Reviewed by Lexie CornerJul 8 2025

Scientists at the U.S. Department of Energy’s (DOE) Argonne National Laboratory have developed a new membrane technology that efficiently separates lithium from water. This could help address increasing demand and potential supply chain challenges.

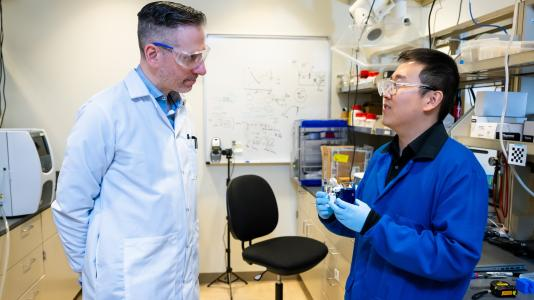

An H-shaped cell is used to study how the membrane transports materials. One side contains a saltwater mixture (blue liquid), while the other side shows the result after separation through the membrane (clear liquid). From left to right: Seth Darling and Yining Liu. Image credit: Argonne National Laboratory.

An H-shaped cell is used to study how the membrane transports materials. One side contains a saltwater mixture (blue liquid), while the other side shows the result after separation through the membrane (clear liquid). From left to right: Seth Darling and Yining Liu. Image credit: Argonne National Laboratory.

Lithium is the lightest metal on the periodic table and plays a critical role in modern technology. Its low weight and high energy density make it useful in electric vehicles, cell phones, laptops, and military equipment, where minimizing weight is important. As demand grows, concerns about supply and reliability are increasing.

Several members of the research team also hold appointments at the University of Chicago’s Pritzker School of Molecular Engineering (PME).

The new membrane we have developed offers a potential low-cost and abundant alternative for lithium extraction here at home.

Seth Darling, Chief Science and Technology Officer, Advanced Energy Technologies, Argonne National Laboratory

Darling is also the director of Argonne's Advanced Materials for Energy-Water Systems (AMEWS) Energy Frontier Research Center. He is a senior scientist at the Pritzker School of Molecular Engineering (PME).

Currently, the majority of the world's lithium originates from hard-rock mining and salt lakes in only a few countries, making supply chains vulnerable to disruption. However, the vast majority of lithium on Earth is dissolved in saltwater and underground saltwater resources.

What is the problem? Extracting it from these unusual sources has proven excessively costly, energy-intensive, and inefficient. Traditional techniques struggle to isolate lithium from abundant elements such as sodium and magnesium.

In salt water, lithium and other elements exist as cations - atoms with a positive charge due to the loss of electrons. Effective lithium extraction depends on removing other cations based on their size and charge.

The new membrane offers a lower-cost and practical option. It is made from vermiculite, a naturally occurring clay that costs about $350 per ton. Researchers developed a process to separate vermiculite into very thin layers - just one billionth of a meter thick - and rearranged them into a stacked structure. Because these layers are so thin, they are classified as two-dimensional (2D).

However, the untreated clay layers break down in water within 30 minutes. This happens because the clay strongly attracts water.

To prevent this, the team added tiny aluminum oxide pillars between the layers. This structure resembles a multi-level parking garage under construction, with solid pillars supporting each layer. The pillars stabilize the membrane by neutralizing its negative surface charge. This step is key to improving membrane durability.

Next, the researchers added sodium cations. These gathered around the aluminum oxide pillars and changed the membrane’s surface charge from neutral to positive. In water, both magnesium and lithium carry a positive charge. Magnesium has a charge of +2, while lithium has a charge of +1. The positively charged membrane repels the more highly charged magnesium ions more strongly than lithium. This allows the membrane to selectively retain lithium while excluding magnesium.

To improve selectivity further, the team added more sodium ions. This reduced the size of the membrane’s pores. As a result, the membrane captures larger lithium ions while allowing smaller ions like sodium and potassium to pass through.

Filtering by both ion size and charge, our membrane can pull lithium out of water with much greater efficiency. Such a membrane could reduce our dependence on foreign suppliers and open the door to new lithium reserves in places we never considered.

Yining Liu, Study First Author and Ph.D. Candidate, University of Chicago

The researchers say this approach may also be used to recover other valuable metals, such as nickel, cobalt, and rare earth elements. It could also help remove harmful pollutants from water.

“There are many types of this clay material. We’re exploring how it might help collect critical elements from seawater and salt lake brines or even help clean up our drinking water,” added Liu.

This type of innovation may support both modern technologies and future infrastructure, especially as reliable access to key materials and clean water becomes increasingly important.

The study was funded by AMEWS, an Energy Frontier Research Center supported by the DOE Office of Basic Energy Sciences.

In addition to Darling and Liu, Argonne authors include Yuqin Wang, Bratin Sengupta, Omar Kazi, Alex B. F. Martinson, and Jeffrey W. Elam. Liu, Wang, Kazi, Elam, and Darling also hold joint appointments at PME.

Journal Reference:

Liu, Y., et al. (2025) Pillared Laminar Vermiculite Membranes with Tunable Monovalent and Multivalent Ion Selectivity. Advanced Materials. doi.org/10.1002/adma.202417994.