Image Credit: Stable Micro Systems Ltd

What is Mechanical Testing?

Mechanical testing is a way of testing and measuring the properties of materials. Machines/instruments are available to test materials or finished products in a range of different ways including compression, flexure or tension in order to measure forces resulting from these actions that may result in a material breaking, snapping, bending or yielding during the test.

Why is Mechanical Testing important?

Performing mechanical testing is important to characterise the properties of a material or provide validation for final products to ensure that they are fit for purpose and safe to use or employ. You will want to choose the components with the right properties in your design process in order to create a product with intended functionality. Once created, you will need to ensure that throughout your repeated manufacturing you can continue to produce a product with the desired properties and ensure consistency in output and safety in use.

Fundamental mechanical testing aims to determine a single material’s mechanical properties independent of its geometry. Raw material batches are liable to variability, so mechanical testing of each batch ensures that it meets minimum strength requirements.

Empirical or imitative testing also exists to provide a means of measuring either a composite material of certain dimensions or being able to determine the response of a structure or finished product to a given action, e.g. how a concrete bridge might bend during a load, how food packaging might compress/deform when stacked to a certain height.

Image Credit: Stable Micro Systems Ltd

How Mechanical Testing equipment works

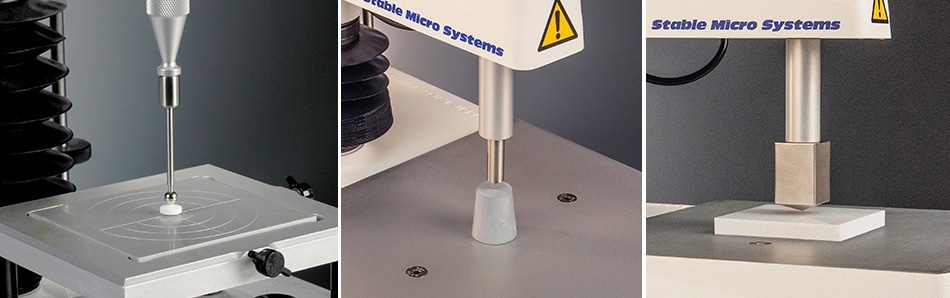

Typical compression, tensile and bending tests. Image Credit: Stable Micro Systems Ltd

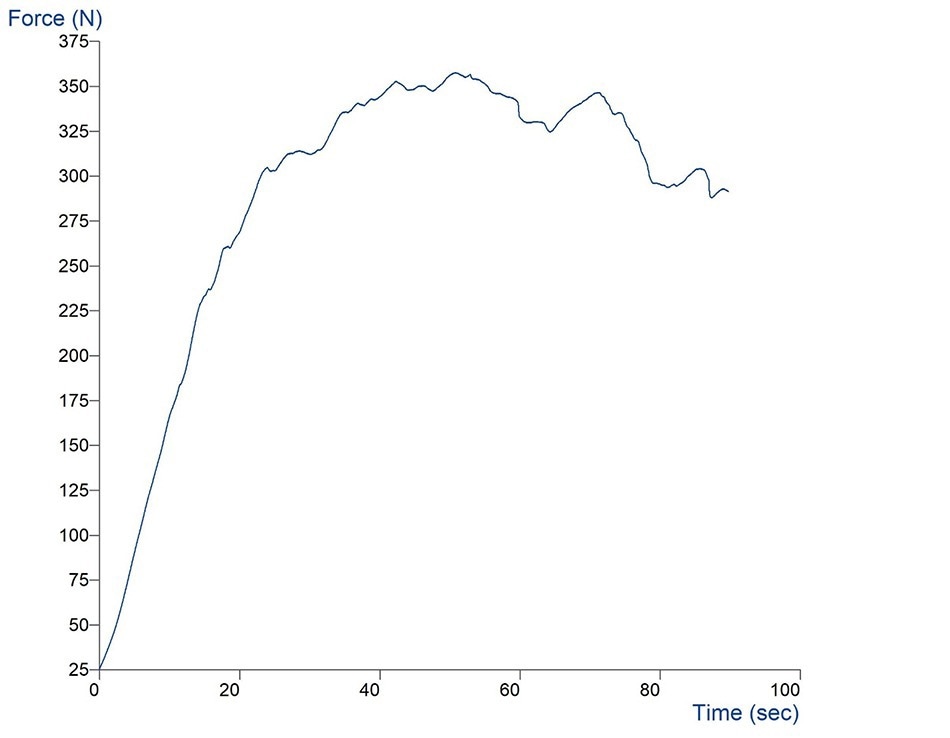

A Texture Analyser/Materials Testing instrument is a mechanical measurement system that moves in either an up or down direction to compress or stretch a sample, usually to its point of failure. The travelling arm is fitted with a load cell and records the force response of the sample to the deformation that is imposed on it. Force, Distance and Time data (or stress-strain) is collected and usually presented as a curve on a graph which, when analysed, indicates the mechanical properties of the sample.

Example graph - Box compression. Image Credit: Stable Micro Systems Ltd

Examples of Compression testing

Examples of Tensile testing

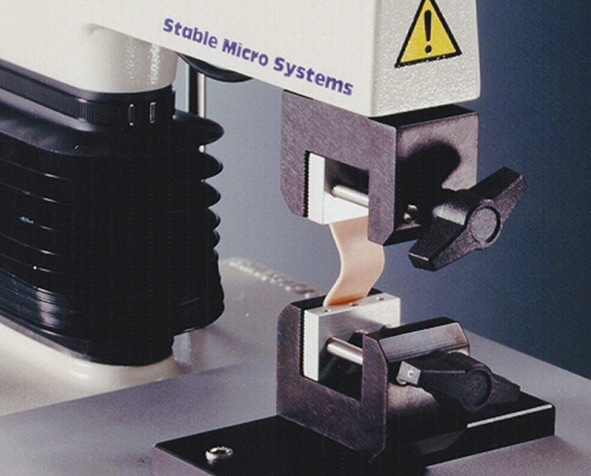

How to do Tensile Testing using a Texture Analyser

How Mechanical Testing equipment can be applied/used

When designing a product or choosing materials to create a product, the materials must have the ability to withstand the purpose for which they are to be used. For example, a consumer must be able to apply a degree of flexure to utensils when cutting food without the knives/forks/spoons bending whereas an aircraft wing should allow a degree of flex/bending during flight as a rigid wing is more susceptible to metal fatigue and therefore has a shorter lifespan. It is also much easier and lighter to have wings flexing as they act as shock absorbers in case of air potholes.

Whilst many materials can be measured manually to obtain a ‘gut’ feeling about its properties, subjective testing lacks accuracy and precision. The use of a quantitative, calibratable, verifiable instrument that provides accurate, repeatable, archivable and traceable results provides the best level of certainty when assessing material properties, especially true when safety is involved and where archived data can be retrieved to compare batches of material or digital evidence of testing.

Image Credit: Stable Micro Systems Ltd

Having a means of measuring mechanical properties also allows you to benchmark your product’s physical characteristics against that of other products e.g. competitors, and if required, provide a means of quantitatively substantiating any product mechanical characteristics such as 50% stronger.

What properties can Mechanical Testing equipment measure?

A material’s ability to bend, compress or stretch can be an advantage or a disadvantage depending on the purpose for which it is to be used. The means to measure how a material behaves under varying degrees of flexure, compression or tension allows the designer to choose the desired properties based on the application.

Hardness testing is the most common mechanical assessment for materials test equipment that provides compression or penetration resistance measurement including such tests as Brinell, Shore, Vickers whilst in tension the most common tensile properties are tensile strength/stress/strain, Young’s modulus, yield stress and % elongation.

Brinell, Shore and Vickers Hardness tests on a Texture Analyser/Materials Testing Instrument. Image Credit: Stable Micro Systems Ltd

Other important mechanical qualities include fracture toughness, stress rupture, creep testing, and fatigue testing, which enable designers and engineers to predict the lifespan of a component or final product. Testing for fracture toughness can reveal information about a material's resistance to faults and how they affect its strength because components will eventually develop cracks over the course of their lifetime. The purpose of fatigue testing is to establish operating conditions under which fatigue would not occur during the lifetime of the component or finished product, or to assess the material's capacity to withstand cyclic loading under varying stress levels, in order to ensure that it can meet its intended life expectancy of continued use. Designers and engineers can make better decisions by choosing materials or components with enhanced fracture toughness or fatigue resilience to improve designs and prolong life expectancy.

Cycle loading of a sample. Image Credit: Stable Micro Systems Ltd

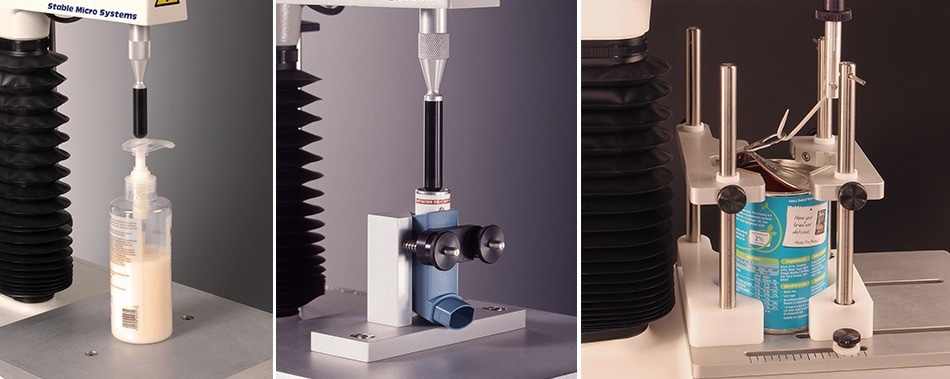

Whilst there are a well-established range of fundamental measurements that are routed in engineering, there exists a set of more simple measurements that attempt to mimic how a finished product would be used by a consumer and hence measure the experience that the consumer would encounter whilst using that product. Typical examples include the force required to actuate a soap dispenser, metered-dose inhaler or remove a ring-pull lid.

Mechanical testing of a soap dispenser, metered-dose inhaler and ring pull. Image Credit: Stable Micro Systems Ltd

Mechanical testing properties that are also available (via other instrumentation) include corrosion resistance to know how rust, chemical damage, or other wear and tear-resistant something is and impact resistance testing which is concerned about how much force (generally provided by a pendulum) a part can take before it would break.

This information has been sourced, reviewed and adapted from materials provided by Stable Micro Systems Ltd.

For more information on this source, please visit Stable Micro Systems Ltd.