You may have heard that a hidden connection is stronger than an obvious one. In the realm of sealing technology, solutions tend to be found hidden inside complex systems. For the most part, seals are a critical component of any system, machine, or device – they are key in securing the function of many applications while preventing any leaks.

Almost everything we use or interact with on a daily basis requires a seal in order to function: dishwashers, dryers, cars, airplanes, portable healthcare devices, and satellites. Without proper seals, these systems would be rendered utterly useless or even experience a critical failure.

There are a multitude of seal types as well as a wide range of sealing environments. Omniseal Solutions designs and produces a range of polymer spring-energized and rotary lip seals that are made for challenging conditions and high-pressure sealing. In 2019, the company acquired American Seal & Engineering, which increased their portfolio with the addition of high-performance metal sealing solutions.

Now, having recently acquired HTMS (High Tech Metal Seals), Omniseal Solutions has now increased its presence and capacity for metal sealing in the nuclear and space industries by adding many decades of experience.

Founded in 1999 by a group of sealing specialists based in Mechelen, Belgium, Omniseal Solutions HTMS’ robust and flexible metal seals are considered to be invaluable where standard seals are unable to handle extreme pressure, temperature, or media.

Metal Seals: Why Are These Solutions So Solid?

Metal seals are rather diverse and utilized by many industries. They are best suited for:

- Industrial (valves, pumps and lasers)

- Semiconductors (tin shooters and catchers)

- Energy and power generation (steam and gas turbines)

- Oil and gas (high temperature and high-pressure valves, compressors and couplings in upstream)

- Science and research / fusion (vacuum vessels, reactors, connectors)

- Aerospace (valves, thrusters and cryogenic engines)

- Nuclear (reactors, pumps and valves, nuclear spent fuel casks)

- Automotive (exhaust, motor, turbo compressor)

Throughout Europe, there is a demand for metal seals in aerospace. As reported by Fior Markets, “The aerospace sector [is] anticipated to grow at the CAGR of 5.62% over the forecast period, mainly due to rising usage of metal seals in various aerospace applications such as engine system, airframe, flight control & hydraulic system, and landing gear system.” While this trend has probably altered due to today’s climate and circumstances, a drive for more efficient technologies continues and will eventually benefit this market in the long term.

Some sectors may emerge as requiring this type of metal sealing technology due to global demand, usage or other factors: including new research in nuclear science; commercialization of space, and developments in life science.

When manufacturing various parts of a satellite for the space industry, both metal and polymer seals are required. Moreover, as a picture of the future develops, an increase in fusion-based technology will be likely if countries pushing for clean energy deliver successful projects.

To ensure the supply of appropriate solutions for their customers, Omniseal Solutions HTMS offers a range of metal seal designs:

- Metal O-Seal

- Metal C-Seal

- Spring-energized metal O-seal

- Spring energized C-seal

- Spring-energized aluminum C-Seal

- Metal Commaseal®

- Metal Oysterseal®

Many of these seals can be customized to fit the customer’s application precisely. The range of Omniseal Solutions HTMS’ solutions is available in many shapes, sizes, and materials. The main differences between the different types of seal are the amount of spring back, seating stress, sealing surface, sealing load, and leak tightness.

Why are metal seals selected versus other solutions like PTFE seals? Metal seals are typically selected when PTFE seals have come to their ultimate limit concerning, pressure, temperature, chemical compatibility or required leakage rate in cryogenic conditions. PTFE seals tend to be restricted to the permeability of the PTFE in cryogenic conditions, while metal seals have no problem with permeability (besides from PTFE coating).

Custom Solution + Co-Development = Successful Application

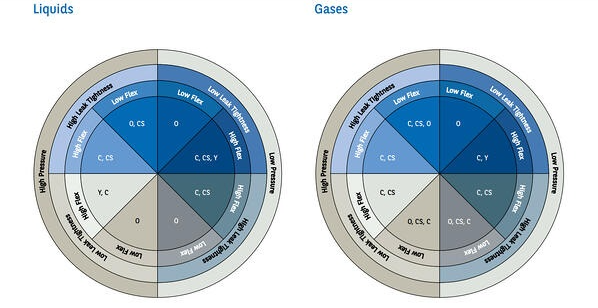

While ensuring the correct seal is selected is a crucial factor, the development of the solution is also critical. Therefore, Omniseal Solutions HTMS offers co-development with its customers – in fact, the company produces selection wheels (Fig. 1) so customers can review in advance and thus better understand how their applications could work before contacting HTMS. This proactive way of developing solutions ensures a mutual learning process and allows customers to understand why a specific seal is needed for the task.

In order to effectively design a metal sealing solution, consideration must also be given to surface finish as well as sealing load, flange deflection, and crucial variables in the development/design process of the seals. Omniseal Solutions HTMS takes time to assess and identify limiting factors in the application: these could range from bolt configuration (low compression force), to flange materials (soft materials require suitable seal designs), as well as the customer’s capability to achieve desired roughness properties and seal mounting (sometimes upside down), they must then design the seal appropriately.

Figure 1. Omniseal Solutions HTMS’ Customer Selection Wheels.

Image Credit: Omniseal Solutions

When working with a customer, Omniseal Solutions HTMS is fully committed to the customer’s needs from beginning to end product. The primary focus is to generate mutual trust and design a suitable solution with the customer. The values central to Omniseal Solutions HTMS are: to be responsive, agile, and flexible; to preserve short lead time; to pay attention to the customer’s needs; to design, engineer, and offer bespoke solutions; to be reliable; and to always deliver high-quality products.

Customer success stories are a consequence of integrating processes into their existing systems for improved control, developing alternate solutions where preceding ones have failed, and limiting downtime for those affected by inadequate solutions.

Known for their quick response time, Omniseal Solutions HTMS can deliver within two to three days when a solution is urgently required. For example, the company remanufactured a seal one day before their annual holiday period and directly delivered the seal themselves on Christmas Eve to the CERN facility in Switzerland. Another success was fabricating seals in just two days ready in time for a F1 race in Barcelona.

The Outside is Just as Important: Metal Seal Platings, Coatings, and Liners

While the inner design of the metal is key the outside is just as important. Metal seal platings, coatings, and liners have exceptional features in sealing technology. The additional soft layer is key in improving the leak rate. With three different types of soft layers in addition to a metal jacket, Omniseal Solutions HTMS has the ability to discover a complete solution for a significant majority of difficult and complex applications.

All three offer the same functionality to fill the roughness of the counter flange and enhance the sealing performance. The softer the plating, the more it can improve and cover surface irregularities in the hardware. Generally, a metal seal lies side by side with the high demands placed on the surface quality of the customer’s hardware.

For coatings, Omniseal Solutions HTMS typically applies PTFE, while plated seals use gold, silver, copper, tin, and nickel as a top layer. For jacketed seals, aluminum lining is used.

Looking Beyond: Future Metal Sealing Technology

The overall push to develop and utilize increasingly efficient applications translates to requirements moving in the direction where metal seals may be the only viable option. Requirements may differ through the combinations of higher and lower pressures, higher temperatures, better leakage performance, and wider range of use with one single sealing solution. Omniseal Solutions HTMS sees the developments and trends where standardization and robustness are concerned and where application parameters grow to be more challenging: temperatures increase, the need for double sealing barriers in vacuum, nuclear and fusion applications as well as the utilization of new materials (ceramics as flange material at very high temperatures).

As the world comes to terms with a pandemic, certain challenges may challenge the global metal seals market, such as worldwide political developments and embargos. Therefore, in order for Saint-Gobain HTMS to remain competitive and continually offer the highest standards to customers for the next twenty years or more, they are concentrating on providing quick turnarounds to all customer queries and requests for support; proper and accurate technical advice; and promise to provide high-performance seals that are fit for purpose – “offering the best solution for the application.”

With the latest merger between HTMS and Omniseal Solutions, the optimal sealing solution can now be a simple choice between metal or polymer.

This information has been sourced, reviewed and adapted from materials provided by Omniseal Solutions.

For more information on this source, please visit Omniseal Solutions.