It is usually cases, such as melamine in milk, where food adulteration makes the news.1 Yet, high-value products are frequently subjected to adulteration by lower-value materials, and this can be challenging to detect.

Extra virgin olive oil (EVOO) is a high-priced product. A pint of it is close in cost to half a gallon of food-grade olive pomace oil.

When using a variety of procedures (gas chromatography [GC], ultraviolet and visible spectroscopy [UV/Vis], liquid chromatography [LC]), and wet methods, the University of California at Davis has reported that the majority of the extra virgin olive oils sold in California fail the tests for the same (EVOO).2

Yet, one would expect a relationship to its thermal properties considering the way EVOO is made. Differential scanning calorimetry (DSC) is frequently utilized to analyze foods in both research labs and quality control.3, 4

DSC is frequently employed to compare materials on heating, but as materials can respond more thermodynamically under controlled cooling, cooling studies often give more information.5

Experimental

Materials

Initial samples of four commercial olive oils were gathered locally, and then samples of high-grade EVOO were collected directly from small producers. Samples of freshly pressed mono and multi varietal EVOO, together with refined and salvage oil with known processing histories, were also obtained.

When not used, all samples were stored in a cool, dark room under N2 purge.

Instrumental

4-8 mg samples of the different oils were pipetted into pre-weighted and matched aluminum DSC sample pans (PerkinElmer Part No. 02190041). These were then run on a PerkinElmer DSC 8500 under N2 purge at 20 cc/min and cooled from room temperature at a rate of 5 °C per minute down to -60 °C.

A two-stage refrigerated cooler was utilized for this study. After reaching -60 °C, to ensure complete cooling, the samples were held for three minutes. Next, the samples were heated at 10 °C per minute until they were back to room temperature.

All samples were run in triplicate, and the results averaged.

Figure 1. The DSC 8500 is a dual furnace power compensated design differential scanning calorimeter capable of very precise control on heating and cooling. Image Credit: PerkinElmer Food Safety and Quality

Results

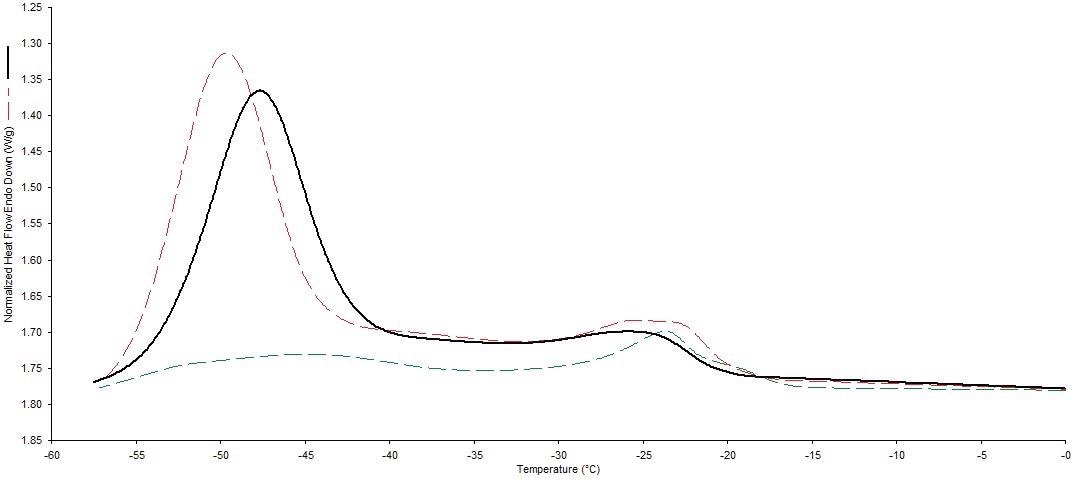

Distinct thermal differences were seen in the commercial samples of olive oil. Extra virgin (solid), refined (dashed) and pomace (dotted) olive oils are shown during the cooling run.

Figure 2. Grocery store grades of extra virgin, refined and pomace olive oils were run by controlled cooling in the DSC. Notice the distinctive fingerprints, particularly of the pomace oil, which lacks the low temperature peak. Image Credit: PerkinElmer Food Safety and Quality

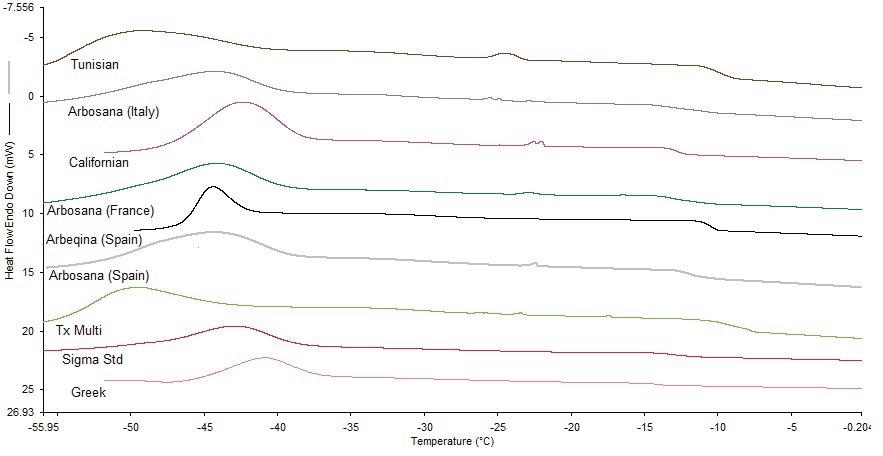

As seen in Figure 3, a series of EVOO samples were run that were most likely to be extra virgin, in addition to two received directly from a Texas-based producer who could assure this. Although it is preliminary, the data exhibits some interesting features.

Firstly, the higher-temperature peak appears in the same temperature range as the pomace oil peak, but even compared to the grocery store EVOO, it is very small. This data indicates that the grocery store EVOO could be diluted with another oil.

Secondly, with the varietal and origin of the oil, it appears that there are shifts in the temperatures and peak shapes. For instance, note the difference in peak position and shape and of the low temperature peak between the Spanish Arbeguina and the Spanish Arbosana.

As seen in Texas versus Spanish Arbeguina scans, the origin appears to be complicated. Further work would be required to see if this holds, but it seems likely based on previous work with nut oils6.

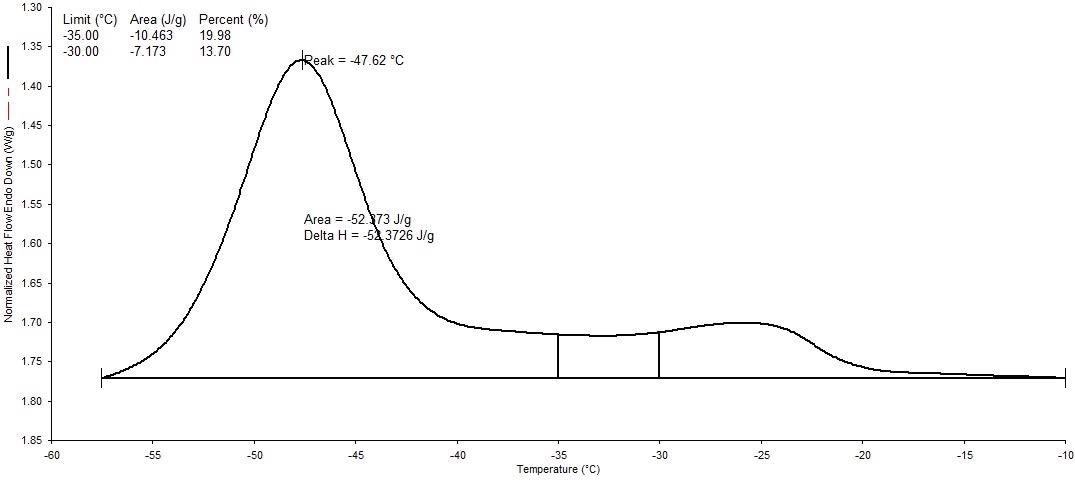

As shown in Figure 4, characterizing these differences is often done by taking partial areas under the curve. This can be seen for EVOO and a large high-temperature peak similar to that of the pomace oil was observed in all the grocery store samples in contrast to the truly EVOO samples seen in Figure 3.

Figure 3. High-quality EVOO from small batch suppliers. The Texas EVOOs were of known origin. Note the lack of strong "pomace peak". Image Credit: PerkinElmer Food Safety and Quality

Figure 4. Multiple peak areas in a DSC scan analyzed by the partial areas technique. Only three partial areas are shown above for clarity. Image Credit: PerkinElmer Food Safety and Quality

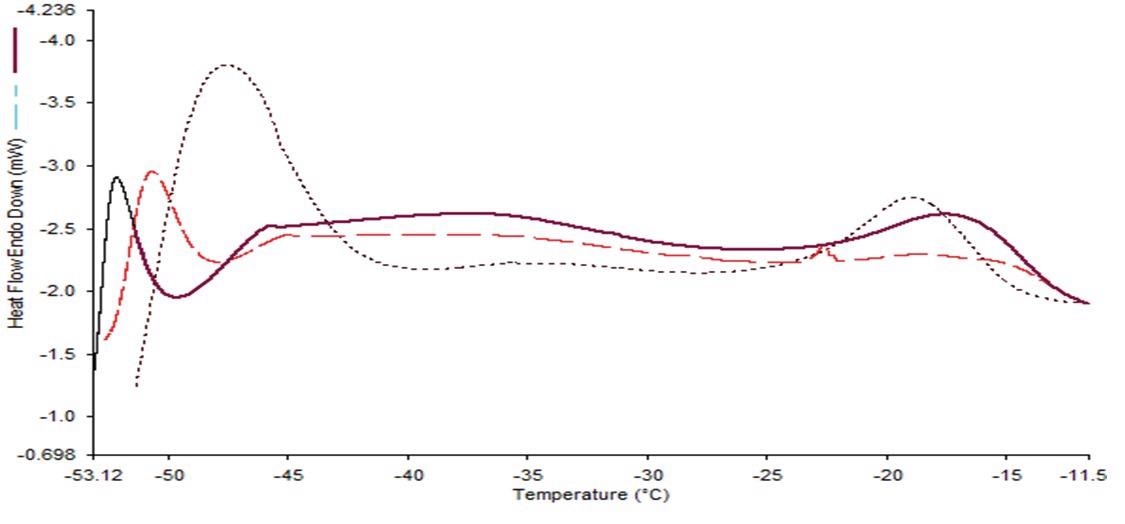

It is likely that materials could be sorted based on this method with the "pomace peak" happening in the -20 °C to -10 °C range and the major "EVOO peak". To confirm this, blends of EVOO and pomace oil in three amounts were created. Figure 5 shows the thermograms overlayed.

This data was employed to create a simple model from the partial area data shown. Linear regression suggests the addition of more than 7 % olive oil-based adulterant to the olive oil can be estimated.

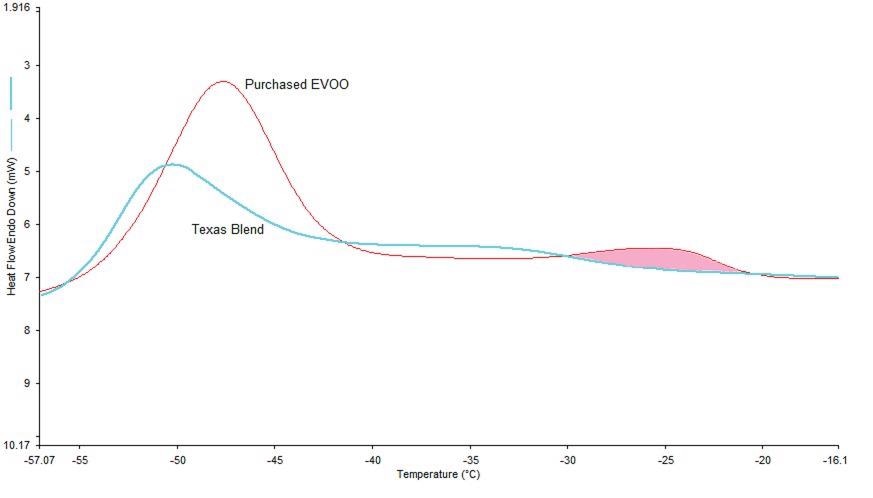

We suspect the grocery store EVOO to have 12-15 % adulterant or to be pressed at higher temperatures (see Figure 6) based on this method. More exacting model methods are expected to give better results, such as those employed in TIBCO Spotfire® software.

Figure 5. 25% EV (dashed), 50% EV (solid), and 75% EV (dotted) oils during the cooling run. Image Credit: PerkinElmer Food Safety and Quality

Figure 6. Overlay of the purchased EVOO and the Texas blend of known EVOO. The area of increased "pomace oil" is highlighted. Image Credit: PerkinElmer Food Safety and Quality

Conclusion

Controlled cooling in the DSC represents a way to extract information not normally accessible from food products using other techniques. Extra virgin olive oils have a distinct cooling profile that is different from lesser grades, and this profile is quite responsive to alterations in composition.

In addition to possibly identifying the varietal utilized to produce the oil, this supplies a technique for addressing adulterants. Further work is planned on the influence of temperature and UV radiation.

References

- H. Hong. “China seizes 26 tons of melamine-tainted milk” CNN. https://edition.cnn.com/

- E. Frankel, R. Mailer, S. Wang, C. Shoemaker, J-X. Guinard, J. Flynn, and N. Sturzenberger, Evaluation of Extra-Virgin Olive Oil Sold in California, University of California at Davis: Davis, CA, 2011.

- V.R. Harwalkar and C. Ma. Thermal Analysis of Foods. Elsevier: Amstedam, 1990.

- D. Burlett, "Quality Control" in Handbook of Thermal Analysis V5, M Brown and P. Gallagher. Editors, Elsevier: Amsterdam, 715, 2008.

- J. Menczel. Thermal Analysis of Polymers. Wiley: Hoboken. 2009.

- S. Dyszel and B. Pettit, "Determination of the country of origin of pistachio nuts by DSC and HPLC" Journal of the American Oil Chemists’ Society, 67, 947, 1990.

This information has been sourced, reviewed and adapted from materials provided by PerkinElmer Food Safety and Quality.

For more information on this source, please visit PerkinElmer Food Safety and Quality.