The modern beverage and food industry is not imaginable without food-grade carbon (CO2) dioxide. Some of the uses of food-grade CO2 include carbonation of beverages, and it is also used as packaging and cooling gas.

This article investigates volatile organic impurities developing from a food-grade certified (European standard E 290) carbon dioxide cylinder using a PTR-TOF 1000 ultra.

Download the full poster here

Download the full poster here

The PTR-TOF 1000 ultra is a compact PTR-TOFMS available with the ION-BOOSTER funnel technology. The high sensitivity of the PTR-TOF 1000 ultra allows it to be considered as an ideal tool for applications where complex matrices have to be rapidly examined. Quality assurance in the food and flavor industry is one such example application.

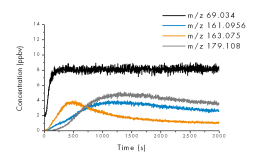

Concentration vs. time. Impurities show different dynamic. Image Credit: IONICON Analytik

Concentrations of volatile impurities detected in food-grade CO2 show a dynamic behavior, with maxima at varied times after opening the cylinder. Consequently, the introduction of the CO2 into food or the time of measurement for QA will have a major influence on the level of impurities.

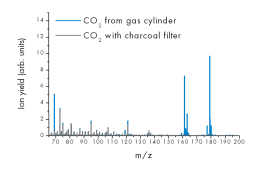

Comparing mass spectra of filtered and unfiltered CO2. Impurities are visible. IONICON Analytik

The great advantage of real-time analysis in food and flavor quality assurance is highlighted by these results that also demonstrate the benefits of using the PTR-TOF 1000 ultra instrument.

Click here to download the poster

Click here to download the poster

This information has been sourced, reviewed and adapted from materials provided by IONICON Analytik.

For more information on this source, please visit IONICON Analytik.