Please can you introduce yourself and your role at Olympus?

Hello, everyone! My name is Vladimir Vermus, and I have been working for Olympus’ X-ray fluorescence (XRF) and X-ray diffraction (XRD) analytical instruments division for 10 years. I had a background in mining engineering when I started out in sales at Olympus Moscow, and my current role is XRF/XRD Business Specialist for Europe, the Middle East, and Africa (EMEA).

I am convinced that in a few years the control of the chemical composition of products will penetrate the most unexpected sectors of the market, and I think XRF and XRD technology has a major role to play.

How can catalytic converters be recycled?

It is worth beginning with a short explanation of the function of a car catalytic converter (also car catalyst or car cat). The purpose of these converters is to reduce the emission of pollutants in a car’s exhaust gases into the atmosphere.

A car catalytic converter is a honeycomb cylinder with a layer of platinum (Pt), palladium (Pd), and rhodium (Rh) - also known as platinum group metals, or PGMs - deposited in various combinations on its surface. Unburned residues from carbon monoxide (CO), hydrocarbon (CH), or nitrogen oxides (NO) that touch the surface of the catalytic layer are oxidized by the oxygen present in the exhaust gases and are neutralized.

Over the past 50 years, the car catalyst has become an integral part of internal combustion engine vehicles. The average life of the car catalyst depends on several factors, such as the quality of the fuel and engine volume, but it typically lasts for up to 100,000 km (or around 62,000 miles). With proper disposal of the car catalyst, we can provide a second life for the PGMs in them. From sorted and properly prepared used catalysts, PGMs can be recovered and reused in the production of future car cats.

Currently, these reprocessed PGMs account for around 40% of the total catalyst production, and even this amount cannot satisfy the growing market demand. At present, the recycling of car cats is not just an economically profitable enterprise, but also a necessity projected by the trends in the development of the world economy and environmental standards.

Pieces of catalytic converter containing precious metals for recycling. Image Credit: Shutterstock.com/Adam J

Why is it economically and environmentally beneficial to recycle catalytic converters?

Platinum and palladium are two elements that most effectively handle the neutralization of harmful emissions. Although platinum is used in a number of industries other than automobile manufacturing - jewelry production, for example - 90% of the palladium produced today goes toward the production of car cats. With the adoption of new fuel standards (China VI, Tier 3, Euro 6d, Bharat 6), it is safe to say that in the coming years, the demand for palladium will grow. So, in terms of assessing demand, car cat recycling is attracting significant interest.

Of course, an important fact is that recycling used car cats is much less harmful from an environmental point of view than extracting PGMs through mining; the carbon footprint alone is incomparable. Not to mention the fact that palladium is for the most part a by-product for miners and the level of its extraction efficiency is low.

How do Vanta™ XRF analyzers enable the recycling of catalytic converters?

The X-ray fluorescence (XRF) testing method, which was introduced into car cat processing from the mining and scrap processing industry, has proven indispensable for this application. It provides users with concentrations of Pt, Pd, and Rh in a spent catalyst in seconds. It is impossible to determine the content of PGMs in car cats without using special devices. This is where portable XRF (pXRF) assists the processor.

With portable XRF, you can sort catalysts into groups for optimal extraction of PGMs and set the purchase price correctly. Portable XRF is a must-have tool for the car cat recycling business, along with a grinder, mixer, or scales.

What element suite do the Vanta analyzers account for?

The Vanta XRF analyzer series offers the classic range of elements for handheld XRF instruments - from magnesium to uranium, simultaneously displaying up to 45 elements contained in a sample.

Of course, regarding the car cat application, the group of elements of interest is much narrower: Pt, Pd, Rh, tantalum (Ta), cerium (Ce), selenium (Se), tungsten (W), silicon (Si), zirconium (Zr), palladium (Pb), ruthenium (Ru), lanthanum (La), nickel (Ni), and sulfur (S).

In the end, these elements will determine the cost of raw materials. All these elements are prioritized and included in the specialized Vanta Car Catalyst mode or method. However, you still can analyze other elements from Mg to U range.

How does Olympus protect against fraud in catalytic converters?

With the continued growth of the car cat recycling business, so grows the number of fraudsters trying to sell spent car catalysts at as high a price as possible. The most common way to boost the car cat’s value is to increase the mass of raw materials with lead-containing additives. There are also more sophisticated methods of deception, such as adding tantalum or selenium to the mixture to simulate the platinum peaks on the XRF spectrum.

An error can also occur without malicious intent - for example, a pXRF with a nonspecialized calibration can easily mistake tungsten in a diesel particulate filter (DPF) for platinum - such cases are quite common. Either way, Vanta XRF can help avoid this confusion, the unique calibration of the Vanta analyzer helps prevent such mistakes.

How should samples from the catalytic converter be prepared to obtain accurate and representative results?

Fig. 1 - Example of a car cat lump sample and preliminary Pd concentration (ppm) results to aid in rough sorting. Image Credit: Olympus

|

Sample preparation is an essential part of XRF analysis. 90% of all XRF errors are associated with sample preparation. In the field of car cat recycling, two types of samples are usually handled: lump samples (whole or split body) and powder samples. PGMs on the surface of the honeycomb structure are distributed somewhat unevenly (Fig. 1), so lump sample tests can only provide a preliminary assessment, enabling you to separate the car cats by type and reject any “empty car cats” from which the PGMs have already been removed, particularly when buying small batches of raw materials.

To sort raw materials for subsequent enrichment or large batches, additional steps for sample preparation are required for representative results. In general, we recommend the following 1) rough sorting by type and rejection of any pacifiers, 2) each group is crushed separately - it is important that the particle size distribution is as homogeneous as possible - 3) homogenization, and 4) sampling - if desired, you can use a press. This enables you to get a good library of standard samples over time.

We also recommend monitoring the humidity very closely. Fluctuations in humidity of more than 10% can greatly affect the accuracy of the analysis. After the sample has been obtained, 3–5 tests should be done with subsequent averaging. If no mistakes were made at the stage of sample preparation, there should be an absolute average error around 4 ppm–31 ppm.

How do the different Vanta models compare?

Olympus offers several Vanta models for the car cat application. The main difference between them is the speed of analysis, sensitivity, and the ability to determine light elements, that is, magnesium (Mg), aluminum (Al), silicon (Si), phosphorus (P), and sulfur (S).

The Vanta L model is an economical device for sorting raw materials by type. The device is equipped with a PIN detector, so it cannot detect elements lighter than titanium. The average analysis time on the Vanta L analyzer is around 40–60 sec.

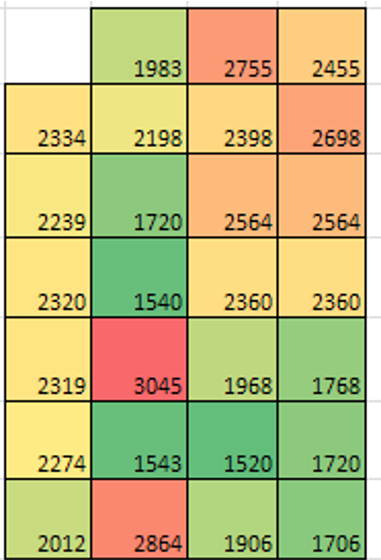

The Vanta C and M series are devices with a silicon drift detector (SDD) technology capable of detecting light elements. These models will help to determine the silicon carbide (SiC) content as well as control the sulfur content. An average testing time on these devices will be around 15–20 seconds, enabling you to do 3 times more analysis per shift than on devices with a PIN detector. The difference is shown in results and errors in table 1 for Pd, in ppm. The Vanta M analyzer’s measurement results with a 5-second test are near equal to the 60-second measurement with the Vanta L analyzer.

Table 1. A comparison of the Vanta L and Vanta M model results and errors for Pd in ppm.

What features does the Vanta range have that make it suited for this application?

The first thing you will notice when using a Vanta analyzer is the stability of the calibration and the repeatability of the results. It is hard to believe that these results come from a portable XRF. Moreover, thanks to the Axon Technology™ electronics, you can be confident that the readings of one Vanta analyzer will not differ from the results of the next Vanta analyzer, or the next, and so on. This is especially beneficial for large players in this market. Additionally, it offers the possibility to adjust the device for differing matrices using the “User Factors” function. So, now it is as simple as changing the clock when you travel to another time zone.

Both the tungsten and silver anode X-ray tubes are ideal for car catalyst analysis. With a rhodium anode, there would be corresponding characteristic peaks on the spectrum.

It is important to point out the size of the measuring window in the Vanta analyzer. A large window enables us to analyze a large surface area, increasing the statistical selection.

Recycling catalysts is an extremely dusty process, so the IP55 dust and moisture protection index is obviously beneficial. In general, the 3-year warranty for the Vanta series’ main line is a significant ownership advantage.

Fig. 2 - Vanta Work Station. Image Credit: Olympus

For work within the process production, we offer our customers the Work Station (Fig. 2) which turns Vanta into a full-fledged benchtop XRF for easy stationary use.

In line with Industry 4.0, are the network connection and reporting benefits. With the Vanta analyzer, you can send data from devices directly to the ERP system, without user intervention. This capability helps make your business as transparent and controllable as possible.

How do you hope to improve catalytic converter analysis in the future? What is the next step for Olympus?

With the rapid growth of the car cat recycling market, refineries will tighten requirements for incoming raw materials. In the calculation of the cost of raw materials, the content of silicon carbide and sulfur will be increasingly contributing factors. Consequently, devices with a silicon drift detector (SDD), as well as X-ray powder diffractometers (XRD), will become increasingly popular. Olympus’ TERRA™ II X-ray diffraction analyzer, for example, can not only provide a quantitative estimate of the SiC content but also determine a specific phase of it.

As new types of catalysts are constantly being developed, the task for Olympus is to constantly monitor manufacturers’ needs and update the calibration to incorporate new samples, which is exactly what our customers want from us.

In the future, as we develop our cloud system, the Olympus Scientific Cloud™, we will be able to offer car cat recyclers not only a measuring tool but a whole cloud-based ecosystem of accounting and statistics, which for many smaller players could be a key to success.

Where can readers find more information?

https://www.olympus-ims.com/en/downloads/detail/?0[downloads][id]=276828424

About Vladimir Vermus

Vladimir Vermus is Olympus’ EMEA ANI Business specialist and a five-time SSD Olympus Excellence Award winner.

This information has been sourced, reviewed and adapted from materials provided by Evident Corporation.

For more information on this source, please visit Evident Industrial (XRF).

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.