Some commonly used materials in analytical instruments were compared to see how fast reactive and sticky compounds moved through ¼” and 1/8” tubes.

The materials tested were PTFE, 316L stainless steel, and SilcoNert® 2000 (a CVD silicon coating applied to 316L stainless steel).

Sensors Inc. set up the test conditions; 3-m long ¼” and 1/8” tubes, and the test chemicals ammonia. They tested for uptake and release of 11.5 ppm ammonia through a sampling system at a flow rate of 10 L/h at room temperature.

The uptake test measures the time taken to wet the sample path length. If the tube surface absorbs or hinders flow, it will take longer for the liquid to flow through. The best material will show no delay.

Benefits

- Sample moves quickly through detector, making readings faster and provides optimum process control

- No sample loss on inert surfaces

- Fast release: quick return to baseline with no noise

- Eliminates cross contamination or carryover

- Sample “memory” by presence of residues will be prevented

- Shortest possible cycle time

Results

SilcoNert® 2000-coated 316L stainless steel showed no significant ammonia adsorption and took less than half the time of the other materials.

| Sampling Line Material |

Average Rise Time

(average of 5 replicates) |

| PTFE |

16.2 seconds |

| SS316L |

17.0 seconds |

| SilcoNert® 2000 coated 316L |

8.4 seconds |

The next table shows the results of the time it takes to purge the system of ammonia.

| Sampling Line Material |

Average Fall Time

(average of 5 replicates) |

| None (intrinsic analyzer response) |

6.0 seconds |

| PTFE |

18.2 seconds |

| SS316L |

33.0 seconds |

| SilcoNert® 2000 coated SS316L |

9.4 seconds |

SilcoNert 2000 shows both improved uptake and release.

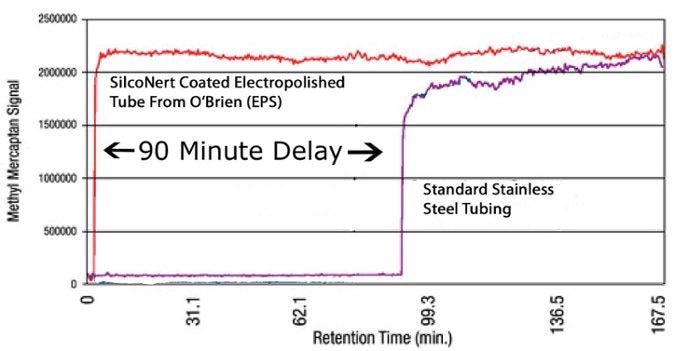

Sulfur Adsorption Testing

A trace amount of methyl mercaptan was run through 100 ft, 1/8” diameter tubes of stainless steel and SilcoNert coated electropolished stainless steel. It took 90 minutes for the sample to come out from the stainless steel tube; a very long time that can impact processes and may even have compliance issues. In contrast, it took only 3 minutes for the sample to come out of the SilcoNert-coated tube.

Why Speed Matters?

Minimal adsorption or contamination means fast, reliable results, leading to better process control, improved monitoring, and getting accurate data for regulatory compliance. In the end, this saves a lot of money.

This information has been sourced, reviewed and adapted from materials provided by SilcoTek.

For more information on this source, please visit SilcoTek.