International Syalons offers extremely complex geometry components in silicon nitride-based technical ceramic grades Syalon 101 and 050 via lithographic additive manufacturing technology (L-AMT).

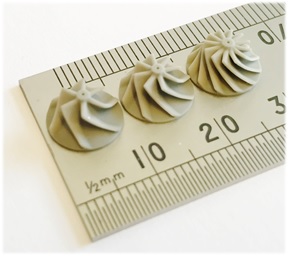

3D-printed Syalon impellers. Image Credit: International Syalons

The recent EU funded Horizon 2020 Tomax project brought together leading industrial additive manufacturing experts from across Europe in the fields of high-performance light-sources, photopolymers, ceramics, life cycle analysis, system integration, software development, mechanical engineering, industrial exploitation, and end-user applications. The project surpassed expectations and achieved its goals of developing high throughput 3D-printers with excellent efficiency for some of the most challenging advanced ceramics.

Following the Tomax project, and by utilising the knowledge and expertise of global leaders in ceramic additive manufacturing, International Syalons are now able to offer novel complex geometry components in Syalon 101 and 050 grades with outstanding precision and surface finish qualities.

Lithographic Additive Manufacturing Technology (L-AMT)

While 3D-printing of metal and polymer components is well established, it is still an emerging technology for technical ceramics. Lithographic additive manufacturing technology (L-AMT) is now mature enough to enable ceramics manufacturers such as International Syalons to offer defect-free complex 3D-printed components with thermomechanical properties equal to those produced by conventional methods such as pressing, casting, or extrusion.

The L-AMT process builds ceramic green bodies by taking a suspension of ceramic particles in a solvent containing a photocurable resin, and cures only the desired cross-section as the component ‘grows’ out from the suspension layer by layer. Typically, layers can be as thin as 10 µm, which requires great mechanical and light source power control of the printing system but is necessary for building accurate components with high green density.

Once the green body has been formed, the post-printing thermal processing required to achieve full density is like that of traditionally formed sialon ceramics; high temperature sintering under carefully controlled conditions in a nitrogen atmosphere.

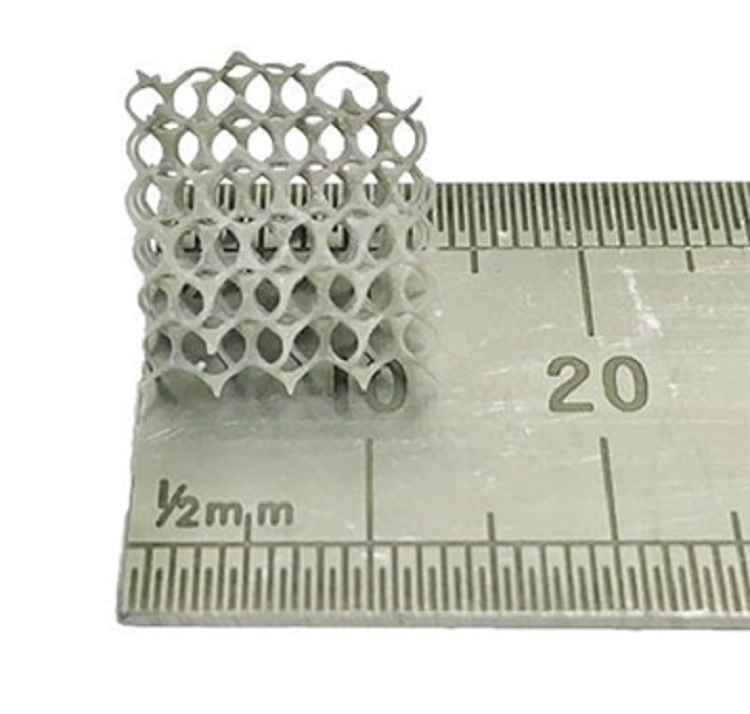

Although the printing process might be considered slow and costly in comparison to traditional ceramic forming methods, it is the only method available which can form some extremely complex geometries, such as the Syalon 101 gyroid shown below. A further advantage is for prototyping or small batch production cases, where the slow process or cost of new technology negates the high cost of tooling which is only beneficial for high volume production runs.

3D-printed Syalon 101 gyroid design. Image Credit: International Syalons

Properties of L-AMT Syalon

The table below compares the mechanical properties of 3D-printed with conventionally iso-pressed and green machined Syalon 101.

|

Material

|

Density (g/cc)

|

Hardness (Hv10)

|

3-point Modulus of Rupture (MPa)

|

|

L-AMT Syalon 101

|

3.25

|

1500.5

|

951.3

|

|

Iso-pressed Syalon 101

|

3.25

|

1500.0

|

945.0

|

The following video displays the superior thermal shock resistance of a 3D-printed Syalon 050 impeller. Here, the impeller remains intact after being quenched from 800°C into water at room temperature.

** Thermal shock test of a Syalon impeller 3D printed using L-AMT **

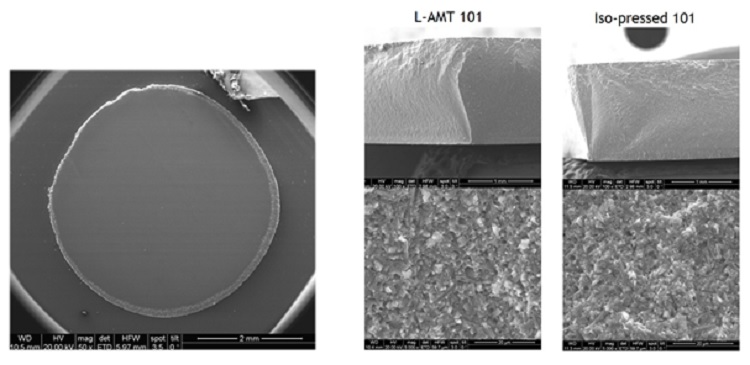

Further analysis of 3D-printed Syalon 101 materials has shown no adverse microstructure when comparing fracture surfaces with iso-pressed material, showing zero porosity or printing artefacts such as distinguishable layers from the printing build process, as shown in the images below.

SEM image showing a cross-section of L-AMT Syalon 101, and fracture surface comparison for L-AMT and conventionally manufactured Syalon 101. Image Credit: International Syalons

Conclusion

International Syalons continue to work in close cooperation with end-users to develop complex new parts for applications where L-AMT is the only method of fabrication and Syalon is the ideal material.

Novel applications where L-AMT Syalon can be utilised include advanced aerospace, defence, and automotive industries, as well as biomedical, oil and gas, and other power generation applications. Successful case studies include complex high surface area catalyst structures, complex nozzles for novel extrusion or spray applications, and high temperature wear resistant switch components.

Examples of L-AMT Syalon Components. Image Credit: International Syalons

International Syalons was the first company to patent and develop sialon ceramics for industrial markets, and we are dedicated to continued innovation in the field of technical ceramics. We provide an extensive range of engineered ceramics products, with L-AMT Syalon 101 representing the most cutting-edge sialon manufacturing capacity currently available.

If you would like any more information about 3D-printing of technical ceramics, please do not hesitate to contact us.