In this interview, AZoM talks to Christine Desplat about the versatility and convenience of One-Part Epoxy Systems.

What are one-part epoxies, and where are they used?

One-part epoxy adhesives are excellent options for bonding, sealing, coating, and potting/encapsulation. They are used in some of the most sophisticated applications in the aerospace, electronics, optical, medical, oil and gas, and OEM industries. Since mixing is not required, the processing is simplified.

In a one-part epoxy, the resin and curing agent are both present within the system. A reaction occurs once heat is added, as the curing agent is not active due to the presence of inhibitors. Adding heat eliminates these inhibitors, thereby causing the reaction to occur. Up until then, the stability and shelf life of these systems are quite good, and one-part systems can be applied at any time prior to the addition of heat.

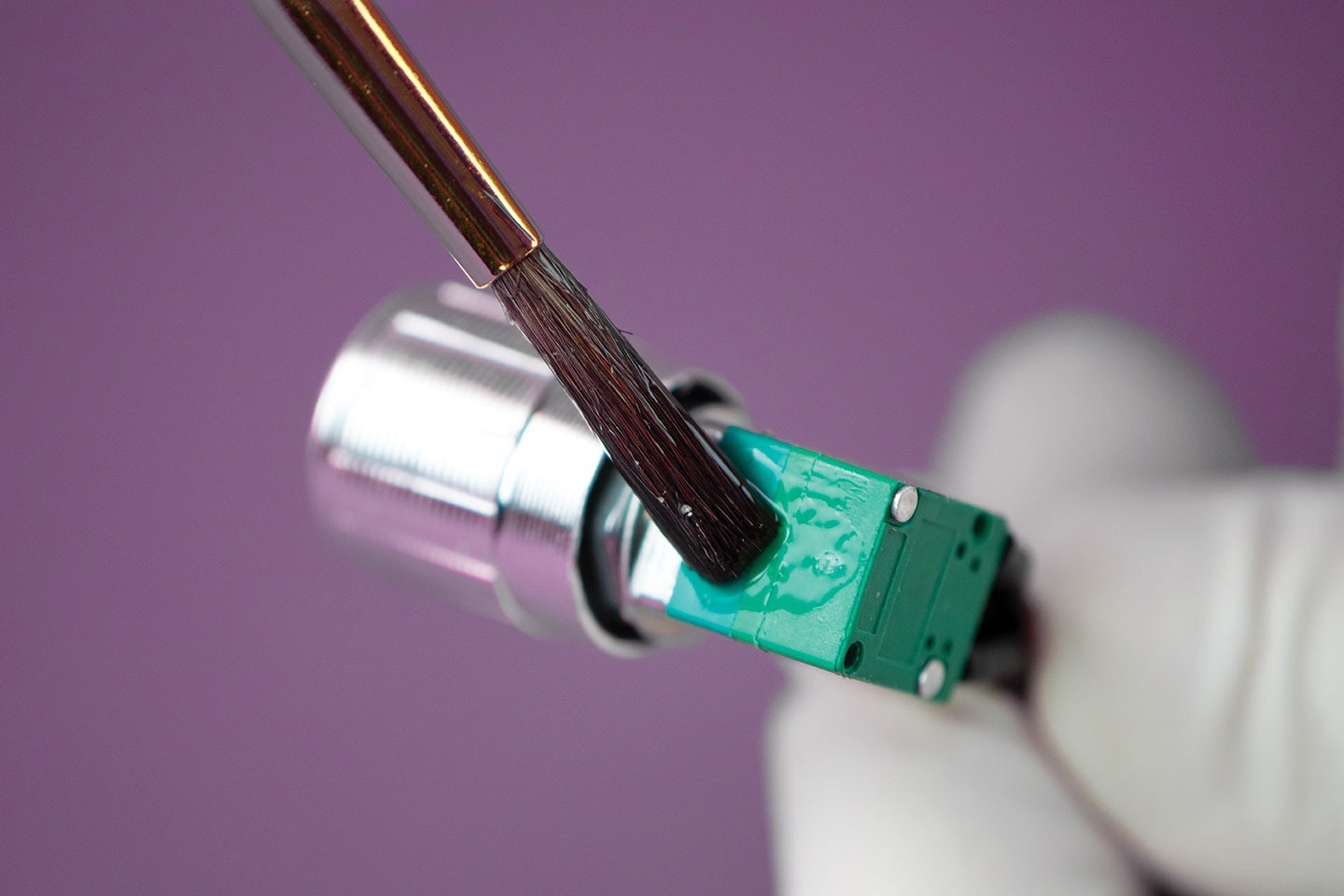

EP3RR-1 is a one component epoxy for potting, encapsulation and underfill applications with good flow properties. Image Credit: Master Bond Inc.

What temperature is required for curing a one-part system?

Most one-part systems require a temperature of 125 °C to 150 °C for curing, although specialty grades now exist for an 80 °C cure. These can be particularly beneficial for bonding heat-sensitive substrates.

How long does it take to cure a one-part epoxy?

The curing times of a one-part epoxy can range from a couple of minutes (e.g., a snap cure) to many hours. Adding heat to initiate a cure will never result in a full cure; the heating cycle must be thorough and complete. Typically, forced air convection ovens are used to cure these one-part epoxies.

What are the key advantages of a one-part epoxy?

One-part systems eliminate the need for measuring and mixing and, in a sense, have unlimited working life. That is to say, for most one-part epoxies, the open time is comparable to the shelf life, in that the system will not fully cure until the appropriate amount of heat is added. This is what separates the true one-part epoxies from pre-mixed and frozen systems, which typically need storage at –40 °C.

On the other hand, true one-part epoxies can be stored at room temperature or in a standard refrigerator.

What kind of performance properties can a user expect from a one-part system?

Fully cured one-part epoxies offer many desirable properties, including excellent bond strength to a wide variety of substrates, outstanding mechanical and physical strength properties, robust temperature resistance and the ability to withstand chemicals.

Properties such as viscosity, chemical resistance, temperature resistance, optical clarity, electrical insulation/conductivity, thermal conductivity, and cure speed can be modified to meet specific application requirements.

For example, formulations are available to withstand cryogenic conditions, meet NASA low outgassing specifications, or pass USP Class VI biocompatibility standards. One significant application issue regarding one-part epoxies is that they are more exothermic than two-part systems and, in most situations, are limited by curing depths 1/4 inch or less.

Can you provide examples of how one-part systems might be used in a specific application and what factors to consider?

One instance would be an underfill system, where the epoxy is designed to protect and support delicate flip chips. Important considerations would be good flow along with superior dimensional stability upon curing. Ultra-low viscosity one-part epoxies are well suited for various vacuum impregnation applications, ranging from transformer coils to carbon fiber composites.

Another example where one-part epoxies can be used is as glob tops encapsulants where a thixotropic product is needed. Glob tops can be applied to circuitry, wire bonds, and even delicate electronic components. They can also function as die attach compounds.

In general, one-part epoxies can be applied to protect electronic assemblies from a host of conditions, from environmental to more extreme thermal and mechanical stresses. In electro-optical devices, one-part epoxies are well suited for bonding LED and display assemblies, as well as fiber optics bonding, sealing, and coating.

There are countless other examples that include cryogenic conditions, medical device assembly, and OEM manufacturing. These are just a few examples.

To sum it up, one-part epoxy compounds offer a range of properties and perform well in a wide variety of applications. These versatile systems can be formulated to achieve dozens of combinations of physical, thermal, and electrical properties. If heat curing is possible and practical, one-part epoxies are an excellent option because of their outstanding performance profile and relatively easy and convenient processing.

EP4CL-80Med is a one part, biocompatible epoxy that offers optical clarity and was developed for use in medical device assembly applications. Image Credit: Master Bond Inc

About Christine Desplat

Christine Desplat is an Application Engineer at Master Bond Inc. She analyzes application oriented issues and provides product solutions for companies in the aerospace, electronics, medical, optical, and oil/chemical industries.

This information has been sourced, reviewed and adapted from materials provided by Master Bond Inc.

For more information on this source, please visit Master Bond Inc.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.