

- Grid overlay and calibration for measuring dimensional change

- Images have time-date-temperature humidity stamps

High Temperature Preheater for Drying, Curing and Vapor Generation at Elevated Temperatures

- In-situ degassing/activation of samples up to 300 °C

- The temperature is measured by Pt100 directly below sample pan

- Humidity generation up to 150 °C

Download the Brochure for More Information