The high-performance refractory ceramic—silicon nitride (Si3N4)—can occur in three different crystallographic phases (α, β, and γ), each exhibiting separate thermodynamic specifications. Each of these material phases is appropriate for rigorous working conditions. In some of the most demanding industrial sectors across the world, silicon nitride has been used for producing high-temperature components.

SiAlON ceramics were designed as a direct solution to the problematic and costly traditional sintering techniques associated with sintering silicon nitride materials to full density.

The Discovery of SiAlON Ceramics

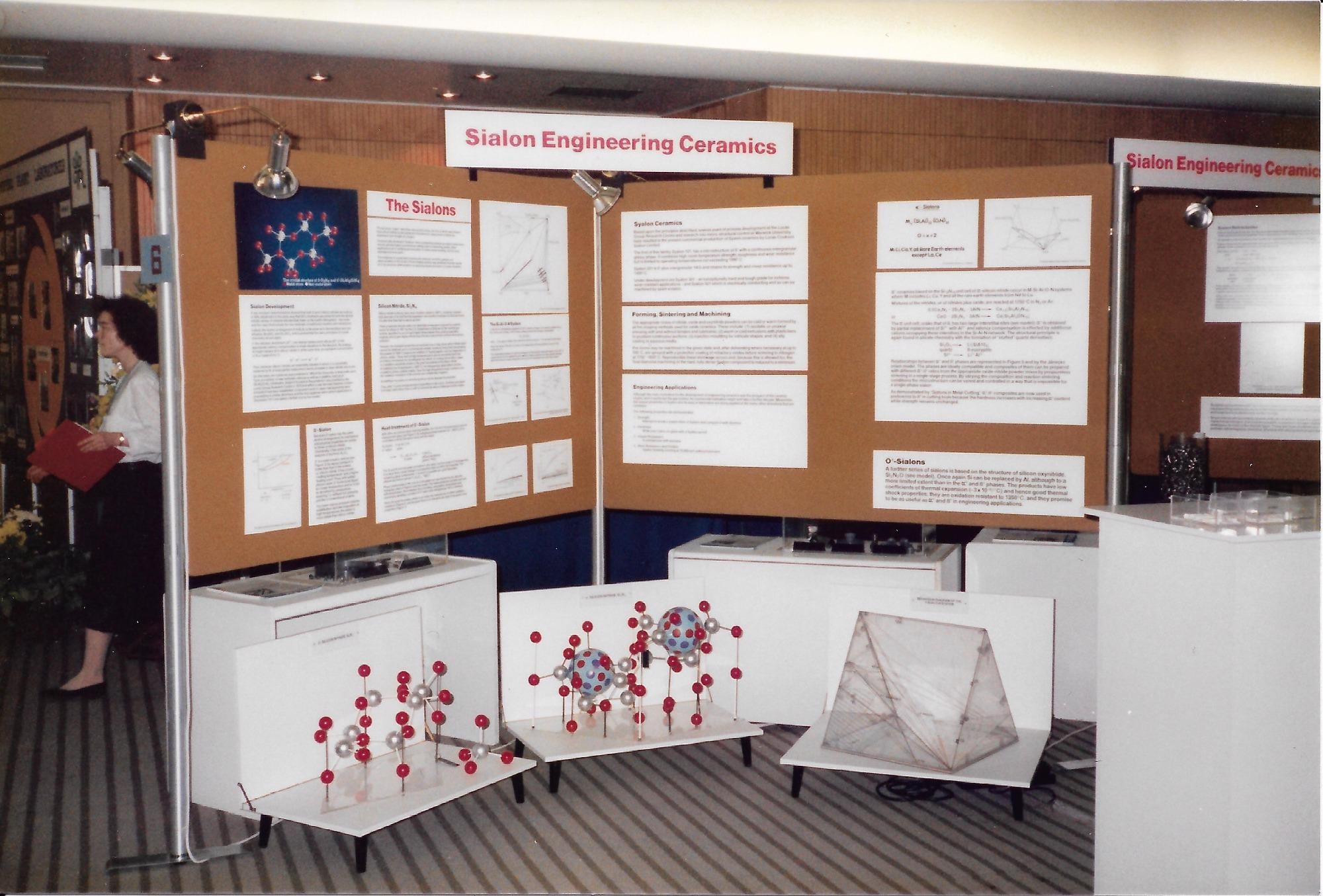

Autonomous studies in Japan and at Newcastle University in the UK were performed in the 1970s, which produced encouraging results with the formation of new arrangements of silicon (Si), aluminium (Al), oxygen (O), and nitrogen (N), which can be thought of as ‘alloys’ of silicon nitride. The SiAlON ceramics, thus obtained, had several similarities including isostructural arrangements with the three phases of silicon nitride.

The first economically viable SiAlON was isostructural with β-silicon nitride. Nitrogen atoms were replaced with oxygen and silicon atoms were mutually substituted for aluminium, causing a very minimal change to the basic structural integrity of silicon-nitride bonds that are arranged in high-strength tetrahedra. Soon after this discovery, the β-SiAlON grade Syalon 101 was introduced for industrial and commercial use, offering a functional and economical alternative to well-known silicon nitride.

Later, α- and α:β-SiAlON composite ceramics were discovered, wherein the former being isostructural with α-silicon nitride and exhibiting a physiochemical stacking arrangement was different from the well-known SiAlONs. While changing the silicon’s tetrahedral structure in the α-phase material resulted in significant reduction in ductility, it led to a SiAlON grade with better hardness over β-SiAlONs. Mixed α:β-SiAlON grades, for example, Syalon 050 were produced to offer an ideal intersection of hardness, toughness and strength for improved wear abilities.

Innovations in SiAlON Ceramics

From the time of their inception over four decades ago, SiAlON ceramics have turned out to be one of the top engineered materials for use in extreme operating conditions. Molten metal heater and riser tubes, extrusion dies and thermocouple protection sheaths are normally fabricated using β- and α:β-SiAlON ceramics. The capacities of these materials for industrial and commercial applications are further being improved through ongoing innovations.

Titanium nitride was used to develop the β-phase composite Syalon 501 in order to change the SiAlONs’ insulating properties and allow electro-discharge machining of the material. This leads to a slight reduction in physio-mechanical properties, while allowing profiling abilities that are not possible with the traditional material, aiding the fabrication of more intricate ceramic profiles than ever before.

This development is slowly being overtaken by the initiation of additive manufacturing, which represents considerable potential for 3D printing ceramic materials with near-identical physical characteristics to the same materials made by iso-static processing. At present, Syalon 101 can be printed into exclusive profiles of increasingly small sizes to aid traditional manufacturing processes with innovative material arrangements.

SiAlON Ceramics from International Syalons

International Syalons has been inherently involved in the history of SiAlON ceramics from the time they were initially discovered in the 1970s. The company is committed to continuing material advancements to offer a widespread alternative to costly material problems.

Introducing Additive Manufacturing for Silicon Nitride Ceramics

Additive manufacturing (AM), also called 3D printing, is a method through which complex geometries are designed and manufactured from an infinite range of materials using state-of-the-art deposition techniques. The process involved depositing minimal quantities of a specified material into pre-set channels to form tiny, complex components – as against traditional production methods which subtract materials through pressing and extrusion, or milling and machining.

Since the 1980s, AM methods have been progressing with the development of bioprinters and the broader commercial availability of basic 3D printers, which have supported the development of increasingly complex shapes from a wide range of materials. From an industrial viewpoint, it represented an immense potential for the formation of intricate refractory components using silicon nitride ceramics.

The Challenges of Complex Ceramic Shapes

Traditional manufacturing methods for complex silicon nitride ceramic shapes including spherical high-density green bodies have produced costly and challenging results. This is mainly due to the extended formation time, poor sintering output and costly moulds, which have lowered the commercial viability of producing intricate refractory shapes.

Conversely, with the recent completion of ToMax—a European Commission-funded Horizon 2020 project—of which International Syalons were consortium members, International Syalons has invested considerably in lithographic additive manufacturing technology (L-AMT) to fabricate SiAlON ceramics into complex, millimetre-sized shapes, that can meet the improved thermal properties of the traditionally produced material.

Successful AM of Silicon Nitride Ceramics

At present, international Syalons has effectively produced silicon nitride ceramics by AM processes, accomplishing near-identical high strength and thermal properties as materials manufactured through iso-static pressing.

| Material |

Density (g/cc) |

Hardness (HV10) |

Ave Biaxial Stress (MPa) |

Equivalent 3pt MOR (MPa) |

Weibull Modulus |

| L-AMT Syalon 101 |

3.25 |

1500.5 |

763.8 |

951.29 |

6.7 |

| Iso-static pressed Syalon 101 |

3.25 |

1500.0 |

770.0 |

945.0 |

11 |

However, this technology has not been developed enough to substitute traditional manufacturing techniques for silicon nitride ceramics.

AM of silicon nitride ceramics can produce components of previously impossible sizes and shapes, with suitability for prototype technologies or high-technology applications. Neither was it expected to substitute the established extensive production of larger components nor was it designed to. It can assist conventional manufacturing processes by facilitating previously unexpected designs.

3D-Printed Silicon Nitride Ceramics from International Syalons

As the first company to patent and produce sialon ceramics for industrial markets, International Syalons is dedicated to innovation in the cutting-edge ceramic industry. The company offers a variety of advanced ceramic materials, comprising of five separate grades of silicon nitrides appropriate for a wide range of applications – and its AM silicon nitride ceramics perform to the same mechanical needs as that of the conventionally manufactured variants. At present, these technologies are readily accessible for the fabrication of high-precision AM silicon nitride ceramic parts.

This information has been sourced, reviewed and adapted from materials provided by International Syalons.

For more information on this source, please visit International Syalons.