Semiconductor manufacturing factories (fabs), Nanotechnology Centers, Nanofabs, and other precision manufacturing and research facilities often incorporate a system of raised false floors into their cleanrooms to maintain strict cleanliness standards and to accommodate complex facilities requirements (plumbing, electrical cables, gas piping, etc.).

Such floors, however, often make the installation of vibration-sensitive production, inspection, and metrology equipment rather challenging.

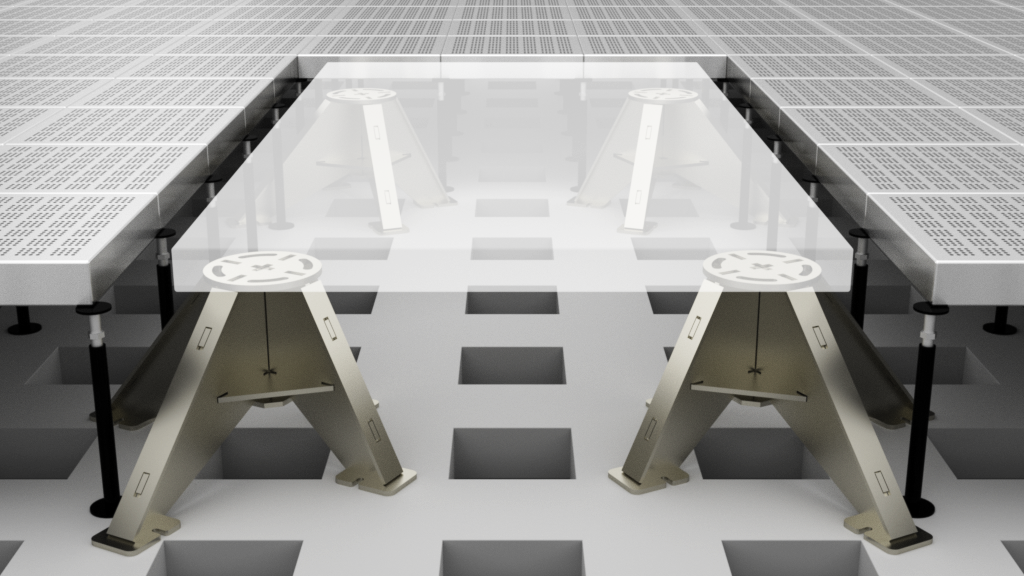

The raised floors cannot provide the necessary quiet vibration environment for such tools. TMC's Quiet Island® is an innovative solution that replaces a section of the raised floor area with a "Quiet Island" anchored to the sub-floor below. The Quiet Island is made up of a cleanroom-compatible platform top combined with an application and site-specific support structure.

Vibration Cancellation

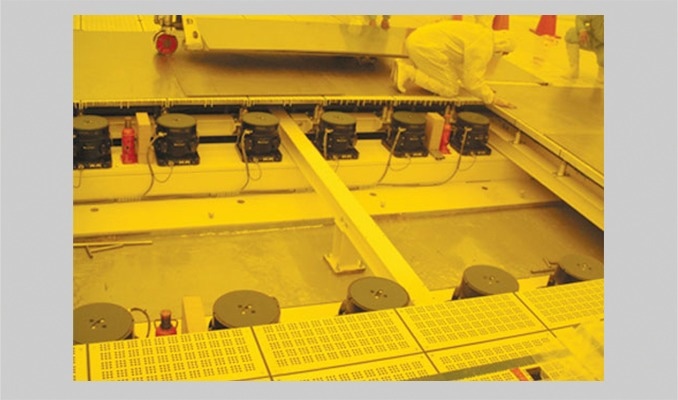

The main support element and core technology unique to the Quiet Island is the STACIS III Active Vibration Cancellation System. This form of "rigid" style inertial vibration cancellation support proves indispensable for vibration-sensitive instruments, empowering them to function at their utmost potential even within environments characterized by high noise levels.

STACIS III is compatible with automated wafer processing tools, high-resolution eBeam imaging tools, ion-beam milling tools, and any tool with internal vibration isolation systems, both passive and active. In addition, it provides the most vibration isolation across the widest frequency range commercially available.

The "hard-mount" design also boasts exceptional stiffness, ensuring that there are no stability concerns for tall, top-heavy tools. With STACIS IIIc isolators, a more compact version of the Quiet Island can be developed for very short raised floors.

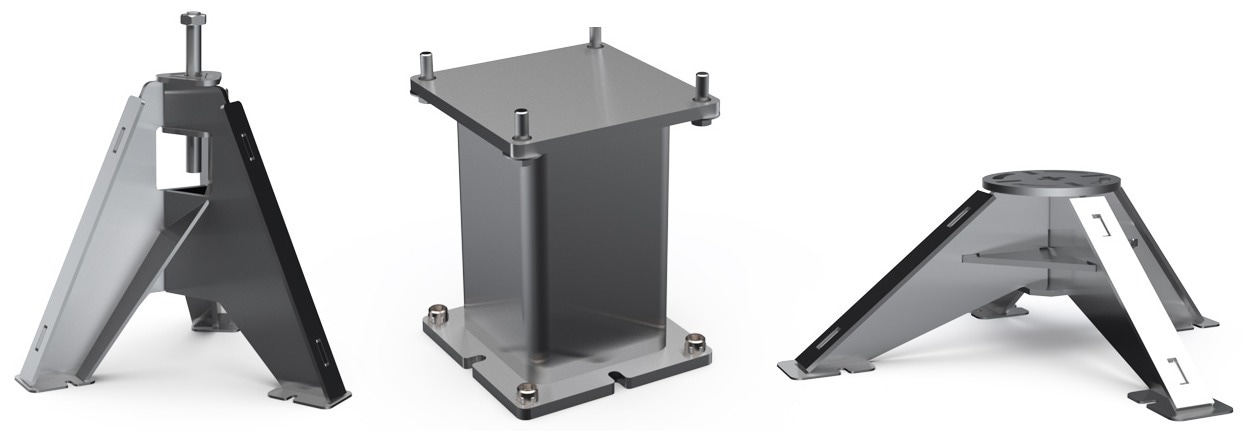

Risers and Supports

TMC's experienced engineering team design and manufacture extremely rigid and durable risers to support STACIS isolators. These are manufactured to high standards in compliance with ISO 9001 welding certifications.

Every Quiet Island is programmed to be compatible with various sub-floor geometries, raised floor heights, and tool footprints. With thousands of installations internationally supporting more than 200 different instrument models, TMC has the experience and knowledge to engineer a support structure fulfilling the requirements of STACIS and the user’s facility.

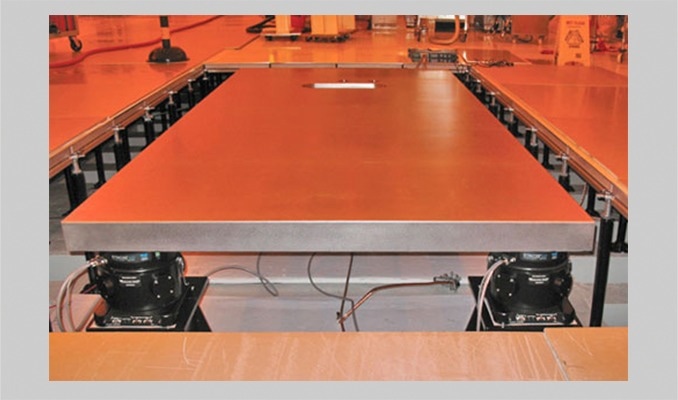

Rigid Platform

The raised floor platform is a TMC designed and manufactured 4-inch (100 mm) thick lamination of steel plates positioned around an incompressible, lightweight, damped core material. The layering impact of rigid steel plates and core, epoxy bonded into an all-in-one, stainless steel pan, offers a very high level of structural damping and stiffness.

The huge cross-section and steel content generate a very high level of total rigidity. The sides and top are a one-piece, continuous stainless steel shell to preserve the appearance, cleanliness, and integrity of the system. TMC manufactures and designs the platforms dedicated to the application that incorporate unique shapes, cutouts, lifting bolts, and tiedown holes as needed.

Quiet Islands vs. Quiet Buildings

Developing a facility to fulfill the strict Vibration Criteria of very accurate imaging equipment can be very difficult and usually expensive, specifically when not all tools in the facility need such low vibration levels.1

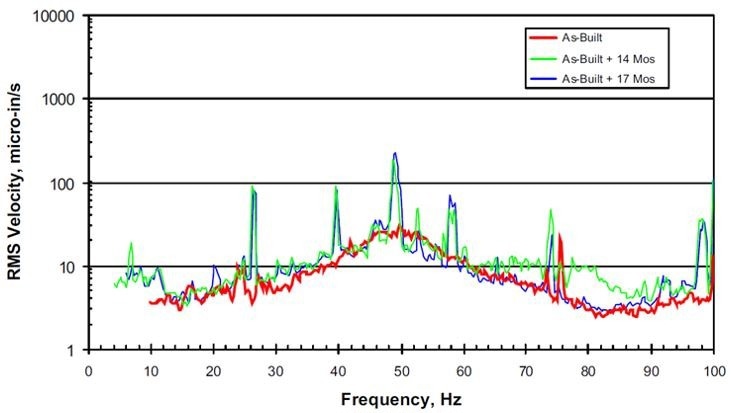

Statistical representation (in terms of Mean plus Sigma Spectra) of vertical vibrations in a typical semiconductor fab production area at "as built" and two times thereafter.2 Image Credit: TMC Vibration Control

It can be extremely challenging to isolate huge regions like complete buildings or a complete floor. It is also well documented that building vibration levels will increase relative to a design specification as the facility becomes populated with people and equipment. Recurrent vibration measurements have shown that floor vibration levels usually increase over time.2

The more successful and cost-effective way to achieve the stringent requirements of vibration-sensitive tools is to employ point-of-use active vibration control with serial piezoelectric technology, particularly to mitigate challenging low-frequency (less than 5 Hz) vibration.

TMC prides itself on being able to work alongside any team to design a tool-specific Quiet Island solution. This process allows TMC to gain insight into each specific tool and provide the best-performing solution.

A building design that incorporates one large concrete sub-floor “slab” with a “raised floor” allows for flexibility of tool selection post-construction. Replacing the raised floor with a Quiet Island only where needed provides the most sensitive tool set with a vibration environment an order of magnitude, at least, lower than the sub-floor.

The Quiet Island Advantage

- Incorporates STACIS – TMC's active piezoelectric vibration cancellation technology is the best in the business, with its “hard mount” design and isolation that begins at 0.6 Hz, compatible with tools incorporating internal isolators.

- Modularity, customization, and relocation flexibility - All platforms are exclusively customized to customers' applications, but they can be seamlessly reconfigured if the floor or the tool characteristics change, unlike concrete plinths.

- Expertise - TMC has vast experience working with the world's top semiconductor manufacturers, ultra-precision OEMs, and scientific facilities.

Performance

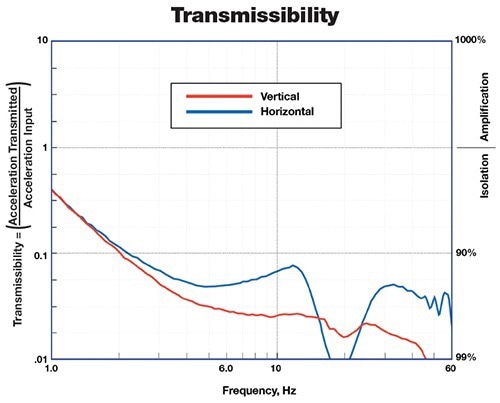

Measured transmissibility on a 24” tall 40”x60” Quiet Island, 4-mount STACIS support, VC-C input from the floor. Image Credit: TMC Vibration Control

Specifications

Source: TMC Vibration Control

| . |

. |

| Platform surface |

Stainless steel surface top and sides;

epoxy painted steel bottom |

| Platform construction |

Proprietary multi-layer steel laminate |

| Dimensions |

Build to suit |

| Standard heights |

15, 18, 20, 24, 30, 36, 48 in.

38, 46, 51, 61, 76, 91, 122 cm

Custom heights also available |

| Load capacity |

Build to suit |

| Rigid risers and supports |

Certified welding, all-steel construction,

cleanroom compatible powdercoat finish |

| Options |

Restraint brackets, platform top eyebolts for lifting,

bridge plates for waffle-type subfloors |

| Platform top variations |

Cutouts, thru-holes, tapped holes for tool tie-downs |

Other Quiet Island Configurations

Large instruments that do not have a vibration specification for the environment that they are in often require a rigid and stable support that is separate from the raised floor. In instances like this, the Rigid Quiet Island is the ideal solution.

With the same high-performance platform top, Rigid Quiet Islands are also custom engineered for installations in raised floor cleanrooms with any height, any sub-floor geometry, and for a variety of tool footprints.

TMC provides an array of support tailored to meet various requirements, yielding a solution precisely suited to the instrument and facility. This approach remains modular, enabling effortless relocation, while also allowing for seamless upgrades when necessary.

Image Credit: TMC Vibration Control

Image Credit: TMC Vibration Control

Application Photos

Image Credit: TMC Vibration Control

Image Credit: TMC Vibration Control

Image Credit: TMC Vibration Control

Image Credit: TMC Vibration Control

Image Credit: TMC Vibration Control

Videos

TMC Quiet Island for Cryo Electron Microscopes

Typical setup of a Quiet Island under a cryo electron microscope. Video Credit: TMC Vibration Control

TMC Vibration Control -- STACIS 2100 installation

Quiet Island isolated raised floor installation steps. Video Credit: TMC Vibration Control

References

1Evolving criteria for research facilities: I – Vibration, Colin Gordon Associates, SPIE Conference 5933: Buildings for Nanoscale Research and Beyond, 2005, Source

2Maturation of the Vibration Environment in Advanced Technology Facilities, Colin Gordon Associates, Journal of the IEST, V. 48, No. 1, 2005, Source