Reviewed by Lexie CornerJul 9 2025

A study published in Advanced Materials reports that Chengcheng Fang, an assistant professor in the College of Engineering, and Mojgan Nejad, an associate professor in the College of Agriculture and Natural Resources, collaborated to develop a thin film battery separator using lignin.

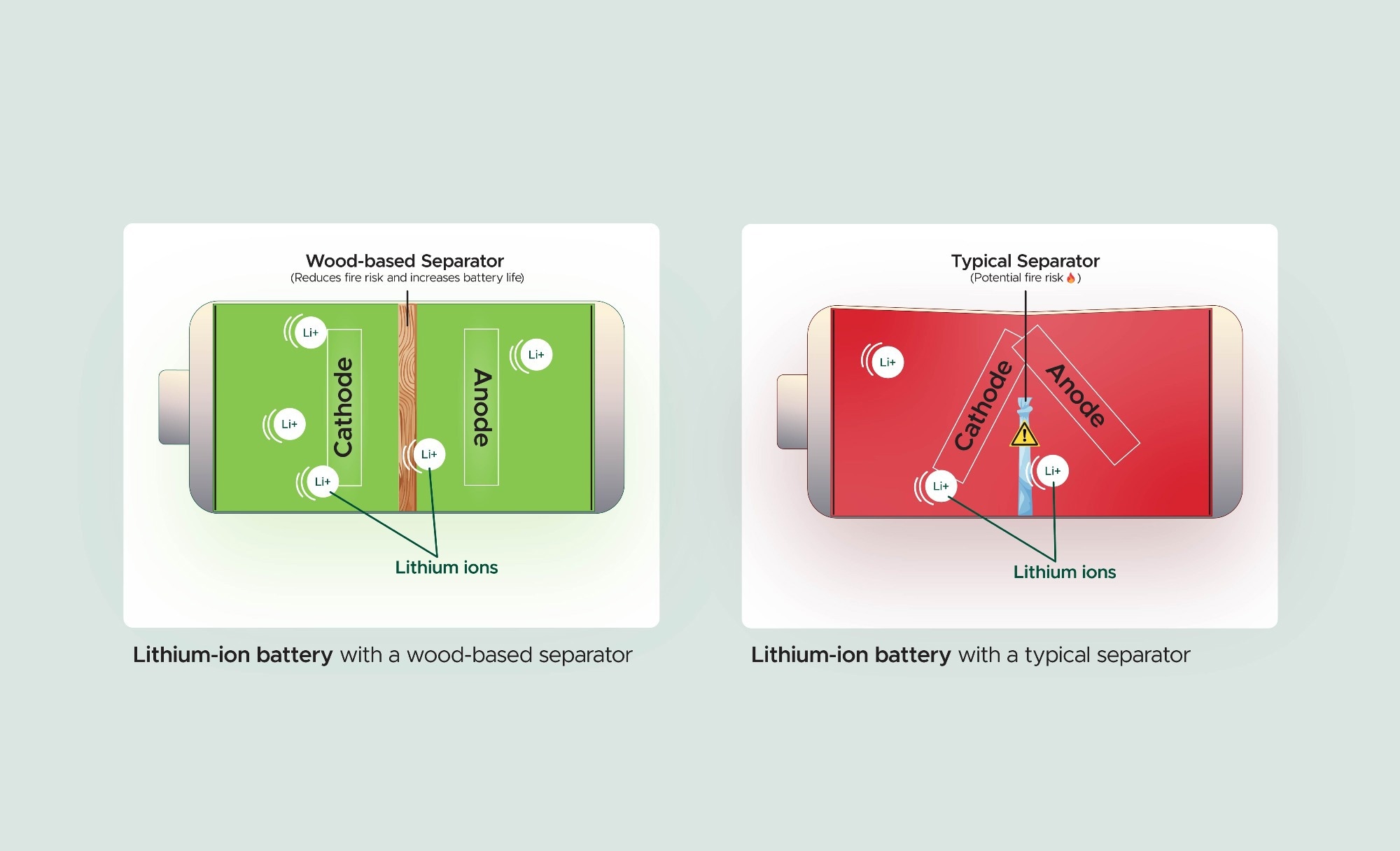

Lignin is a natural component of wood that provides structural support. The separator can be applied inside lithium-ion batteries to help prevent short circuits that may lead to fires.

L-R: Wood-based separator in a lithium-ion battery versus a typical plastic separator in a lithium-ion battery. Image Credit: Michigan State University/Molly Killingbeck.

L-R: Wood-based separator in a lithium-ion battery versus a typical plastic separator in a lithium-ion battery. Image Credit: Michigan State University/Molly Killingbeck.

Researchers at Michigan State University found that natural materials from wood can improve battery safety and extend battery life. This is relevant for consumer products such as phones, laptops, and electric vehicles, which all rely on lithium-ion batteries.

We wanted to build a better battery. But we also wanted it to be safe, efficient, and sustainable.

Chengcheng Fang, Colleges of Engineering and Agriculture, Michigan State University

In a lithium-ion battery, the anode (negatively charged) and the cathode (positively charged) enable the flow of electricity. Commercial separators are typically made from plastics like polyethylene or polypropylene. These materials can shrink at temperatures near 100 °C. If the separator fails, the electrodes may touch, which can lead to a short circuit and potentially cause a fire or explosion.

In contrast, the lignin-based separators remained stable and did not shrink at temperatures up to 300 °C.

Fang’s team tested different thicknesses of the lignin film. They found that a 25-micrometer film - thinner than one-fifth the width of a human hair - was most effective in maintaining battery stability and preventing contact between the electrodes.

The lignin film also improved battery cycle life. This means the battery could be charged and discharged more times due to the material’s thermal and structural stability.

“We were surprised to see that the lignin film also improved the battery’s cycle life. We increased the battery’s cycle life by 60 %,” added Fang.

There were environmental advantages as well. The team used a dry processing method to manufacture the lignin separators. This method avoided the use of toxic solvents that are common in producing conventional separators.

The process allowed for large-scale production of the film without generating waste or pollution. The team achieved full material conversion using lignin and other inputs, resulting in zero manufacturing byproducts.

“Lignin, particularly lignosulfonate, is naturally abundant, and it doesn’t need any further treatment to function in batteries. This work demonstrates a new design pathway to improve both the safety and manufacturability of battery materials,” concluded Fang.

The MSU Innovation Center is pursuing a patent for the invention.

Journal Reference:

Jia, H., et al. (2025) Lignin-Based Separators for Lithium-Ion Batteries via a Dry Fibrillation Method. Advanced Materials. doi.org/10.1002/adma.202419694.