Scanning Electron Microscopy (SEM) has become a vital tool in materials science, allowing researchers and engineers to explore the intricate structure and surface features of various materials, including polymers.

Polymers, with their diverse applications in areas from packaging to medical devices, display complex microstructures that significantly impact their performance.

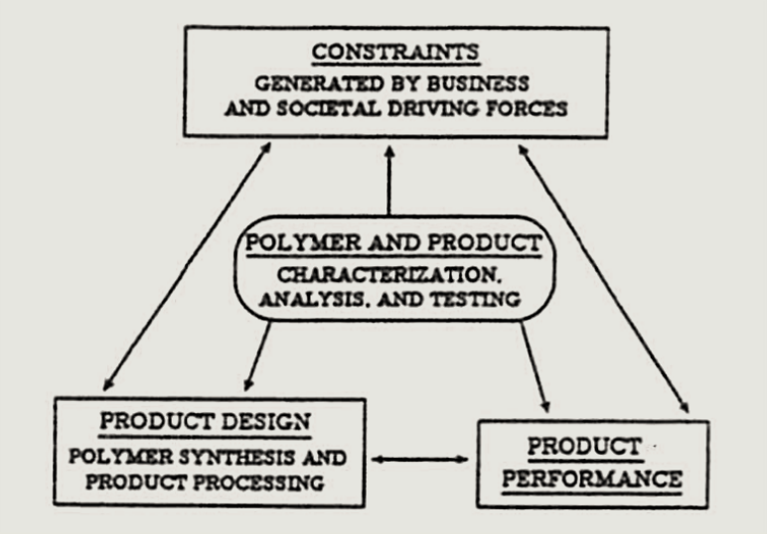

Figure 1. Scheme appeared in 1990 in the preface of the volume "Characterisation of Polymers" of the “Advances in Chemistry” series of the American Chemical Society. The concepts expressed are still extremely current and well represent the key role of polymer characterization.1 Image Credit: COXEM Co. Ltd.

SEM provides a high-resolution, three-dimensional visualization platform for in-depth examination and characterization of micro and nanoscale polymer surfaces and internal structures.

SEM can also reveal how additives, fillers, and reinforcing agents are distributed and arranged within polymers, helping us understand their effectiveness in improving material properties.

Studying these properties necessitates a multidisciplinary approach encompassing rheological, dynamic-mechanical, and morphological aspects.

Controlling the morphology of the material's internal structure through SEM and TEM electron microscopy analysis during the preparation of a polymeric blend is a crucial element in producing new materials, facilitating the identification of necessary actions to enhance the final properties of the developed materials.

The morphological characteristics of the blend can be analyzed by directly visualizing its phases, typically including a continuous phase (the matrix) and one or more dispersed phases representing the minority components.

The shape, size, and distribution of these phases provide insights into the interactions between the polymers and additives in the mixture and the final blend's properties, particularly its mechanical, thermal, and rheological attributes.

Sample Requirements for SEM Analysis

Unlike TEM, which employs transmitted electrons, Scanning Electron Microscope image formation relies on secondary electrons (SE) or back-scattered electrons (BSE). This approach enables the analysis of samples of varying thickness without preparing ultra-thin sections.

Sample sizes can range from a few square millimeters to several square centimeters. Due to SEM's substantial depth of field, samples with uneven surfaces can also be observed by focusing on different planes simultaneously.

To prepare samples for analysis, they can be obtained by fracturing the material after freezing it in liquid nitrogen, allowing the observation of the fracture surface and an exploration of its internal structure.

Since polymers are insulating materials, it is advisable to cover their surfaces with a conductive material such as gold using a sputter coater (such as Coxem SPT-20) or work in low vacuum conditions (LV) to reduce the charge effect caused by the incident electron beam during SEM observations.

Information That Can Be Achieved with SEM

SEM analysis enables the acquisition of three-dimensional images, offering insights into the material's nanoscale characteristics and internal structure.

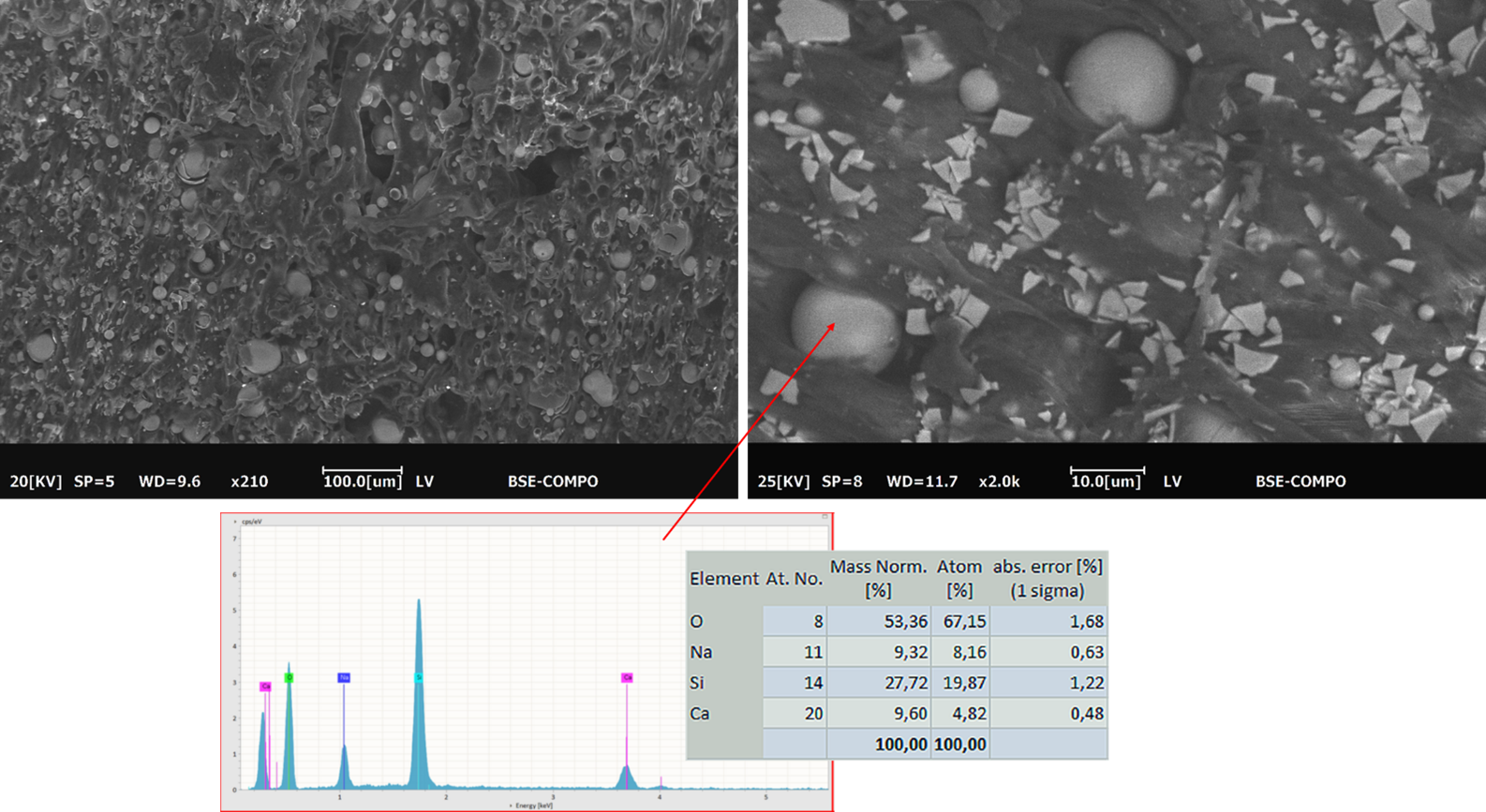

Due to chemical mapping, Energy Dispersive X-ray analysis (EDX) effectively identifies the inorganic fillers within the sample and their distribution within the polymer matrix.

This article provides an overview of the critical aspects that SEM can assist in comprehending regarding your polymer material.

Figures 2-4. SEM-BSE images taken in Low Vacuum mode with Coxem CX-200plus at 20 and 25 kV on a polypropylene (PP) sample added with inorganic fillers. EDS spectrum at 15 kV shows the composition of the filler such as a silicate. Image Credit: COXEM Co. Ltd.

Use of Compatibilizers in Heterogeneous Mixtures

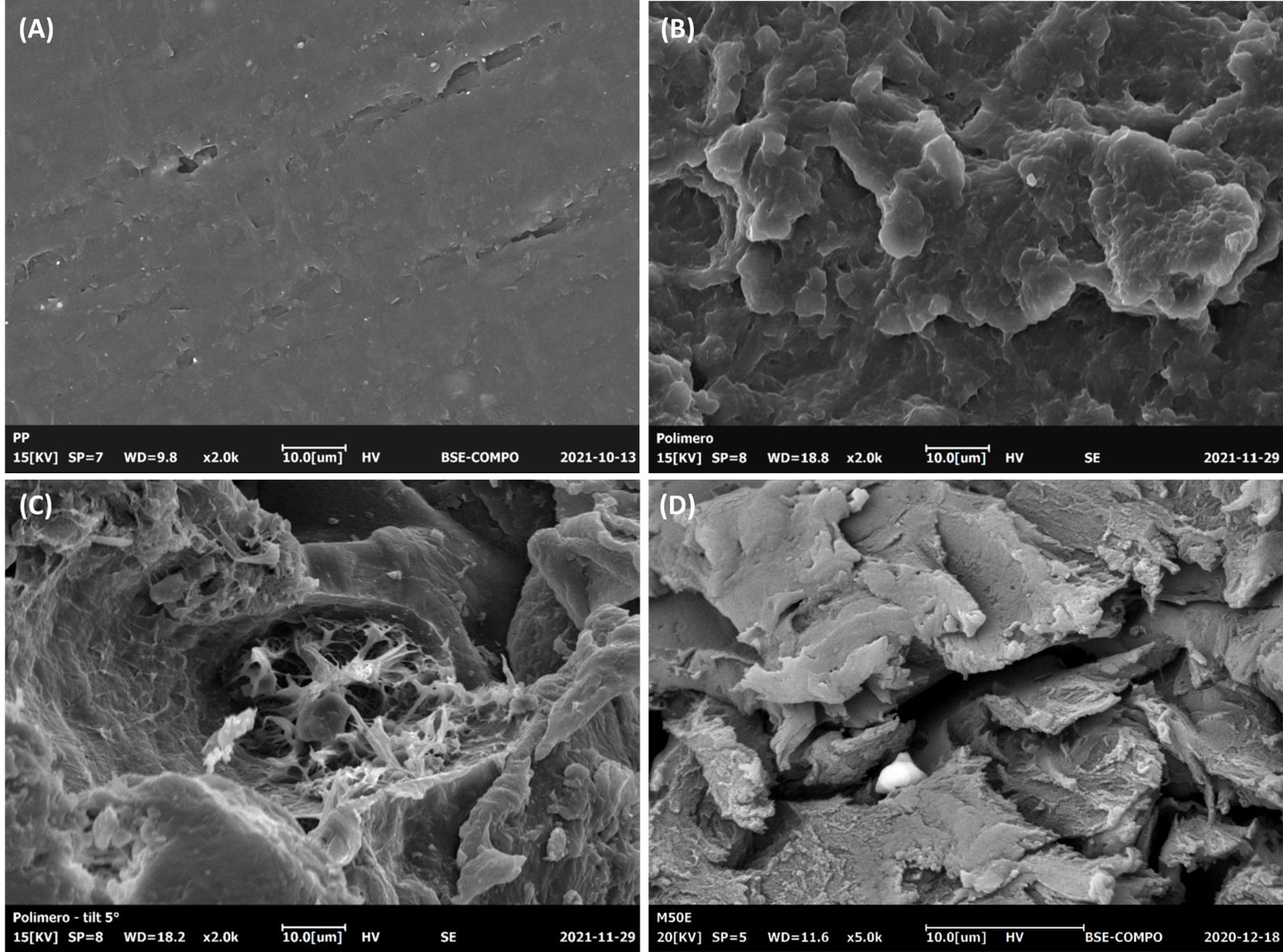

In cases where polymer mixtures are comprised of substances that blend well together, SEM reveals substantial phase homogeneity. Conversely, when immiscible polymers are mixed, SEM uncovers a heterophasic morphology with variable interfacial adhesion, dependent on the presence and concentration of compatibilizer additives.

From an application standpoint, mixtures with phases showing poor adherence to one another exhibit inferior mechanical properties. However, adding a suitable compatibilizer (such as a graft polymer, a block copolymer, or a specific inorganic filler) can significantly alter the material's morphology.

SEM analysis allows for the evaluation of the compatibility of different fractions and the prediction of the material's mechanical and thermal behavior.

The SEM analysis considers morphological parameters like the dispersed phase's shape and diameter and the interphase's thickness, constituting the interface ensuring adhesion between the phases.

Figures 5-8. Polymer blends with different degrees of miscibility: (A),(B) homogeneous phases; (C),(D) heterophasic morphology. (Images taken with SEM Coxem EM-30AXN). Image Credit: COXEM Co. Ltd.

Mechanical Properties: Tensile Tests and Abrasion Tests

When a force (load) acts upon a material, it undergoes deformation, with the type of deformation (elastic, ductile, or brittle) contingent on the applied force's magnitude and the material's inherent resistance.

The tensile test involves gradually applying an increasing axial force to a standardized specimen until it fractures. Some materials break without plastic deformation (brittle), while others break after slow, plastic deformation (ductile).

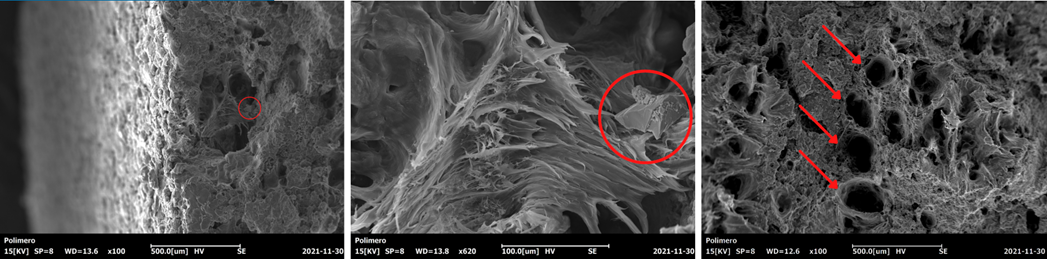

Fractures can occur following a crack's propagation. Therefore, micro-cracks, pores, particle inclusions, or manufacturing/design defects significantly influence fracture propagation.

SEM examination of the fractured surface of a specimen following a tensile test aids in identifying the failure's cause. In Figure 10, for instance, the fracture initiates from inclusion within the material, while Figure 11 reveals numerous cavities in the polymeric matrix that likely formed during production.

These images also allow for visualizing the material's plastic deformation during the tensile test.

Figures 9-11. SEM observation of the fracture surface of a PP specimen after being subjected to a tensile test. (Coxem CX-200plus, 15 kV). Image Credit: COXEM Co. Ltd.

Read the Full App Note Here

Read the Full App Note Here

This information has been sourced, reviewed and adapted from materials provided by COXEM Co. Ltd.

For more information on this source, please visit COXEM Co. Ltd.