With a multi-sample cell that provides high-quality heat flow data for up to three samples at once, TA Instruments encourages users to explore the possibilities of the Discovery X3 Differential Scanning Calorimeter.

Industry-leading performance and the means to boost output at all material research levels are combined in the Discovery X3 DSC.

Due to TA Instruments’ dedication to innovation, scientists and engineers can accomplish their objectives more quickly and make important decisions with confidence.

Features and Benefits

- The Fusion Cell™, equipped with patented technology, delivers unparalleled performance in baseline flatness, sensitivity, resolution, and reproducibility. This exceptional technology empowers the detection of the most subtle thermal transitions and ensures precise measurements of enthalpy and specific heat capacity.

- The advanced Tzero heat flow technology incorporated in the X3 ensures concurrent temperature and enthalpy accuracy across all three samples.

- With high-end performance, the trio of sample calorimeters offers unparalleled flexibility, accommodating tasks ranging from replicate testing for statistical analysis to validation/verification against a control sample, ensuring the utmost certainty in results.

- One-Touch-Away™ User Interface increases the usability and access to data on the instrument.

- Modulated DSC® (MDSC®) for the most efficient separation of complex thermal events.

- The dependable linear autosampler features 54 programmable tray positions, guaranteeing worry-free 24/7 operation. Its flexible programming capabilities for experiments and automated calibration and verification routines add to its reliability.

- The broad spectrum of refrigerated cooling options eliminates the need for liquid nitrogen expenses, ensuring uninterrupted sub-ambient operation even during extended autosampler routines.

- Tzero Press and pans for rapid, simple, and reproducible sample preparation.

- Robust software that delivers an exceptional user experience in a combined package for instrument control, data analysis, and reporting. Equipped with features like automated calibration routines and real-time test method editing, which provide unmatched flexibility, while One-Click analysis and custom reporting raise productivity to new levels.

- Commitment to quality backed by the industry’s ONLY five-year cell and furnace warranty for peace of mind.

TA Instruments has established a benchmark in the field of Differential Scanning Calorimetry (DSC), achieving best-in-class performance without requiring pre- and post-test data manipulation commonly found in competing products. The Discovery Series DSCs offer both novice and advanced users the utmost confidence in producing superior data, simultaneously enhancing laboratory workflows and overall productivity.

Specifications

Innovative Technology, Unmatched Productivity, Extraordinary Possibilities. Source: TA Instruments

| Instrument Features |

X3 DSC |

| Fusion Cell™ |

● |

| MDSC® |

● |

| Enhanced Tzero Heat Flow |

● |

| User Replaceable Cell |

● |

| 54-Position Autosampler |

● |

| Dual input Gas-Delivery Manifold |

● |

| Color App-Style Touch Screen |

● |

Included

Included

Source: TA Instruments

| |

X3 DSC |

| Baseline Flatness (-50 to 300 °C) 1 |

≤10 μW |

| Baseline Repeatability (-50 to 300 °C) |

<15 μW |

| Temperature Range |

-180 °C to 550 °C |

| Temperature Accuracy |

±0.025 °C |

| Temperature Precision |

±0.005 °C |

| Enthalpy Precision |

±0.08 % |

| Heating/Cooling Rate |

0.01 °C/min to 200 °C/min |

1 No Baseline subtractions

2 Maximum rates depend on temperature and cooling accessory

Technology

Fusion Cell™

Image Credit: TA Instruments

The NEW TA Fusion Cell™, the centerpiece of every Discovery DSC, combines patented Tzero® technology, new unique manufacturing techniques, and design concepts that “FUSE” together the greatest elements of the first-generation Discovery DSC and the bestselling Q-Series in the world.

The Discovery DSC, in contrast to competing designs, achieves peak performance with a single sensor, removing the requirement to switch sensors to maximize a particular performance factor. As a result, a cutting-edge new DSC with unparalleled repeatability, sensitivity, baseline flatness, and resolution has been created.

Features and Benefits

- Unique cooling rods and ring design produce superior cooling performance over a wide temperature range, higher cooling rates, and more responsive heating to cooling operation

- Temperature-controlled electronics ensure the utmost stability and repeatability of measured signals

- Rugged uniblock silver furnace with long-life windings ensures superior temperature control and uniformity

- Innovative gas delivery manifold provides gas switching and a consistent, repeatable atmosphere

- A multi-sensor adaptation of TA’s ground-breaking Discovery DSC Fusion Cell

- Patented Tzero technology measures the cell resistance and capacitance (ability to store energy) characteristics. It delivers a fundamentally more accurate heat flow measurement with incomparable baseline performance while eliminating the need for baseline corrections prevalent in all other competitive offerings

- Fixed X3 sensor provides a stable configuration with a well-defined and reproducible heat flow path

The most accurate measurement of heat flow is provided by the Fusion Cell. It is never essential to do laborious pre- and post-test modifications like baseline subtractions or de-smearing processes that are mandated by competitive designs.

Tzero® Technology

Image Credit: TA Measurement

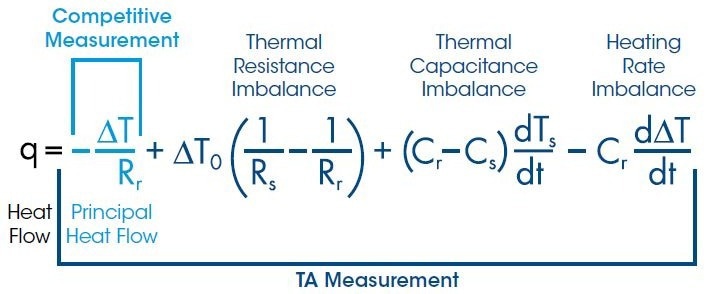

The same assumption has underpinned DSC heat flow measurements for a long time: the sample and reference sensor’s contributions to the total measured heat flow simply cancel each other out. All DSCs would have baselines that are perfectly flat if this assumption were correct. However, they do not.

The truth is that the resistance and capacitance (or capacity to store energy) of each sensor cause imbalances in the heat flow, which lead to variations from the baseline flatness as well as decreased sensitivity and resolution. With its patented Tzero Technology, Only TA Instruments can measure this imbalance.

Tzero Technology removes complex pre- and post-test manipulations, like baseline subtraction, deconvolution, or other mathematical operations that competitive designs need to perform to increase sensitivity, resolution, and baseline performance.

With the use of patented Tzero Technology, the resistance and capacitance of the sensors are measured and utilized in the four-term heat flow equation to provide the most precise real-time heat flow determination on any DSC.

By adding the DSC pans’ contributions, TA engineers have gone one step further. The T4P heat flow, an Advanced Tzero technology, offers the highest sensitivity, the sharpest resolution, and the ability to measure heat capacity in a single run.

Features and Benefits

- By improving every aspect of performance, the Discovery DSC delivers data the user can trust, in all applications, all the time

- Direct measurement of heat capacity delivering the most uniform and accurate heat flow to and from the sample

- Flattest baselines available of any DSC on the market, resulting in the purest data without manipulation or subtraction

- Highest resolution and sensitivity, without ever needing lengthy pre- and post-test manipulations as required by competitive designs

Modulated DSC

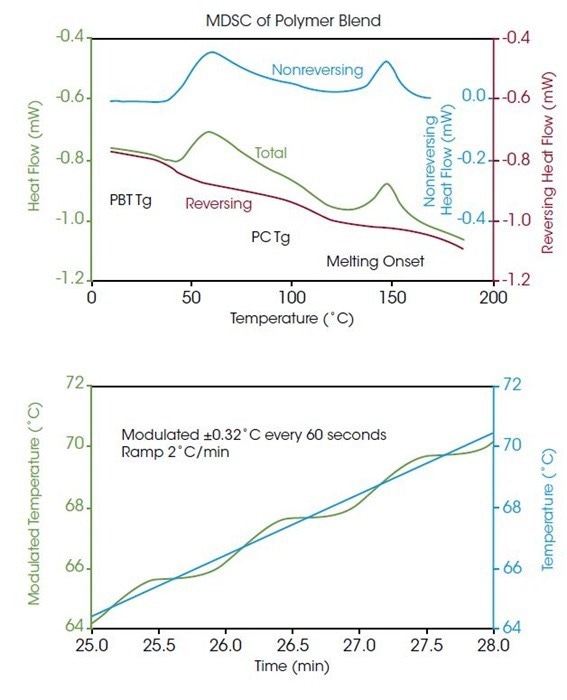

Modulated DSC, with MDSC®’s assistance, can interpret data with confidence. Through deconvolution of the Total Heat Flow signal, events such as a glass transition masked under an evaporation peak, or the simultaneous occurrence of a cold crystallization with a melt, are easily revealed.

Image Credit: TA Measurement

A sinusoidal temperature oscillation is superimposed on the conventional linear ramp in TA’s patented MDSC. Overall, this means that measurements of heat flow can be made both independently and concurrently with variations in heat capacity. As with standard DSC, the total heat flow signal is the total of all thermal transitions.

The reversing and non-reversing heat flow signals are separated from the total heat flow by modulated DSC. Glass transition and melting transitions are present in the reversing heat flow, which is made up of the heat capacity component.

The kinetic component, the non-reversing heat flow, includes processes like volatilization, melting, decomposition, and curing. TA created MDSC and is the only company that truly understands it. Every discovery DSC model comes equipped with modulated DSC as standard equipment.

Benefits of MDSC include

- Direct measurement of heat capacity

- Increased resolution without loss of sensitivity

- More accurate measurement of polymer crystallinity

- Separation of complex and overlapping transitions into more easily interpreted components

- Increased sensitivity for detecting weak transitions

Reliable Automation

Image Credit: TA Measurement

It is impossible to think that the most dependable DSC autosampler on the market could have been improved, but it was. To provide the highest level of testing flexibility, the new linear autosampler was made to be even more durable and user-friendly than its predecessor.

Autosampler Features and Benefits

- Convenient design allows the choice of unloading pans back to the tray or disposing of them freeing space for continuous sample queuing

- New Linear X-Y-Z design with integrated auto lid reduces sample loading time for increased throughput and reliability

- Scheduled and unattended calibrations and verifications give scientists more time for research

- The integrated auto lid gives consistent and repeatable cell closure further improving the repeatability of measurements

- Sample and reference pans may be assigned to any combination of the available 54 positions. Includes two quick-change trays for more convenient remote sample preparation

- New laser positioning system enables one-touch automatic calibration and pan location verification

- TRIOS software makes it easier than ever to manage and run a large and diverse sample queue. The design view and running queue allow for quick and efficient autosampler programming

APP Style Touch Screen

Image Credit: TA Measurement

The X3 DSC features TA’s innovative touch screen, making operation easier than ever with enhanced One-Touch-Away™ functionality.

Touch Screen Features and Benefits

- Resilient, responsive touch screen for an enhanced user experience

- Ergonomic design for enhanced accessibility and productivity

- Packed with functionality to simplify instrument operation

The One-Touch-Away™ interface includes

- Test and instrument status

- Start/stop controls

- Advance to the next step in method

- View active method

- Real-time signals and plot

- Autosampler calibration

- System information

- Load/unload plans

Utilize TA’s potent TRIOS software, the most dependable DSC autosampler available, and the One-Touch-AwayTM interface to significantly increase laboratory productivity and workflow. For a more straightforward and user-friendly interaction, these features allow automated calibration and verification procedures that operate flawlessly together.

Accessories

Refrigerated Cooling Systems (RCS)

Image Credit: TA Instruments

Benefit from the easy-to-use Refrigerated Cooling Systems (RCS) for DSC and MDSC® functioning at a wide temperature range when left alone. As the only liquid nitrogen-free system that can conduct experiments down to -120 °C, the new RCS 120 offers improved safety.

RCS Features and Benefits

- Safe, convenient, and continuous cooling operation for laboratory needs

- One-, Two-, or Three-stage refrigeration systems that achieve temperature ranges down to -40 °C, -90 °C or -120 °C

- A sealed system eliminates the need for liquid nitrogen cooling

- Enables cycling, MDSC®, controlled, and ballistic cooling experiments

Discovery Liquid Nitrogen Pump Accessory (LN Pump)

Image Credit: TA Instruments

For the Discovery DSC, the LN pump offers the best cooling performance and flexibility. The lowest operating temperature (down to -180 °C), maximum cooling rate capacity (up to 140 °C/min), quickest sub-ambient equilibration times, and a maximum temperature limit of 550 °C are all made possible by the Discovery DSC.

The LN pump efficiently uses liquid nitrogen when operating at ambient pressure, which lowers operating expenses. It comes with a 50 l Dewar with auto-fill capability, enabling uninterrupted DSC operation by automatically replenishing the LN Pump from a larger source, even when conducting a DSC experiment.

Tzero Pans

Image Credit: TA Instruments

The high-performance pans and lids from Tzero are made to maximize sample contact and pan flatness. The Tzero pans and lids offer the most direct and uniform heat flow path from the sample to the sensor when combined with the unmatched flatness and uniformity of the Fusion Cell™ sensor.

These pans effectively transfer heat to and from the entire sample because of their ability to accommodate a wide variety of sample forms and their lids’ ability to fit over irregular specimen tops.

With solid specimens, competitive pan designs with non-flat bases cannot establish the proper thermal contact. The Tzero pans, which are manufactured to incredibly strict tooling specifications and with cutting-edge technology, offer notable improvements in resolution and repeatability over any other pan design.

Tzero DSC Sample Encapsulation Press

With the Tzero press, sample encapsulation for conventional and hermetic sealing of a broad range of materials is performed with greater efficiency and convenience. Four die sets for Tzero aluminum and hermetic pans and lids are included in the press kit. For both Discovery TGA sealed pans and high-volume DSC pans, optional die sets are offered.

There is no need for any tools or adjustments because the die sets are magnetically attached. Every die set also has a color code that corresponds to the box that holds the standard or Tzero aluminum hermetic pans and lids that work with it.

Sample Cutting Kit

Image Credit: TA Instruments

Before being loaded into a DSC pan, samples for testing in the DSC usually need to be altered in some way due to their diverse shapes, sizes, and forms. The sample cutting kit comes with instruments that will make sample preparation easy for the highest level of repeatability and dependability in the outcomes.

To optimize sample-to-pan contact, a sample with a clean, flat surface can be obtained using a pliers-style sample cutter. With a 4 mm hole punch and hammer, film samples can be consistently cut to the right size for Tzero pans. This toolkit is intended to assist in ensuring that the flawlessly prepared sample enhances the high-level performance of the Tzero pans and the Fusion Cell.

Tzero® Powder Sample Preparation Kit

Image Credit: TA Instruments

The powder sample prep kit makes it quicker and simpler to load powder samples into Tzero pans. The kit includes a non-skid base and a three-part tool that is precisely machined from premium stainless steel. It is specifically designed to maximize the performance of Tzero Pans with powdered samples.

The Tzero pan is held in place and the bottom of the pan is supported and shielded by a carefully crafted recess in the lower tool. By mounting above the pan, the upper tool creates a funnel that funnels the sample into the pan’s center and prevents the pan’s exterior surfaces from becoming unintentionally contaminated.

To create a packed layer of powder and maintain the flatness of the Tzero pan’s bottom, the sample is firmly packed into the pan using a steel rod. Users can quickly and efficiently optimize the DSC readings of powdered samples by using this tool.

Software

TRIOS Software

The robust TRIOS software provides outstanding instrument control, data analysis, and reporting capabilities all in one integrated package. Unmatched versatility is provided by new capabilities including automated calibration routines, multiple calibration sets, real-time test method editing, and inter-laboratory data and test method exchange. Custom reporting and one-click analysis also boost productivity to new heights.

TRIOS Features and Benefits

- Optional TRIOS Guardian with electronic signatures for audit trail and data integrity

- Control multiple instruments with a single PC and software package

- Overlay and compare results across techniques including DSC, TGA, DMA, SDT, and rheometers

- Automated custom report generation including experimental details, data plots and tables, control charts, and analysis results

- Convenient data export to plain text, CSV, XML, Excel®, Word®, PowerPoint®, and image formats

- One-click analysis for increased productivity

Ease-of-Use

Calibration of the full differential scanning calculator line is made easy by TRIOS software. To match the experimental circumstances required for sample testing, users can effortlessly switch between numerous calibration data sets that are easily generated under varying experimental conditions (for example, different heating rates or gas selections).

Real-time signals and the status of ongoing experiments are easily accessible, and there is also the option to instantly change the running procedure. The industry’s highest degree of versatility is provided by TRIOS software.

Complete Data Record

All pertinent signals, active calibrations, and system settings are automatically saved by the sophisticated data collection system. This extensive collection of data is very helpful for developing methods, implementing procedures, and validating data.

Complete Data Analysis Capabilities

A comprehensive set of relevant tools are available for real-time data analysis, even during experiments. With a robust and adaptable feature set that is seamlessly integrated into TRIOS, users can get actionable insights into the behavior of their material.

All Standard DSC Analyses

- Easily import and export DSC data with TRIOS

- Glass transition, step change analysis

- Oxidative onset temperature

- Peak integration

- Purity

- Peak height and area

- 1st and 2nd derivatives

- Oxidative induction time

- Running integral and conversion

- Temperature at peak maximum

- Onset and endset analyses

Advanced Analysis Capabilities (Standard Features)

- Batch processing enables automated analysis, reporting, and control charting of large data sets

- Deconvolution of the total heat flow signal with MDSC® into reversing and non-reversing heat low signal

- Advanced custom analysis and control charts with user-defined variables and models