Deben, a leading provider of in-situ testing stages together with innovative accessories and components for electron microscopy, report on the use of the CT500 tensile stage in the X-ray microtomography laboratory at La Trobe University in Melbourne, Australia.

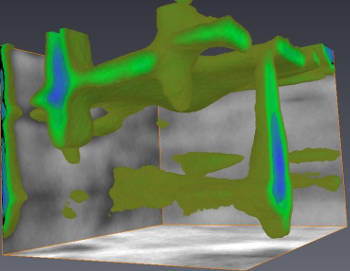

3D network of cracks and fibre/matrix: The sample has been loaded from bottom to top of the image; the blue areas show where the fibres have been removed. Minor cracking is observed perpendicular to the load direction.

3D network of cracks and fibre/matrix: The sample has been loaded from bottom to top of the image; the blue areas show where the fibres have been removed. Minor cracking is observed perpendicular to the load direction.

Dr Brian Abbey is an associate professor and ARC Future Fellow at the Australian Research Centre of Excellence in Advanced Molecular Imaging. (www.imagingcoe.org). His research group is interested in all types of imaging but X-rays are a major part of the work carried out. Three-dimensional, in-situ stress/strain analysis has important applications in both materials science and biology. The group purchased the Deben CT500 tensile stage with a view to exploring the evolution of samples subjected to stress at micron length scales and in three-dimensions.

Dr Benedicta Arhatari is the manager of the X-ray microtomography laboratory at La Trobe University. Since 2006, her laboratory has provided three-dimensional imaging capabilities for 27 external institutions made up of both Universities and companies; this adds up to a total of 48 separate users spending more than 600 hours on X-ray tomography measurements yearly.

The Deben CT500 tensile stage is used in conjunction with digital image correlation and microtomography to understand the stress-strain characteristics of advanced materials. Through collaborations with institutions including the Defence Science and Technology Organisation (DSTO), the Deben CT500 stage has enabled the study of effects such as delamination and crack propagation at micron length scales. The group are also exploring using the stage to examine the fracture mechanics of bone samples.

Having used the Deben in-situ stage combined with scanning electron microscopy (SEM) in the School of Engineering at Oxford University, Dr Abbey was already well-experienced with its use and was in full support of using the stage with the ZEISS Xradia X-ray tomography instrument. He finds the compact size and easy to use software of particular benefit. The fact that the Deben CT500 has also been used at the Australian synchrotron was also influential in the purchase decision.

One applications example was presented at the recent XRM meeting in Australia and combined the skills of researchers from La Trobe, Swinburne, DSTO and the Australian Synchrotron (where the measurements were made). The poster reported the computer tomography of ceramic matrix composites during mechanical loading.1 Ceramic fibres were pulled from the matrix and the results observed. The imaging results confirmed the expected toughening mechanism. As expected, the major crack did not propagate through the regions where the fibres were parallel to the load. Here the elastic strain energy was absorbed in creating the complex 3D network of cracks and fibre/matrix separation.

To obtain full details of the Deben applications and product portfolio, please visit www.deben.co.uk.

Reference

The computed tomography of ceramic matrix composites during mechanical loading, John Thornton et al, 12th International Conference on X-ray Microscopy, Melbourne, October 2014.

About Deben

Deben are a UK precision engineering company specialising in the field of in-situ tensile testing, motion control and specimen cooling for microscopy applications. Established in 1986 and named after a Suffolk river, Deben now operate from a large, modern business unit in Woolpit near Bury St. Edmunds in Suffolk. The product groups are motor control systems, in-situ micro-tensile stages, Peltier heating & cooling stages, detectors for SEMs and electro-static beam blankers. The company also makes custom and OEM versions of these products to specifically meet customer requirements.

Deben provide consultancy, design and prototype manufacturing services. In house facilities include SolidWorks and SolidEdge 3D CAD and COSMOS finite element analysis software, CNC machining, electronics design and manufacture and software design using Visual C++, Microsoft.net and DirectX. Utilising these resources and experience, Deben manufacture products for OEMs and end users in the UK and overseas.

Deben UK Ltd. is a subsidiary company of UK based Judges Scientific plc. For details on Deben and all its products & solutions, visit www.deben.co.uk.