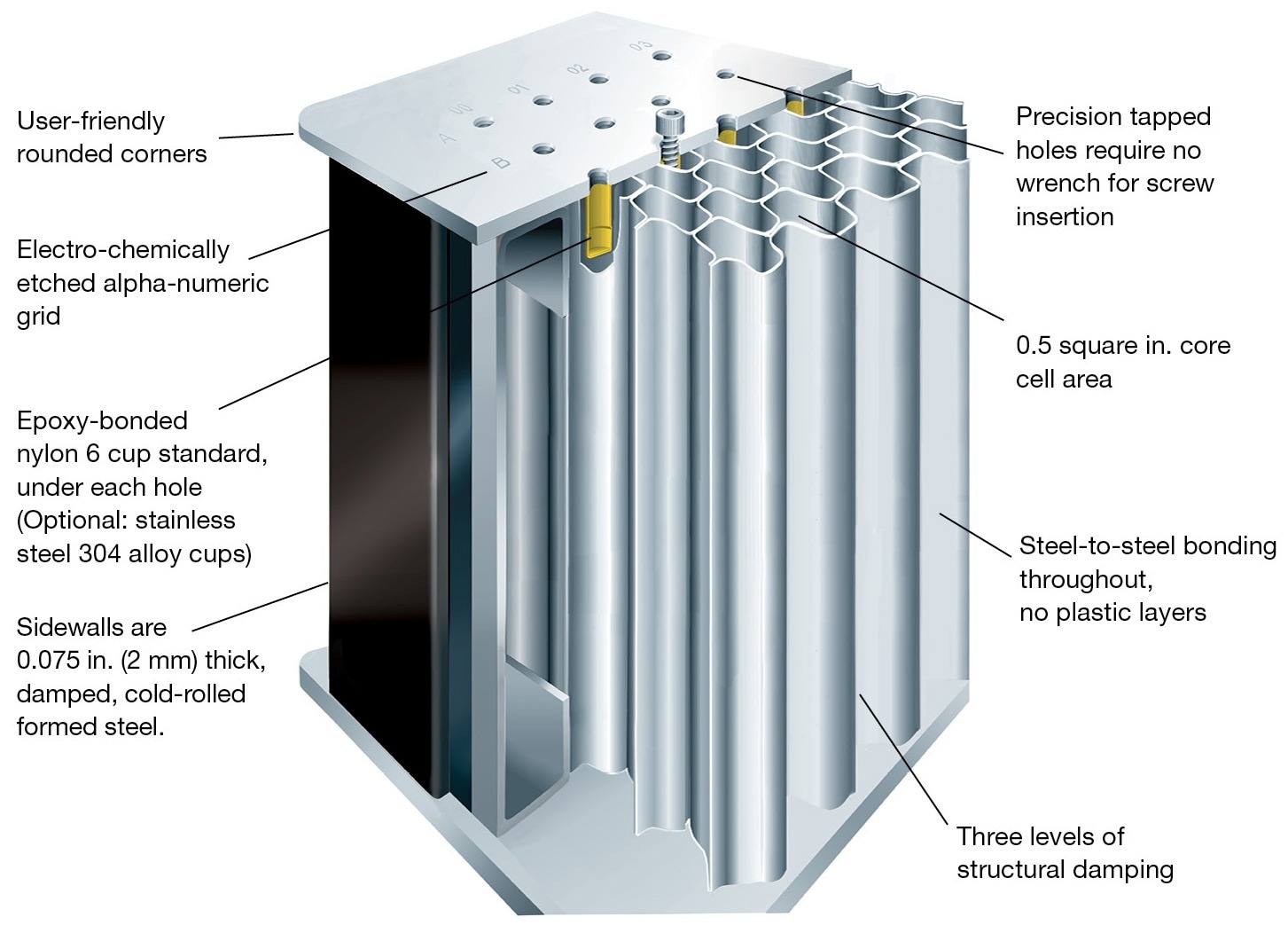

TMC’s optical tables and isolation systems offer industry-leading performance and rigidity thanks to an all-steel construction and the highest core density and smallest honeycomb cell area on the market.

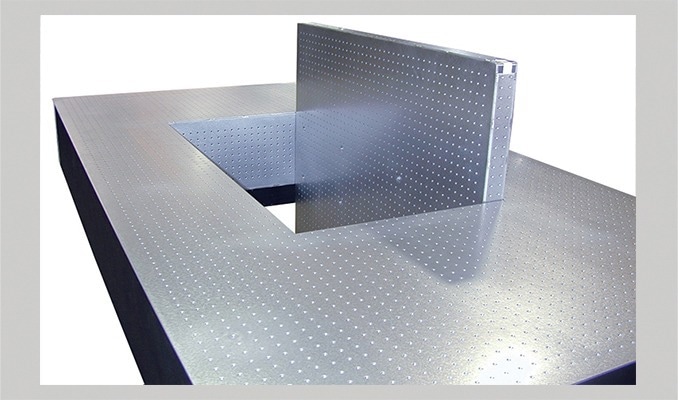

The CleanTop Performance series has three levels of damping performance and a multitude of configuration options for various use cases. Individual tables can even be mechanically coupled to create complex rigid table shapes without compromising damping performance.

The System 1 optical table support systems (sold separately) feature unmatched vibration isolation capabilities and the same design freedom.

Performance Levels

- Research Grade 784 Series: Provides the best optical top performance. Unmatched in the industry, Research Grade performance combines the smallest cell size and highest core density with the unique CleanTop® design, all-steel construction, and the highest level of structural damping commercially available.

Research Grade CleanTops are recommended for the most demanding applications, including interferometers, holography, ultra-fast lasers, and the most severe floor vibration environments. For the best overall vibration control, users should consider combining this top with a LaserTable-Base™ support, a hybrid air/piezoelectric, 2-stage vibration cancellation system.

- Scientific Grade 783 Series: The Scientific Grade system has the same design features as the Research Grade, such as core size and density, CleanTop cups, and all-steel construction with decreased damping. Peak compliance levels for Scientific Grade damping are four times higher than peak compliance levels for Research Grade damping.

- Laboratory Grade 781 Series: Provides a cost-effective degree of performance for the least sensitive applications in less severe floor vibration situations. The Laboratory Grade is suitable for common laboratory applications requiring a strong, flat mounting surface.

Image Credit: TMC Vibration Control

The CleanTop Advantage

- All steel construction: No particle board sidewalls or plastic layers are present between the top skin and the honeycomb core. This configuration guarantees the utmost in structural strength and integrity.

- Smallest core cell size, highest core density: The CleanTop design benefits from cylindrical cups, eliminating the need to enlarge the steel honeycomb core cell size. The standard cell size for CleanTop measures 0.5 in², which is a minimum of 50% smaller than the measurements achieved by plastic layer designs. This key distinction ensures optimal stiffness and a superior core-to-skin bonding contact area.

- Steel to steel to steel: With only two connecting layers (top skin to core and core to bottom skin), CleanTop creates a spill-proof core. Imitations must add a third bonding layer which weakens the structure: top skin to plastic layer, plastic layer to core, and core to bottom skin.

- Thermal stability: The CleanTop’s all-steel structure ensures materials with the same coefficient of thermal expansion, resulting in superior thermal stability

TMC’s CleanTop Optical Top is the most advanced way of creating a spill-proof, clean, accurate, and corrosion-resistant optical top with unrivaled structural performance. All TMC optical tops now have CleanTop as a standard feature.

Cups are made from chemically resistant nylon 6, however, stainless steel (304 alloy) cups are also available. Holes are tapped and countersunk before they adding the cups to allow the machined top sheet to be thoroughly cleaned with open, rather than blind, holes prior to bonding.

The top plate is processed through a custom TMC industrial cleaning center where a high pressure, high temperature cleaning solution is forced through each threaded hole, clearing any machining or tapping debris. Several rinse and dry cycles ensure a “sterilized” top surface before the cups are bonded.

CleanTop is another major advancement in TMC’s long optical top tradition of industry “firsts” including:

- First spill-proof optical top (CleanTop)

- First all-steel optical top

- First oil-free optical top

- First honeycomb core registered to the tapped hole array

- First lightweight breadboard with formed rather than drilled holes

- First vacuum compatible optical top

Features

- Liquid spills are contained on the surface and cannot reach the honeycomb core of the top.

- The core is completely dry and clean, with no residual thread-cutting oils that would need to be out-gassed.

- Screw insertion is smooth and easy thanks to the extremely clean tapped holes

- Small parts dropped into the holes can be easily retreived

- As dangerous chemicals used on the top’s surface are unable to penetrate the core, health hazards are unlikely to occur

20 Reasons for Choosing TMC CleanTop Optical Tops

TMC CleanTop®

TMC: Formed Steel Sidewalls. Image Credit: TMC Vibration Control

TMC: Steel-to-steel bonding throughout. Image Credit: TMC Vibration Control

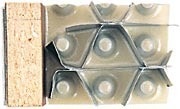

TMC: High stiffness, small cell size core, individual nylon cups. Image Credit: TMC Vibration Control

Competitive Construction

Other: Particle board sidewalls. Image Credit: TMC Vibration Control

Other: Weak plastic layer separates core and top skin. Image Credit: TMC Vibration Control

Other: Less rigid, large cell size core; molded plastic cups. Image Credit: TMC Vibration Control

- TMC tops’ sidewalls are made of damped, cold-rolled formed steel that is 0.075 in. (2 mm) thick, as opposed to the preferred low cost, moisture-absorbing particle board of other manufacturers. Additionally, steel provides structural integrity that cannot be obtained with particle board sidewalls.

- Compared to molded plastic membrane cavities, which are conical, CleanTop cups are cylindrical; hence TMC’s design does not need to enlarge core cell size. The average cell size is 0.5 in.2 (3 cm2), which is at least 50% smaller than designs for molded cavity tops. This ensures the maximum stiffness and the largest core-to-skin bonding contact area.

- With just two bonding layers — the top skin to the core and the core to the bottom skin — CleanTop creates a core that is spillproof. The structure is substantially weakened in imitations as a third bonding layer must be added between the top skin, plastic layer, and core, as well as between the core and bottom skin.

- Furthermore, to avoid excessive epoxy being pressed into the plastic cups, imitative designs utilize just the thinnest layer of epoxy between the top skin and the plastic layer. The thinness of this layer could cause “voids” when the top is connected by trapping air, severely weakening the bond

- TMC uses a proprietary process to clean machined skins to a level that is virtually “sterilized.” This ensures that the threaded holes are as clean as possible and have superb epoxy bonding. Furthermore, the cleaning station is in an entranceway to a clean, finishing building so that the cleaned top never sees a heavy, industrial machining environment. Thanks to the the CleanTop® design, no machining, grinding or sanding of any kind is performed after this cleaning process.

- TMC top skins are stretcher-leveled, stress-relieved, and pressure-bonded to a precision-lapped granite plate without further grinding, therefore minimizing heat and stress. The completed top is guaranteed to be flat within 0.005 in. (0.13 mm) of the full tapped hole pattern, regardless of top size.

TMC top skin (left) and competitive design top skin (right) after grinding. Image Credit: TMC Vibration Control

- TMC tops’ top surfaces are softly sanded with an orbital pattern to eliminate burrs and produce a non-glare, non-reflective finish without causing internal stress.

TMC top skin (left) and competitive design top skin (right) after grinding. Image Credit: TMC Vibration Control

- Standard mounting holes in TMC tops are tapped, either 1/4–20 on 1-inch centers or M6 on 25 mm centers. Imperial 1/4-20 tapped holes on 1-inch staggered centers and metric M6 on 25 mm staggered centers are available at an additional fee. Custom patterns, including large through-holes for cables, etc., are also easy to achieve thanks to TMC’s multiple 2,000-watt laser machining centers.

- All TMC mounting holes are aligned with the honeycomb core’s open cells (a feature of CleanTop®, but not necessarily other designs). This safeguards the core from harm during manufacturing, ensuring the structural integrity is preserved and that all mounting screws can be easily inserted.

TMC registered holes (shown without CleanTop® cups.) (left), Competitive non-registered holes (right). Image Credit: TMC Vibration Control

- Every hole is lead-screw-tapped in a TMC top, the most precise method currently available, and no inserts are required. Inserts can loosen, and top skins can be distorted when inserts are pressed into undersized holes.

TMC countersunk holes (left) versus non-countersunk holes in competitive design (right). Image Credit: TMC Vibration Control

- To eliminate ridges and burrs, TMC mounting holes are slightly countersunk. At first insertion, each TMC mounting screw can be finger-tightened; a tool is not required.

- TMC’s broadband dry-damping method is the only logical one for an optical top. Others use "tuned" dampers which only work on a discrete frequency. Structural resonances are not discrete and therefore do not eliminate but rather "split" into two resonances when using tuned dampers.

- The honeycomb core of the TMC is constructed of 0.010 inches (0.25 mm) of work-hardened steel that has been plated to prevent corrosion and ensure a longer lifetime. Steel honeycomb is the ideal material for optical tops as its Young’s modulus is three times that of aluminum.

- TMC’s honeycomb core is a closed-cell structure with a basic cell size of 0.5 in.2 (3 cm2), giving a core density of 13-14 lbs/ft3 (300 kg/m3), significantly greater than others on the market. The effective core density is 18-20 (16 lbs./ft3) including sidewalls and dampers.

TMC’s honeycomb core. Image Credit: TMC Vibration Control

- The honeycomb structures are entirely produced by TMC, which guarantees low production costs, superior quality, and precise dimensional control.

- TMC tops’ core, skins, and sidewalls are firmly and permanently bonded with a specially designed high-strength epoxy that has no viscoelastic creep or hysteresis. The total shear modulus of TMC’s final bonded core is 275,000 psi (19,300 kg/cm2).

- The stainless steel version of TMC’s CleanTop cups offers the ultimate in an unbroken stainless steel barrier. This design means that the top is immune to even repeated spills of the most corrosive liquids.

- Structural damping of TMC tops is achieved via the use of broadband mass dampers. These are separate from the core, do not permit hysteresis or creep of the top, and do not detract from the top’s stiffness.

- The unique, direct core-to-top bonding enhances the thermal conductivity of the core to the outside environment, lowering the “thermal relaxation time” for the top.

- All of TMC's skins, core, sidewalls, and dampers are made of steel and thus have the same coefficient of thermal expansion. Therefore, even in situations with repeated temperature cycling, a TMC top expands and contracts as a whole, assuring structural integrity and preventing long-term internal stress buildup.

Image Credit: TMC Vibration Control

Specifications

- Core: Steel honeycomb, closed cell, 0.01-inch (0.2 mm) thick foil

- Core shear modulus: 275,000 PSI (19300 kg/cm2)

- Core cell size: < 0.5 inch2 (3 cm2)

- Core density: 13.3 lb/ft3 (230 kg/m3)

- Flatness: +/–0.005 inch (0.13 mm) within the entire tapped hole pattern, regardless of table size | +/– 0.004 in. (0.1 mm) over a 2 × 2 ft (60 × 60 cm) area

- Top skin: 400 series 3/16 inch (5 mm) thick ferromagnetic stainless steel

- Sidewalls: Damped formed steel channel covered with vinyl

- Tapped holes: Backed by 1-inch (25 mm) long CleanTop nylon cups. Steel cups are optional.

Performance

Damping Performance Comparison Between Grades

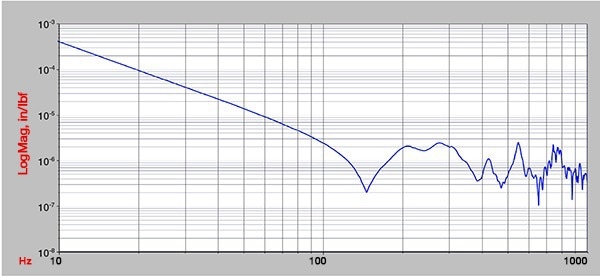

Research Grade: corner compliance data measures the displacement of the table in response to impact by a calibrated hammer. The lack of response below 300 Hz is indicative of extremely high damping and excellent overall structural performance. Compliance was measured on a 48×96×12 in. table. Image Credit: TMC Vibration Control

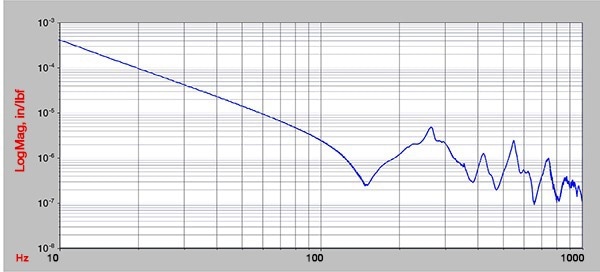

Scientific Grade: corner compliance data shows higher peak compliance value than the Research Grade. Compliance was measured on a 48×96×12 in. table. Image Credit: TMC Vibration Control

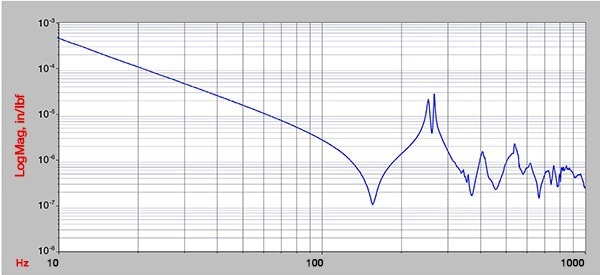

Laboratory Grade: Corner compliance data shows higher amplification at the table’s resonant frequency. Compliance was measured on a 48×96×12 in. table. Image Credit: TMC Vibration Control

Structural Damping

TMC has long believed that dry damping of an optical top is superior to oil-based dampers. Oil’s properties vary over time; therefore, concealed oil reservoirs are constantly at risk of being penetrated by an end-user personalizing his system.

TMC's approach to damping structural resonances has always been based on "broadband damping."

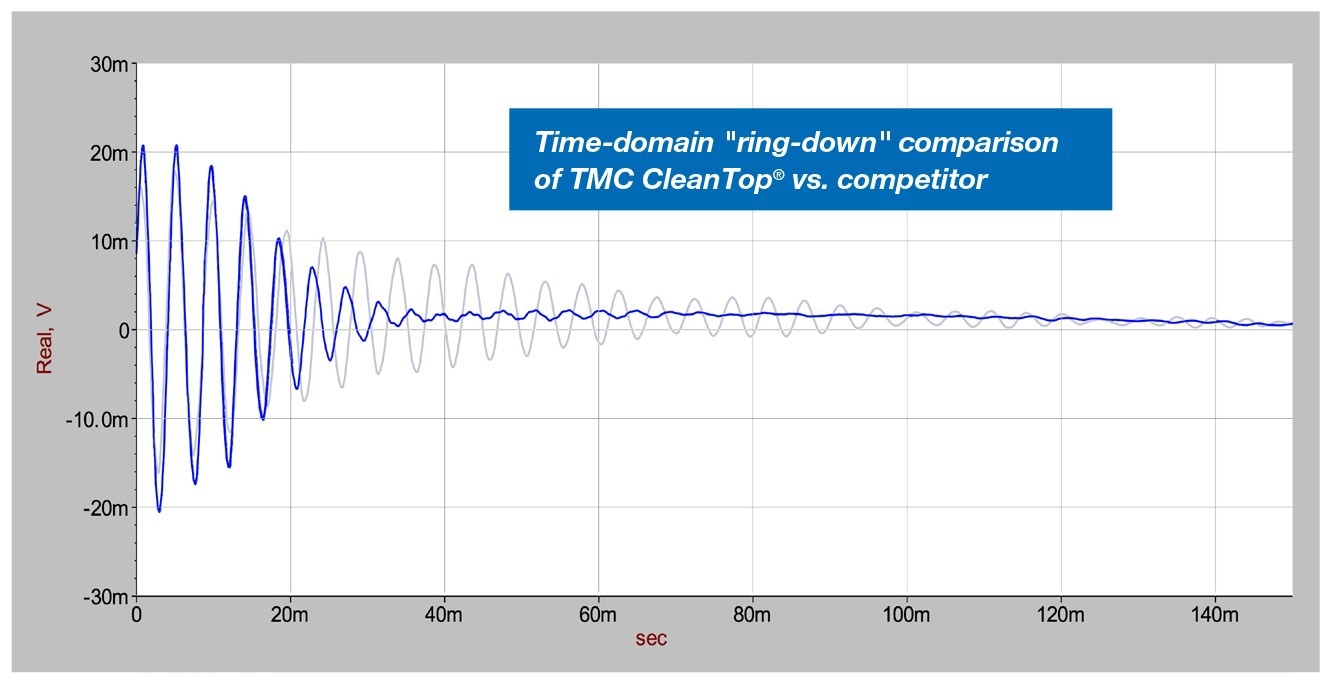

"Tuned damping," or using a tuned mass damper to resonate out-of-phase with a top's bending mode, is a risky strategy. Firstly, it hinges on the assumption that the damper can be synchronized with the top's resonant frequency.

However, the resonant frequency of an optical top is subject to fluctuations due to factors like load variations, load distribution, temperature changes, and even the presence of dampers themselves. Therefore, in practice, tuning the dampers to the top's resonance is difficult. Furthermore, it assumes that only the lowest resonant frequency will need damping when various other secondary bending and twisting modes may also need attention.

More importantly, the concept of integrating a tuned mass damper to mitigate structural resonance is fundamentally flawed. Tuned damping can only attenuate discrete resonances and is misapplied when used to dampen a broadband structural resonance. In other words, a tuned damper essentially "divides" a structural resonance into two separate resonances by introducing a coupled mass system.

Image Credit: TMC Vibration Control

The most effective approach to dampen an optical top is with TMC’s unique broadband damping techniques. This method dissipates energy at the top’s primary, secondary, and higher resonant frequencies throughout the whole frequency range of interest. It is also worth noting that adding weight to the top will not impair performance.

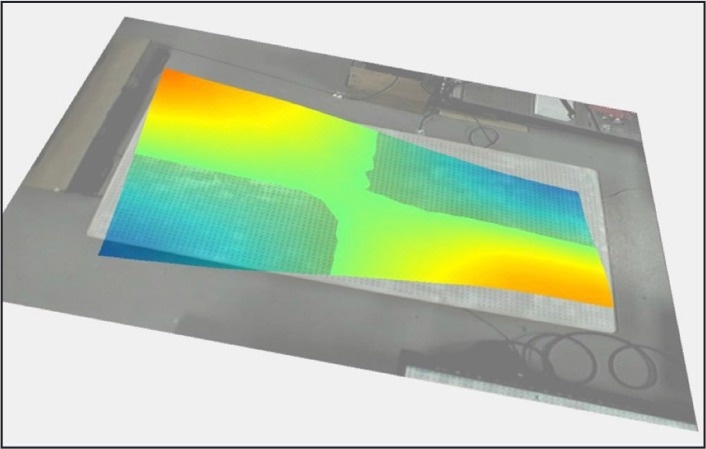

TMC CleanTops are designed and engineered utilizing the most modern structural analysis and design technologies. The below Operational Deflection Shape was determined using a technique known as Laser Scanning Vibrometry (LSV). LSV is one of the most sensitive and accurate non-contact vibration monitoring systems currently on the market. It measures the behavior of the entire table rather than one discrete place using the laser Doppler effect.

Image Credit: TMC Vibration Control

Structural Damping Performance Summary

TMC optical tops have guaranteed unsurpassed performance levels. Additionally, due to the three levels of broadband damping and three environmental options available, TMC offers the highest flexibility when it comes to choosing a performance level.

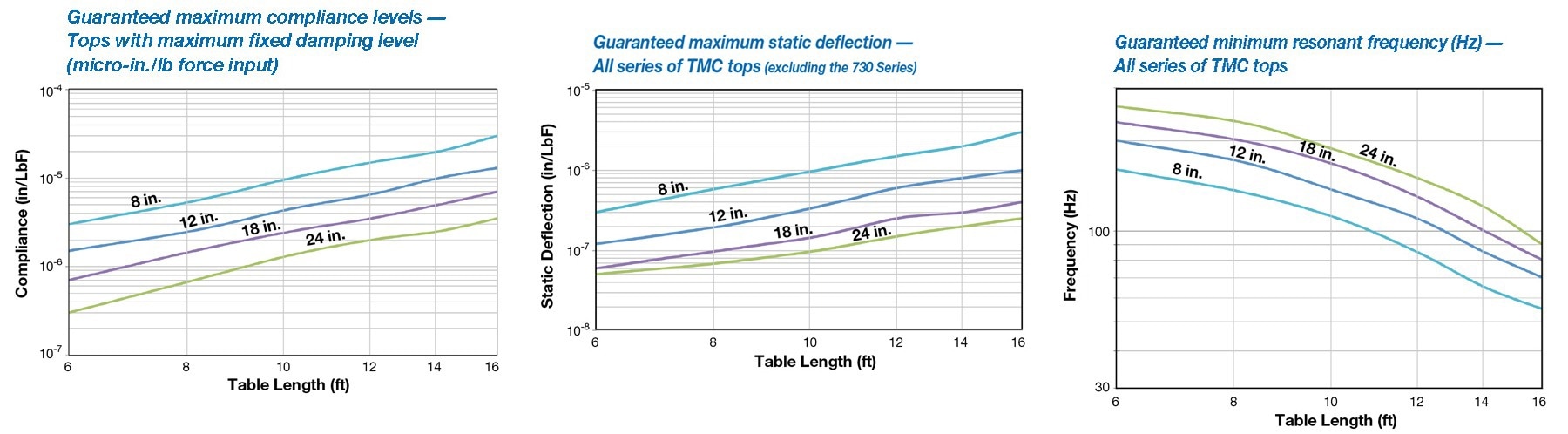

Guaranteed maximum compliance levels for the maximum damping level are outlined in the graphs below.

The standard damping level provides compliance levels that are four times greater than those listed in the tables. The minimum damping level is advised solely for non-sensitive applications.

The plotted curves depict the assured performance benchmarks of TMC optical tops. Moreover, compliance data for tabletop corners across the three available damping levels is provided. The data was collected through impact testing, utilizing a one-pound calibrated hammer, an accelerometer, and a dual-channel spectrum analyzer. These graphs illustrate that the measured performance often surpasses our guaranteed standards.

Image Credit: TMC Vibration Control

Support (Leg) Options

TMC provides a wide range of leg solutions for CleanTop optical tables.

Traditionally, optical tables pair well with Micro-g pneumatic vibration isolation devices, which offer the best value for money.

They feature stiff non-isolating legs for less vibration-sensitive applications, while ultra-sensitive equipment will benefit from STACIS piezoelectric vibration-canceling technology solutions, such as LaserTable-Base.

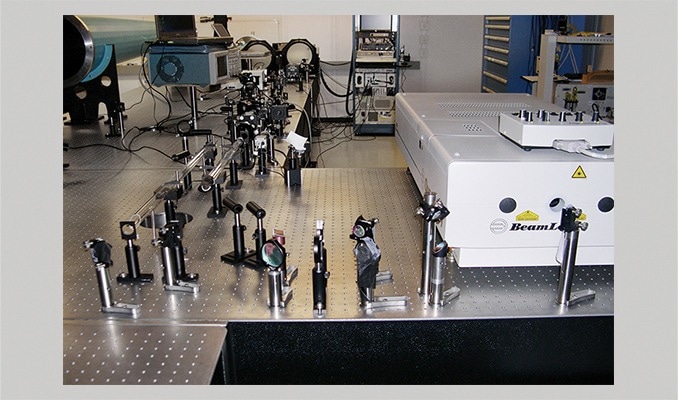

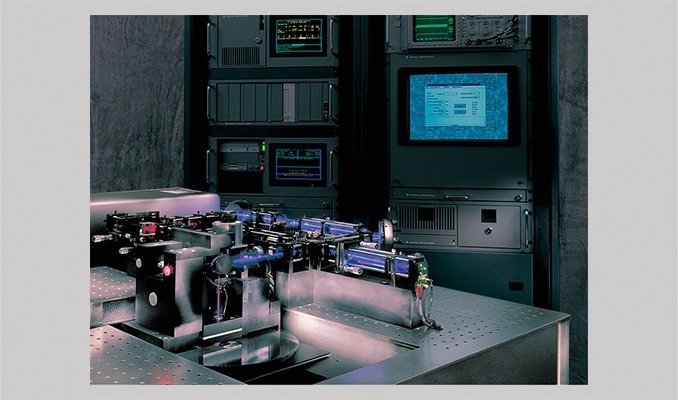

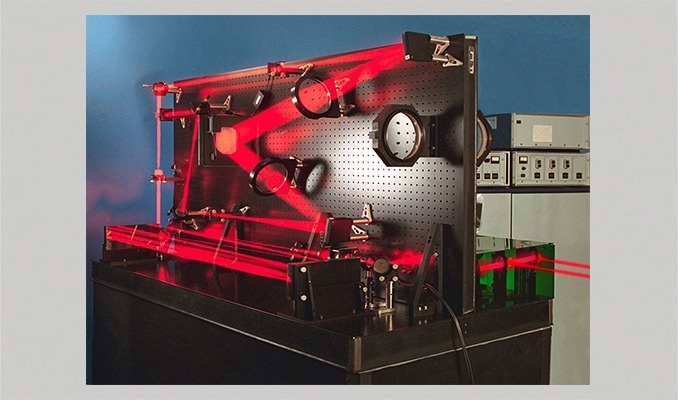

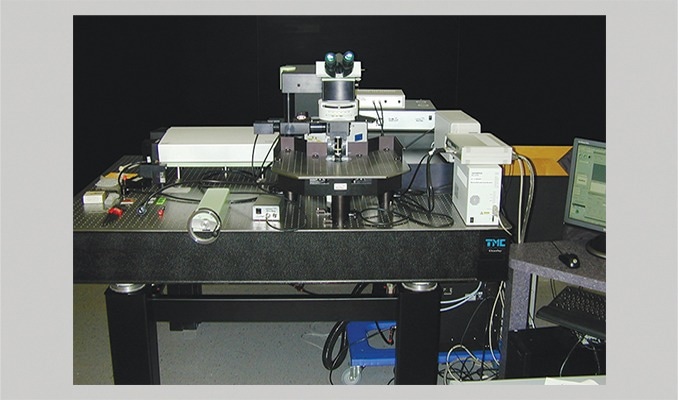

Application Photos

Image Credit: TMC Vibration Control

Image Credit: TMC Vibration Control

Image Credit: TMC Vibration Control

Image Credit: TMC Vibration Control

Image Credit: TMC Vibration Control

Image Credit: TMC Vibration Control

Image Credit: TMC Vibration Control

Setup Guides (Video)

Part 1 - TMC Optical Table Setup Video

CleanTop® optical top and System 1 supports installation steps part 1. Video Credit: TMC Vibration Control

Part 2 - TMC Optical Table Setup Video

CleanTop® optical top and System 1 supports installation steps part 2. Video Credit: TMC Vibration Control

Part 3 - TMC Optical Table Setup Video

CleanTop® optical top and System 1 supports installation steps part 3. Video Credit: TMC Vibration Control

Joined Tables Setup

Instructions on how to join multiple optical tops with rigid couplings. Video Credit: TMC Vibration Control