May 24 2017

Trisha Andrew, Materials Scientist at the University of Massachusetts Amherst, proves that one day she will be able to produce a comfortable, lightweight jacket capable of generating the power to light up a jogger at night even though this entire concept may sound futuristic.

Recently, in a new paper, Andrew and her colleagues briefly explained how they have invented a method to apply pliable, breathable, metal-free electrodes to fabric and off-the-shelf clothing such that it feels good to the touch and also transports adequate electricity to power small electronics.

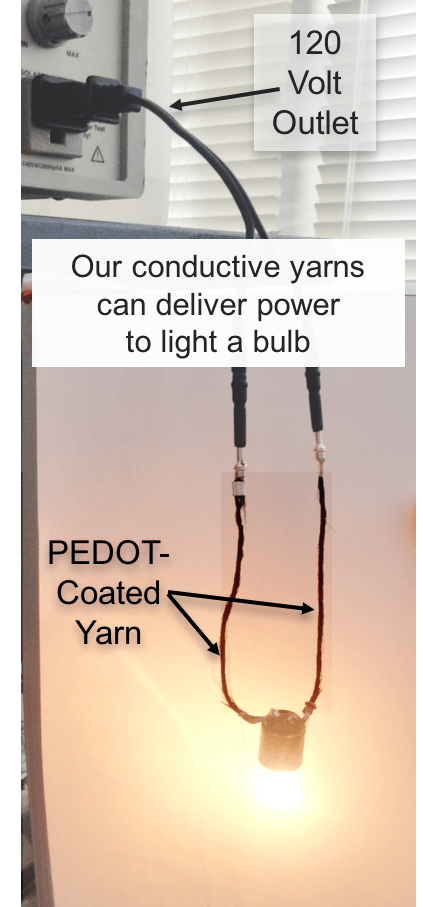

PEDOT-coated yarns that act as 'normal' wires transmit electricity from a wall outlet to an incandescent lightbulb. Materials Scientist Trisha Andrew at UMass Amherst and colleagues outline in a new paper how they have invented a way to apply breathable, pliable, metal-free electrodes to fabric and off-the-shelf clothing so it feels good to the touch and also transports electricity to power small electronics. Harvesting body motion energy generates power. CREDIT UMass Amherst.

PEDOT-coated yarns that act as 'normal' wires transmit electricity from a wall outlet to an incandescent lightbulb. Materials Scientist Trisha Andrew at UMass Amherst and colleagues outline in a new paper how they have invented a way to apply breathable, pliable, metal-free electrodes to fabric and off-the-shelf clothing so it feels good to the touch and also transports electricity to power small electronics. Harvesting body motion energy generates power. CREDIT UMass Amherst.

She says, “Our lab works on textile electronics. We aim to build up the materials science so you can give us any garment you want, any fabric, any weave type, and turn it into a conductor. Such conducting textiles can then be built up into sophisticated electronics. One such application is to harvest body motion energy and convert it into electricity in such a way that every time you move, it generates power.” Powering enhanced fabrics capable of monitoring health data remotely are vital to the military and greatly valued by the health care industry, she notes.

Andrew, who trained as an electrical engineer and polymer chemist, explains that producing small electric currents via relative movement of layers is known as triboelectric charging. Materials can become electrically charged as they develop friction by moving against a totally different material, similar to rubbing a comb on a sweater.

By sandwiching layers of differently materials between two conducting electrodes, a few microwatts of power can be generated when we move.

Trisha Andrew, Materials Scientist, University of Massachusetts Amherst

In the most recent early online edition of Advanced Functional Materials, she and Lu Shuai Zhang, a Postdoctoral Researcher in her lab, describe the vapor deposition method they use for coating fabrics with a conducting polymer, poly(3,4-ethylenedioxytiophene) also called PEDOT, in order to make plain-woven, conducting fabrics that are capable of being resistant to wear and stretching and remain firm even after washing and ironing. The thickest coating they put down is almost 500 nm, or about 1/10 the diameter of a strand of a human hair, which retains a fabric’s hand feel.

The Authors report outcomes of testing fabric stability, electrical conductivity, mechanical and chemical stability of PEDOT films and also textile parameter effects on conductivity for 14 fabrics, including five cottons with a variety of weaves, silk and linen from a craft store.

Our article describes the materials science needed to make these robust conductors. We show them to be stable to washing, rubbing, human sweat and a lot of wear and tear.

Trisha Andrew, Materials Scientist, University of Massachusetts Amherst

PEDOT coating did not alter the feel of any fabric as determined by touch with bare hands before and after coating. Coating did not increase fabric weight by more than 2%. The work was supported by The Air Force Office of Scientific Research.

Until recently, Andrew and Zhang point out, Textile Scientists have attempted to use vapor deposition due to technical issues and high cost of scaling up from the laboratory.

However, over the past 10 years, industries like mechanical component makers and carpet manufacturers have proved that the technology can be scaled up and remain cost-effective. The Researchers explain that their invention also helps to overcome the problem of power-generating electronics mounted on plastic or cladded, veneer-like fibers that make garments less flexible and/or heavier than off-the-shelf clothing, no matter how flexible or thin these device arrays are.

There is strong motivation to use something that is already familiar, such as cotton/silk thread, fabrics and clothes, and imperceptibly adapting it to a new technological application. This is a huge leap for consumer products, if you don’t have to convince people to wear something different than what they are already wearing.

Trisha Andrew, Materials Scientist, University of Massachusetts Amherst

Andrew adds that the test results were sometimes a surprise. “You’d be amazed how much stress your clothes go through until you try to make a coating that will survive a shirt being pulled over the head. The stress can be huge, up to a thousand newtons of force. For comparison, one footstep is equal to about 10 newtons, so it’s yanking hard. If your coating is not stable, a single pull like that will flake it all off. That’s why we had to show that we could bend it, rub it and torture it. That is a very powerful requirement to move forward.”

Andrew is Director of wearable electronics at the Center for Personalized Health Monitoring in UMass Amherst’s Institute of Applied Life Sciences (IALS). Since the fundamental work reported this month has been completed, her lab has also developed a wearable heart rate monitor with an off-the-shelf fitness bra. Eight monitoring electrodes were added to this bra. Her lab also plans to test this bra with volunteers on a treadmill at the IALS human movement facility.

Andrew explains that a hospital heart rate monitor comprises of 12 electrodes, while the currently popular wrist-worn fitness devices have one, which indeed makes them prone to false positives. In the future, they will be testing a bra with eight electrodes, alone and worn with leggings that add four more electrodes, against a control in order to observe if sensors can match the sensitivity and accuracy of what a hospital can do. As noted by the Authors in their paper, body-worn, flexible electronics represent a frontier of human interface devices that bring about the possibility of improved performance and physiological monitoring.

For the future, Andrew says, “We’re working on taking any garment you give us and turning it into a solar cell so that as you are walking around the sunlight that hits your clothes can be stored in a battery or be plugged in to power a small electronic device.”

Andrew and Zhang believe their vapor coating is capable of sticking to fabrics by a process known as surface grafting, which takes advantage of free bonds hanging on the surface chemically bonding to one end of the polymer coating, however they are yet to investigate this in great detail.