What is surface analysis, and why is it important in manufacturing?

Surface analysis is the measurement of the chemical composition of the surface of a material, i.e., the few layers of atoms that are exposed, and characterization slightly deeper than this, up to a few microns.

Although these dimensions seem incredibly small, it is in this region that materials react with their environment. If you apply glue to a surface, it is applied to this layer, and if this layer falls off easily, then the glue joint fails. Similarly, the exposed atoms are where corrosion begins or a desired catalytic reaction occurs.

The surface is where things happen - both good and bad - and knowledge of surface chemistry is often not intuitive but is vital to much of modern manufacturing.

Can you describe Hiden Analytical’s surface analysis technology?

Hiden specializes in secondary ion mass spectrometry (SIMS), which uses a beam of ions to remove extremely small amounts of material from the surface (often just the uppermost layer of atoms) and then measure them via mass spectrometry.

It is a very sensitive technique, capable of measuring one impure atom out of a million, and can be applied to any solid material. We produce full research-grade instruments in addition to smaller tools for simpler routine measurements, bolt-on analyzers for ion beam microscopes (FIB), and other surface analysis tools, such as those using XPS.

How has this field changed over the last decade?

SIMS was originally developed for measuring the specialized impurities in silicon semiconductors; however, it is now used in a much wider range of industries, including optical coatings, metallurgy, glass coatings and displays, and pharmaceuticals.

Perhaps the largest new sector is the battery industry, as SIMS can easily detect lithium which is a major component of most new consumer batteries.

How has Hiden Analytical reacted to these changes and their challenges?

Hiden has developed a series of smaller, more cost-effective instruments, the Compact and AutoSIMS, that make analysis easier and routine for manufacturing.

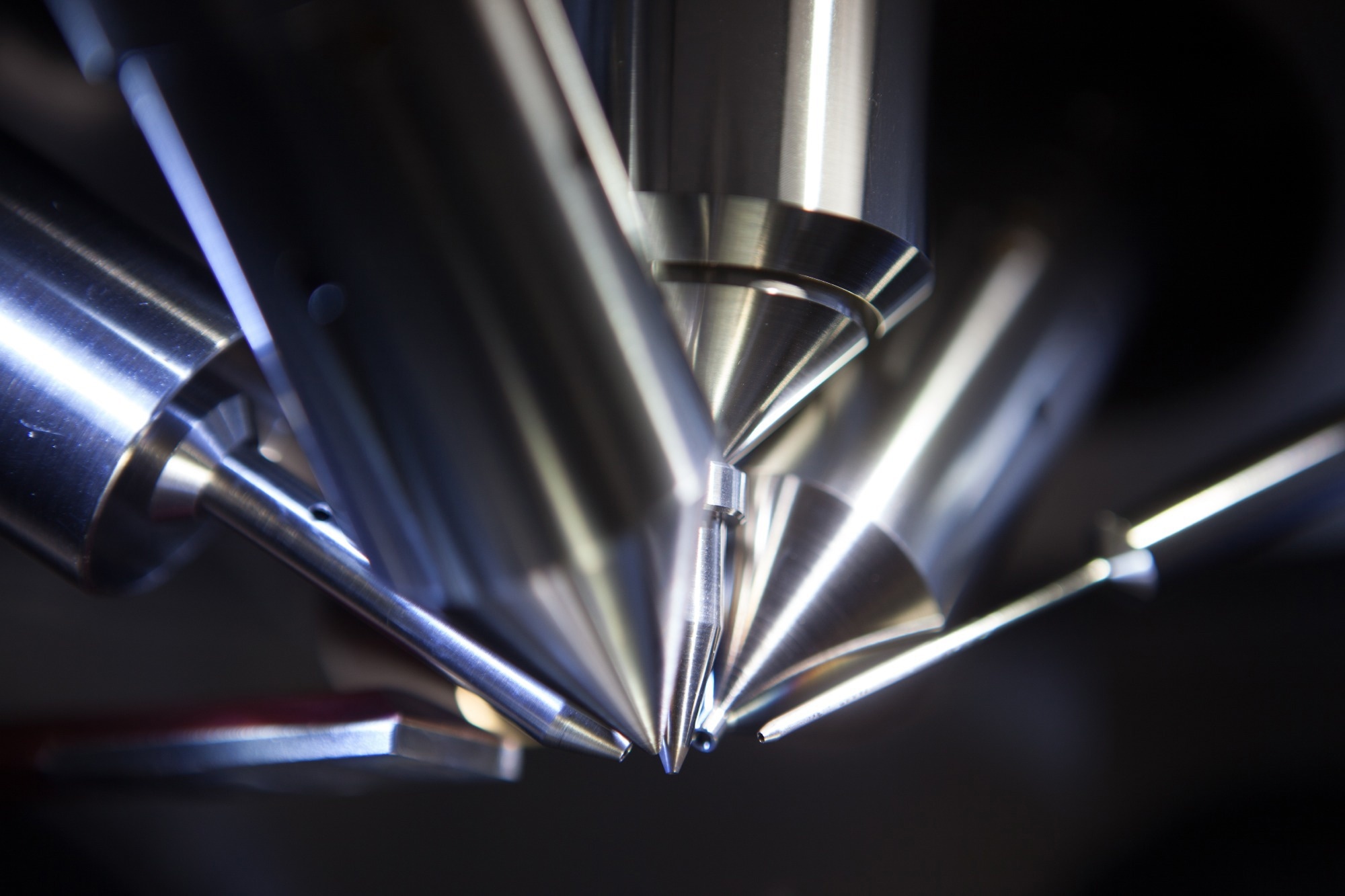

We have also produced highly specialized complex research instruments, such as the Hi5, which is designed to analyze microscopic regions in metals and ceramics and, due to the very limited amount of material available, collect both the positive and negative secondary ions simultaneously. The drive has always been to make the tools simpler to operate and with very high reliability.

How do mass spectrometers work, and how are they used in industry?

Different atoms have different weights. The mass spectrometer essentially weighs the atoms that are injected into it and thus identifies the element. Hiden specializes in the manufacture of quadrupole mass spectrometers; these are relatively small and light and can be easily interfaced into different tools, such as SIMS instruments or gas analyzers.

Some elements exist in different isotopes with atoms that have a different weights but the same chemical property. Uniquely, mass spectrometry can exploit this by using isotopically pure materials as tracers for diffusion and reaction studies in the characterization of fuel cells, semiconductors, and metallurgy.

What types of clients does Hiden Analytical supply mass spectrometers to?

SIMS tools are frequently used in industry and academic research in the hi-tech materials field. Often, they are destined for a specific task, such as measuring surface contamination or semiconductor dopants.

However, many are in general materials research departments in universities where the general-purpose nature of SIMS can be exploited. Surface analysis and microscopy are frequently used as complimentary methods, each supplying solutions to parts of the puzzle.

Image credit: Shutterstock / Yurchanka Siarhei

Why is surface cleanliness important?

We can look at a surface and see that it is shiny, with no obvious contamination. We can even wipe it with a cleaning agent. However, many processes take this a step further and require the surface to be clean at an atomic scale.

A particularly difficult contaminant is polydimethylsiloxane (PDMS), or silicone grease. It occurs in many guises and is used to make a surface shiny (filling in micro scratches), lubricate components, provide waterproofing, and even condition hair. It is also highly mobile, spreading across surfaces quickly and can be extremely hard to remove.

One mono-layer of PDMS will cause an adhesive bond to fail. This could be potentially catastrophic in a bonded aviation component.

In an electrical contact, PDMS decomposes to form glass, and the contact becomes intermittent. Luckily, SIMS is highly sensitive to PDMS and can even measure it by transfer, where a clean foil is pressed against the suspect component, and the foil is subsequently analyzed.

What are some of the problems that can arise from a lack of surface cleanliness?

Semiconductors are highly sensitive to impurities, and SIMS is used to detect and trace the origin of the contamination. This could be as simple as analyzing a particle to determine its origin; for instance, copper and beryllium could indicate abrasion from a spring, and sodium or potassium may show exposure to unclean environments.

What instruments does Hiden Analytical offer to help clients ensure surface cleanliness?

The AutoSIMs and CompactSIMS are ideal tools for assessing cleanliness as samples can be inserted and analyzed on a routine basis. The AutoSIMS can analyze many samples in one loading, allowing staff to work on other jobs.

If the component is too large, the sensitivity of SIMS allows analysis of a test coupon, such as a clean aluminum foil that has been pressed against the surface to transfer some of the surface contamination.

How do SIMS instruments also help clients to deposit thin uniform coatings on products?

Thin layer coatings are very widely used, from coatings on window glass to reflect heat to hard coatings on manufacturing tools like drills. SIM can be used to measure the layer thickness and composition, which in the case of window glass, may contain ten or more layers in a 100 nm coating.

Measuring the coating ensures that the correct formulation and thickness have been applied and that levels of contamination are below accepted levels that may affect performance. If there is a failure of the layer, SIMS can often trace the cause.

Why is SIMS an effective way of quickly determining faults in this process?

SIMS can measure right across the periodic table. It is relatively fast, requires minimal sample preparation, and is, therefore, a good primary analysis technique.

Image credit: Shutterstock / Intothelight Photography

How has the drive for clean energy and more efficient rechargeable batteries changed your clients’ needs?

Over the past decade, due to the drive for clean energy, we have seen more applications for lithium detection due to rechargeable battery use as well as isotopic tracer studies for hydrogen and oxygen transport in fuel cells.

How can the Hiden SIMS tool and the Hiden EQS-FIB detector assist in the battery fuel cell field?

If there was a competition for the ideal element for SIMS analysis, lithium would win. It has two isotopes (making it open to isotopic tracer studies), a high change of ionization when sputtered (super sensitivity), and is not subject to mass interference (confusion) with other species.

Also, while SIMS detects lithium with ease, other techniques (like EDX) show almost no sensitivity to it. This makes SIMS a critical analytical technique for battery research.

What advantages do these tools have over alternative platforms?

The EQS tool for FIB provides microscopists with a chemical element imaging and depth profiling tool that is highly cost-effective and simple to operate. It is also relatively easy to use and is fitted to a platform that many microscopists use daily. The short learning time required to run SIMS on FIB is also a big advantage over a standalone system.

How is this field set to change, and what challenges will your clients face?

The SIMS field is diverging into very expensive general-purpose instruments with extreme detection limits and simpler, more cost-effective tools that are optimized for a particular job.

Our clients are often very busy and are responsible for materials analysis using a variety of techniques. They may not necessarily be an expert in any one technique. Therefore, we aim to make our instruments easy to run and provide data in formats that can be entered directly into a laboratory information management system (LIMS).

Can you explain how Hiden Analytical will help clients tackle these changes?

Hiden has always provided custom instrumentation as well as off-the-peg mass spectrometers. Our ability to use our existing modules to design and build custom SIMS tools and data systems allows us to deliver exactly what the customer requests.

This minimizes complexity and costs (both purchase and ownership) and significantly flattens the learning curve, allowing customers to focus on their core activity.

About Graham Cooke, Principal Scientist at Hiden Analytical

Graham is a physicist, materials analyst and instrument designer, with a strong engineering background, primarily involved with Secondary Ion Mass Spectrometry (SIMS) and other surface analysis and microscopical techniques. He has worked with ultra high vacuum systems and ion optics since 1988 and enjoys developing novel solutions to difficult analytical problems.

This information has been sourced, reviewed and adapted from materials provided by Hiden Analytical.

For more information on this source, please visit Hiden Analytical.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.