How soon a material wears out can be instrumental in its performance and reliability over the product’s lifetime. The surface aesthetics such as how the material looks and feels to touch will also be influenced by the wear resistance of the material. Here a nanoindenter is used to shed some information on how to measure specific surface wear for Polymethyl methacrylate or PMMA. In the experiment, it is investigated how a specific wear rate can be calculated using scratch testing. The specific wear rate is a function of scratch depth.

Materials and Methods

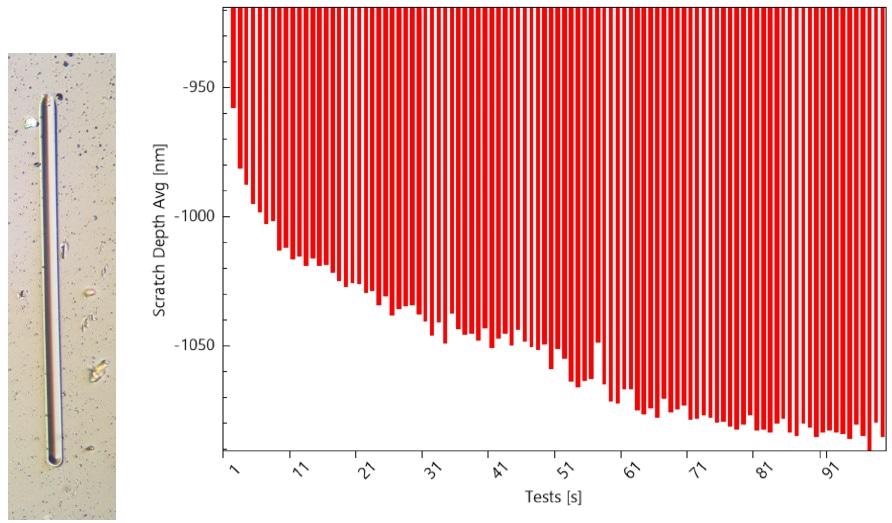

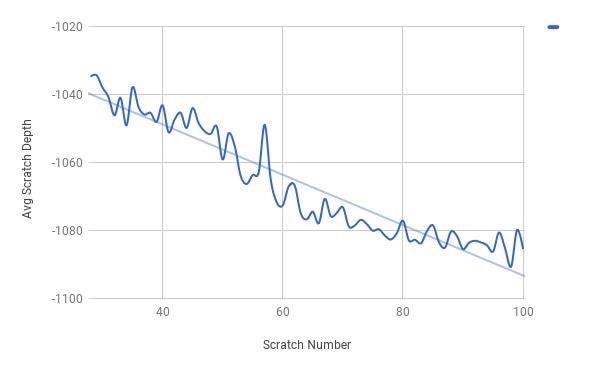

The testing implement used for the scratch experiments is a Nanomechnanics, Inc. iNano Nanoindenter with a diamond conical indenter. The sample tested was bulk PMMA mounted on an aluminum puck. The nanoindenter caused a constant load scratch of 5 mN on a scratch length of about 200 um. The nanoindenter began scratching the same area for a 100 times. The scratching was done at a velocity of 10 um/s. Average scratch depth was calculated by measuring the results of the scratches which varied in depth from 10% to 90% of the scratch length in the 100 scratches performed during the testing.

Figure 1. (a) Resulting scratch after 100 passes at 5 mN; (b) Average depth of the scratch vs. test number on PMMA at 5 mN.

Wear Rate and Volume

The specific wear rate for any material can be calculated using the measured average depth during each scratch. Wear rate, k, has most physical relevance when reported as volume loss per unit normal force per unit sliding distance  . This shows the loss of material occurred by the wearing.

. This shows the loss of material occurred by the wearing.

Using a spherical indenter tip allows volume loss to be found by calculating the volume at a given depth of a sphere, V =  y2,(1.5D − y) where D is the diameter and y is the depth of the sphere in millimeters.

y2,(1.5D − y) where D is the diameter and y is the depth of the sphere in millimeters.

Wear rate is then calculated k =  as where P is the normal force (in Newtons) and L is sliding distance (in meters). Values of k vary from 10-2 to 10-7, with anything typically above 10-5 being considered not very resistant to wear.

as where P is the normal force (in Newtons) and L is sliding distance (in meters). Values of k vary from 10-2 to 10-7, with anything typically above 10-5 being considered not very resistant to wear.

Specific Wear Rate

The specific wear rate for the PMMA tested during the experiment was assumed to be between 10-4 and 10-5 (mm3/N-m). This assumption was based on the values known for common polymeric materials. The specific wear rate of PMMA was calculated to be approximately 1.4 ∙ 10-5 (mm3/N-m) in the experiment process. This is aligned with the assumption and was an expected value proving that the testing was successful.

This number corresponds well with the expected values from the literature.

References

"Glossary of Terms," in ASM Handbook, Vol. 18, Friction, Lubrication and Wear Technology, USA, ASM International, 1992, p. 21.

J. F. Archard, "Single Contacts and Multiple Encounters," Journal of Applied Physics, vol. 32, no. 8, pp. 1420-1425, 1961.

G. W. Stachowiak and A. W. Batchelor, Engineering Tribology, Oxford: Elsevier, 2005.

This information has been sourced, reviewed and adapted from materials provided by Nanomechanics, Inc., a KLA-Tencor company.

For more information on this source, please visit KLA.