Enhanced specular reflectors (ESR) like 3M Vikuiti™ are highly reflective, mirror-like optical enhancement films that are mainly used in light recycling liquid crystal display (LCD) applications for high efficiency brightness enhancement. The ESR multilayer polymeric interference mirrors were developed in the late 1960's (Figure 1). These films are ultra-thin, flexible and non-metallic, and use multi-layer polymer technology. They are used in a wide range of devices and configurations, such as phones, monitors and televisions, thanks to its thin film design. Light recycling improves the displays’ brightness, and at the same time, saves significant amounts of energy.

Figure 1. A rolled sheet of enhanced specular reflector (ESR) polymer film.

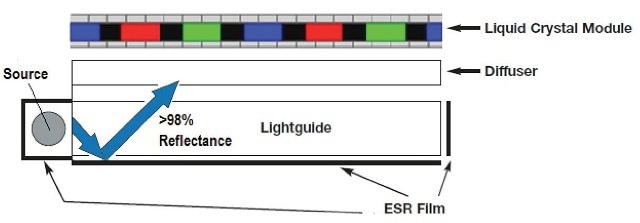

ESR films typically reflect >98% of light. This means more light can be recycled and reflected to render a brighter display, and the amount of energy required to power an LCD display is also significantly reduced. The increased brightness of the display results in a wider viewing angle. Figure 2 shows a standard LCD display diagram, demonstrating the area where the ESR film is applied. Almost all LCD displays feature ESR films. These films can also be used to control and optimize architectural lighting, solar lighting like tubular daylighting devices (TDDs) depicted in Figure 3, and automotive lighting.

Figure 2. Diagram of a simplified LCD panel illustrating where ESR film is typically used.

Figure 3. Example of Tubular daylighting devices (TDDs) which capture sunlight using a rooftop dome, and then transfer it indoors through a reflective tube that runs from the roof to the ceiling. For most commercial TDDs, ESR film is used in the interior of the light transfer tube to achieve high specular reflectivity (up to 99.7 % reflective in the visible spectrum) thereby delivering maximum visible light.

In the case of commercial TDDs, high specular reflectivity is achieved by using the ESR film in the interior part of the light transfer tube. This provides the highest visible light with reduced solar heat gain. The light output of a TDD is high, providing the same amount of light you would expect from a skylight many times its size. TDDs conserve energy and reduce environmental pollution by allowing electric lights to be switched off during the day.

The Measurement Challenge

Commercially available spectrophotometers make it difficult to validate the performance of ESR films. Since such films are designed to achieve an ultra-high reflectance in the visible spectral range, angle of incidence, and under different states of light polarization, a combination of absolute variable angle reflectance accessory and an automated polarization accessory should be used to determine the ESR films. Since these films are very thin, users would find it difficult to properly place the ESR films in the reflectance sample fixture. This technique is required to ensure that the film’s surface continues to remain flat to the incident beam.

Equipped with the universal reflectance accessory (URA) , the PerkinElmer LAMBDA™ 1050 uses 3D (three detector) technology. This advanced research UV/Vis/NIR spectrometer is suitable for investigating the ESR films’ properties. Figure 4 shows an image of a LAMBDA 1050 equipped with the URA accessory.

Figure 4. LAMBDA 1050 with universal reflectance accessory (URA).

Holographic gratings in the form of a Littrow double monochromator design are included in the LAMBDA™ 1050 system that ensure that stray radiation level is specified at less than 0.00007%T in the UV/Vis range. PerkinElmer developed the unique URA accessory for highly precise absolute specular reflectance. Providing angles from 0° to 70°, the URA is motorized in increments of 0.5° and lacks a sample holder. This means, samples can be placed flat on a measuring plate over the top of the accessory. Here, the internal optics directs the beam towards a measurement port (Figure 5).

Figure 5. Sample measurement surface of the URA accessory. Using internal kinematic optics the light beam is directed to the measurement port at the center. Samples lay flat covering the port.

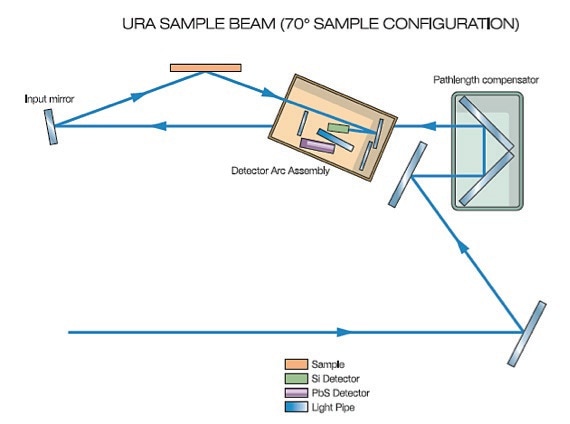

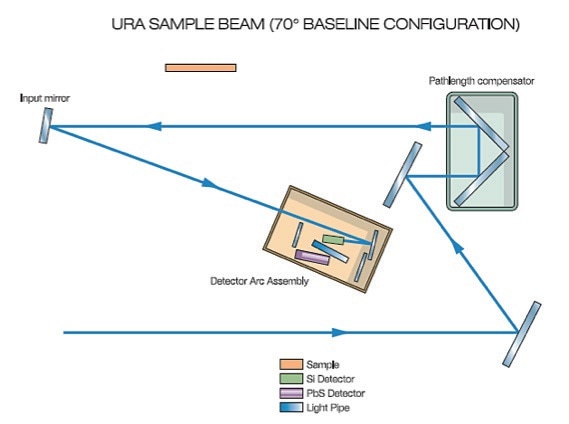

The accessory has its own kinematic detector module and pathlength compensator, maintaining identical pathlengths and angle of incidences between the background and the sample measurement. URA-based measurements include a sample measurement, which involves another reflection at the sample, and a baseline measurement. While switching between sample and baseline configurations, a single mirror is rotated and the detector assembly is automatically translated. This is illustrated in the case of measurement at 70° incidence, as shown in Figure 6.

Figure 6. Illustrated are the URA sample and baseline measurement configurations at 70°.

In order to guide the beam onto the measurement sample, the input mirror rotates and the detector assembly is simultaneously translated to sustain the same association with the input beam. The overall optical path continues to remain the same so that the ratio of both measurements provides the sample’s reflectance. One way to acquire precise specular reflectance measurements is to place the samples flat on the URA’s measurement port. This is because the thin films measure just 65µm, making these films very difficult to measure in a vertical sample holder in a conventional absolute specular reflectance accessory.

If the ESR films are properly placed in a sample holder meant for filters and glass, it is less likely that the film will remain flat to the incident beam. If the thin ESR film fails to remain flat to the incident beam, the measurement results for any angle of incidence and polarization state will be in error.

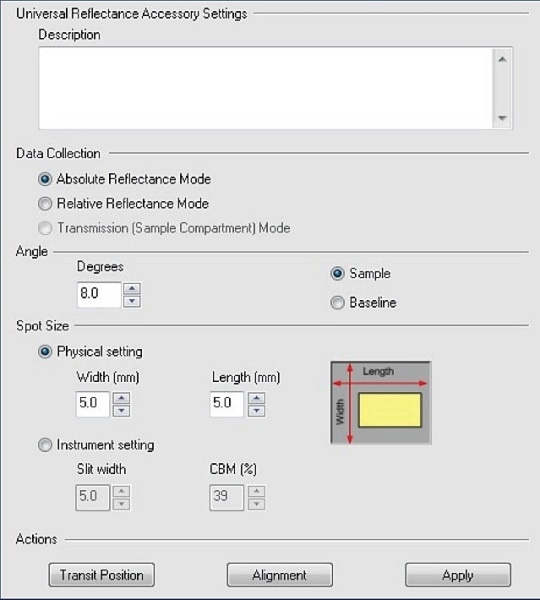

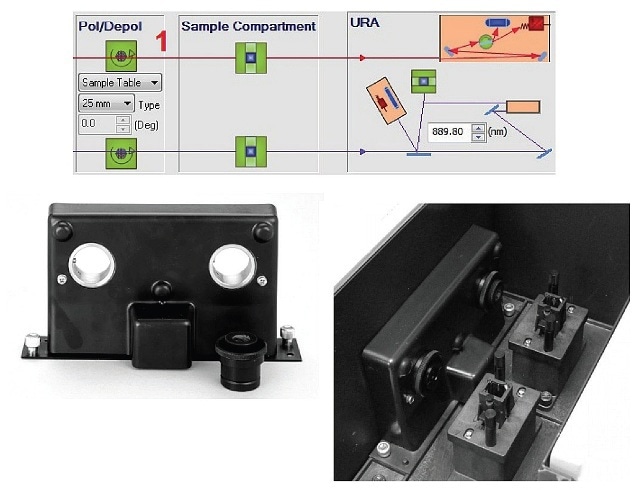

For the LAMBDA series, the UVWinlab™ V6 software is integrated with URA control that allows users to determine the measurement spot size and the sequence of angles. Once a method is created, the measurements proceed automatically. Figure 7 shows the URA accessory settings in the UVWinlab software. On this page, either a measurement angle can be added or a series of measurement angles can be introduced within the sample table. It is possible to control the measurement port beam spot size. Users can also leverage the URA accessory to alter the beam spot size on the sample, in the range of 0.1 x 0.1 to 5.0 x 5.0mm in increments of 0.1mm. With this range, small and complex samples can be easily accommodated.

Figure 7. Shown is the Universal Reflectance Accessory settings page of UVWinlab. In addition to the measurement angle, the beam spot size can be finely adjusted.

Besides URA installation, the sample compartment region of the LAMBDA 1050 is also equipped with an automated polarization drive accessory, as shown in Figure 8.

Figure 8. Polarizer drive accessory (left) and drive accessory mounted in the LAMBDA 1050 sample compartment (right). With this motorized accessory the polarization angles can be programmed automatically.

This polarizer drive, when fitted with a Glan-Taylor or Glan- Thompson calcite polarization crystal, allows the polarization state of the sample beam to be modified in the range of 0-360 degrees. In the UVWinlab method, if the polarizer is set to “Sample Table”, labeled 1 in Figure 8. The polarization angles can be conveniently entered in the sample table sequence, allowing automated operation.

Measurement of ESR Films Using the LAMBDA 1050

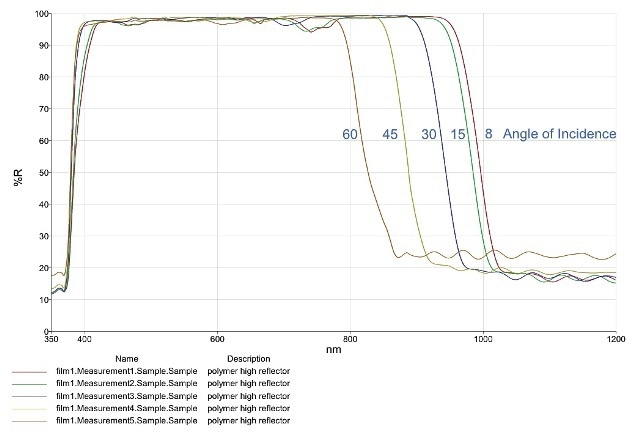

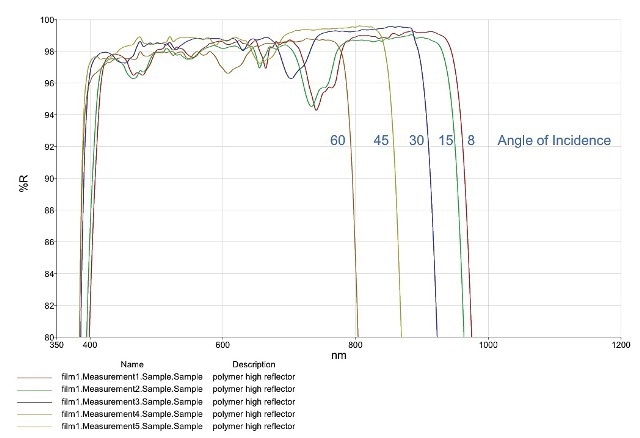

The UVWinlab V6 is user-friendly software that is mainly used for operating the LAMBDA 1050 series. It is compatible with Windows® 8 and utilizes an advanced work- flow design. After defining the sample table, the URA-based measurements at the angles entered will continue automatically. For each angle, the background corrections are obtained and stored automatically. The superimposed data acquired from these measurements is illustrated in Figure 9, and a spectral expansion is shown in Figure 10.

Figure 9. Absolute reflectance spectra of an ESR film sample collected with the LAMBDA 1050 and URA accessory from 1200 to 350 nm. URA angles of 8, 15, 30, 45, and 60 degrees were used, with a 4.0 x 4.0 mm beam spot size, and with depolarized light.

Figure 10. Expanded view of the spectra shown in Figure 9.

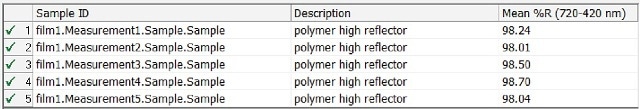

In this case, the UVWinlab V6 software was used to measure the mean reflectance in the visible range using a data processing equation and was measured to be 98% R or greater, as shown in Figure 11. However, it should be noted that the reflectivity values would be considerably affected by small particulates on the surface of the film as well as slight amounts of surface abrasion of the ESR film. The URA accessory will not scatter, but collects specular reflection. If the curves are reduced while approaching the blue region, this could be attributed to scatter loss.

Figure 11. Calculated mean value displayed in table

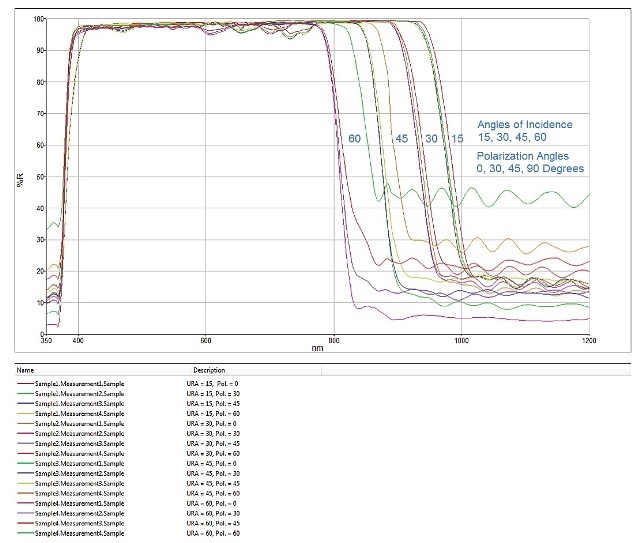

In the next measurement series of an ESR film sample, the URA accessory and the LAMBDA 1050 system equipped with a Glan-Taylor calcite crystal and polarizer drive were used to study the impact of the incident angle and polarized light. Using the URA accessory, the ESR film sample was scanned between 1200 and 350nm at four angles: 15, 30, 45, and 60° with polarization angles of 0, 30, 45, and 90°. Hypothetically, if the ESR film is operating suitably, there would be high visible reflectivity, irrespective of the state of polarization or angle of incidence. Figure 12 shows the data acquired from the second measurement series.

Figure 12. Shown here are the URA measurements of the ESR film sample at angles of incidence of 15, 30, 45, and 60 degrees. Each URA angle is measured with polarization angles of 0, 30, 45, and 90 degrees. This illustrates that the ESR film sample performs as designed, with reflectivity in the visible remaining high regardless of angle of incidence and polarization state.

Conclusion

Featuring the automated polarizer drive and URA accessory, the LAMBDA 1050 has proven to be an effective tool for studying the performance properties of ESR films. In spite of the polarization state and angle of incidence, the design of the ESR films provides excellent reflectivity in the visible range. In order to realize precise specular reflectance measurement of ESR films, an absolute variable angle specular reflectance accessory is required, and to validate the polarization response a polarizer accessory is needed.

As described above, the LAMBDA 950-1050, equipped with the motorized polarizer drive accessory and the absolute variable angle motorized URA accessory enables automated evaluation of the performance of the ESR films. Precise reflectivity measurements of these films are also ensured, thanks to the unique design of the URA accessory.

This information has been sourced, reviewed and adapted from materials provided by PerkinElmer.

For more information on this source, please visit PerkinElmer.