AZoMaterials interviews Matt Wilding about how the EP-Replayer enables users to simulate previous etch runs in real time, helping them optimize End Point detection methods, and more.

Can you start by explaining what the EP-Replayer is and how it supports users in optimizing their End Point recipes?

The EP-Replayer is a new feature that lets EPD users play back previous etch data as if it were live, making it easier to create and optimize automatic End Point recipes. Users can define End Point variables in the Methods Recipe file, then replay the data to watch key events get logged and see the expected End Point displayed with precision.

This tool is particularly useful for seeing exactly where chosen settings would trigger End Point detection, allowing users to make adjustments before committing another wafer to etch.

How does the EP-Replayer leverage previous etch data to enable predictive End Point detection and recipe refinement?

Data from the real etch is converted into a Replay file and uploaded to the HAL 10 control unit via our user-friendly web interface, where Replay mode can be easily activated. Once enabled, the Replay file acts as the data source, allowing users to run a Methods Recipe file they’ve configured. The simulated etch then plays out in our MASsoft software, showing live progress and the predicted End Point in real time.

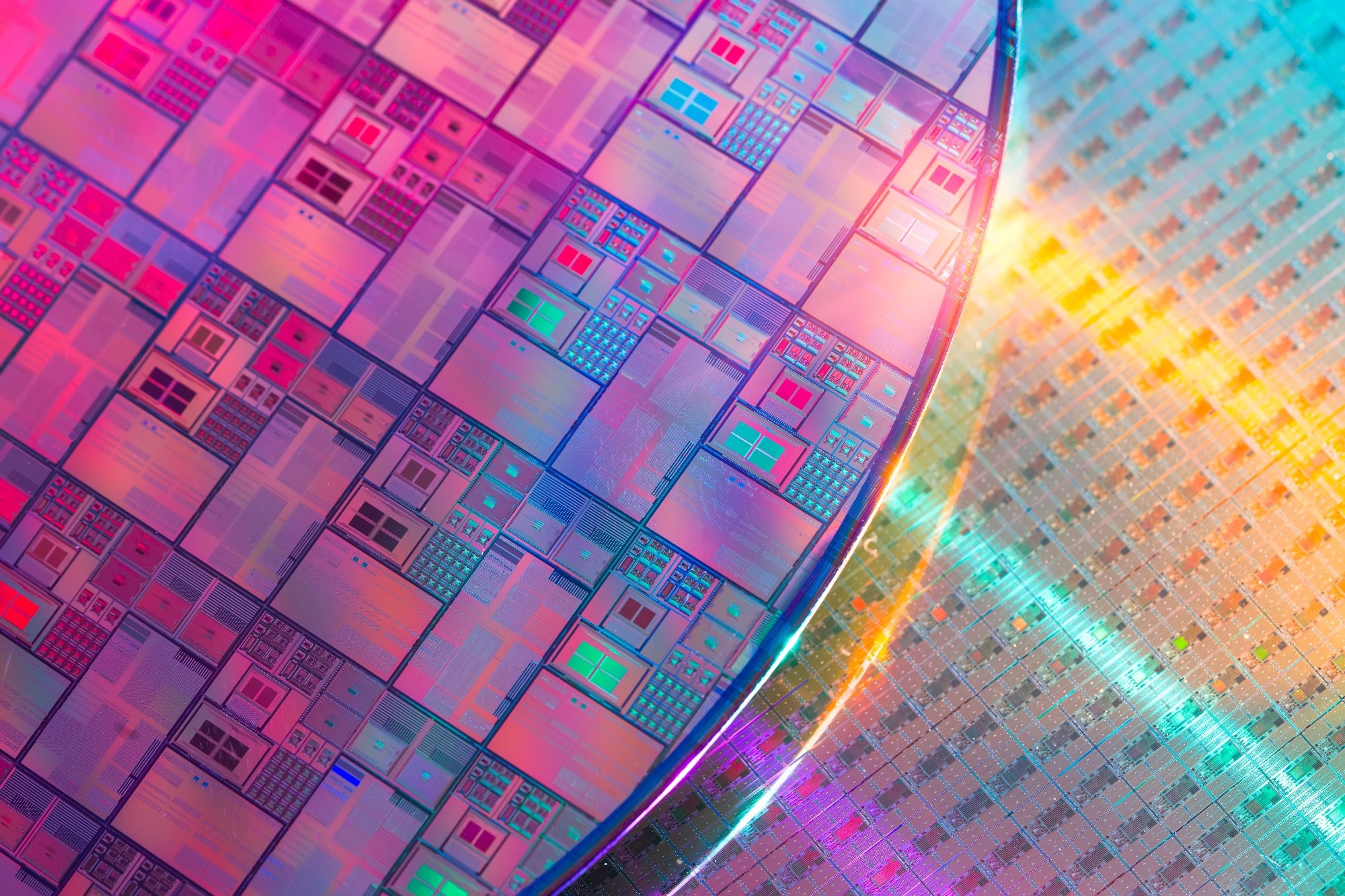

Image Credit: asharkyu/Shutterstock.com

What advantages does the EP-Replayer's real-time reprocessing capability offer when testing or developing End Point methods?

Reprocessing the data and watching these simulated etches back in this way is a huge advantage when setting up a new recipe or improving an existing one. Users can see exactly where End Point would be detected for their given parameters, so they can put wafers into production with high confidence of successful and repeatable End Point runs.

Can you walk us through how the Event Log and Chart Marker graph function during a replay and why they're significant for process analysis?

Just like in a live End Point etch, the Event Log records and timestamps state changes and key count rates throughout the run, such as the End Point signal crossing the defined ‘limit’ value. Meanwhile, the Chart Marker provides a clear visual cue for tracking progress toward the End Point. It overlays a graph onto the etch data to show the current state, making it easy to see when specific criteria are met and the End Point is detected.

How does the EP-Replayer integrate with MASsoft and HAL10, and what are the benefits of this setup for existing IMP-EPD users?

Replay mode is built into the latest HAL10 firmware, and no updates are required for existing MASsoft10 installations. Current HAL10 users can start using this powerful feature right away with a simple firmware upgrade through our web interface.

For added flexibility, we also offer an optional standalone interface unit. This allows users to replay data and fine-tune recipes away from the etch tool, supporting ongoing process development without interrupting live etch operations.

For older installations, a HAL10 unit and the current software package are required, but no additional hardware changes are needed.

How does the EP-Replayer contribute to more sustainable and cost-effective etch processes?

By simulating an End Point run using replayed data from an initial etch, users can greatly reduce the risk of a failed End Point when the recipe is first applied to a live etch - having already seen the predicted outcome.

Replay mode also allows users to test adjustments to End Point recipes, whether for refinement, optimization, or troubleshooting, without consuming additional wafers. This bypasses the trial-and-error cycle of live etches, which can quickly become wasteful and expensive.

We believe the EP-Replayer will make a real difference in helping users cut down on unnecessary wafer use and reduce material waste.

Image Credit: asharkyu/Shutterstock.com

Could you elaborate on how users can trial advanced algorithm features and End Point methods without additional live etches?

Some users may currently rely on basic Methods like simple rising or falling edge detection to find the End Point. However, their process could benefit from more advanced features available in the recipe file, such as Methods that count repeating layers of the End Point material, compare signals against a secondary reference material, or apply data point averaging to minimize false End Points caused by signal variation.

With the EP-Replayer, users can confidently explore and fine-tune these advanced Methods - many of which they may have previously avoided - using replayed data. This opens the door to making processes more reliable and repeatable, all without requiring additional etches during development.

In what ways does the EP-Replayer help reduce the risk of failed End Points or scrapped wafers in high-precision environments?

Currently, users developing or optimizing a process need to rely on a degree of confidence in their interpretations and calculations of the etch data to use the most suitable Method number and parameter values for the End Point they want. Only when the next wafer is run can they see if End Point has been found correctly. An unsuitable method number, value miscalculation, or even just a typo could result in a failed End Point and a costly scrapped wafer.

With the EP-Replayer, users can trial-run their recipes and adjust parameters as often as needed to build full confidence in their End Point setup. This helps ensure the process is robust, repeatable, and as cost-effective as possible.

Looking ahead, how do you see tools like the EP-Replayer influencing the future of process control and optimization in ion beam etching?

Software tools that support automated processes are becoming increasingly valuable, and their role is only set to expand across a wide range of modern industries.

In ion beam etch applications, especially in device fabrication and production settings, we believe that improving etch repeatability, minimizing tool downtime, and reducing unnecessary wafer use are critical goals. Predictive tools like the EP-Replayer can play a key role in achieving these outcomes, making them essential for controlled process development and ongoing improvement both now and in the future.

About the Speaker

Matt Wilding is a Senior Test & Installation Engineer in the Plasma & Surface Analysis Division of Hiden Analytical, based in Warrington, England. With fourteen years at the company, specializing in Ion Milling Probes, he brings expertise in ion beam etch End Point detection used in high specification device production for applications including magnetic thin films, high temperature superconductors and III-V semiconductors. In his role, Matt also provides technical support and training to engineers in advanced manufacturing facilities with the aim of improving their etch processes and productivity.

This information has been sourced, reviewed and adapted from materials provided by Hiden Analytical.

For more information on this source, please visit Hiden Analytical.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.