In this interview, industry expert Louis Pacheco explores how advanced AFM techniques are transforming the characterization of solid-state polymer batteries, enabling researchers to optimize efficiency, enhance safety, and accelerate the development of next-generation energy materials through nanoscale insight.

Can you explain the role of solid-state polymer batteries in modern energy storage and why their characterization is so crucial?

Solid-state polymer batteries represent a major advancement in energy storage technology. Their key advantages over conventional lithium-ion batteries include enhanced safety through elimination of flammable liquid electrolytes, higher energy density through lithium metal anode compatibility, greater stability with extended battery life, and design flexibility from the lightweight, formable polymer materials.

The characterization of these batteries is crucial because their performance hinges on complex solid-solid interfaces. Understanding ion movement pathways, interface evolution, and local electrical properties directly determines battery efficiency, stability, and safety. Traditional characterization methods often fall short of providing the needed nanoscale insights.

This is where AFM (Atomic Force Microscopy)—and particularly the advanced modes developed by CSI becomes a powerful tool:

- ResiScope enables quantitative resistance measurements at the nanoscale, revealing conductivity pathways and insulating failures across layers. The ResiScope’s 10-decade measurement range and precise current control are essential for quantitative electrical characterization of solid-state polymer batteries, as they allow researchers to accurately probe both highly resistive polymer electrolytes and more conductive interfacial regions—capturing the full spectrum of electrical behavior within a single scan.

- HD-KFM (Kelvin Probe Force Microscopy) maps local surface potential changes, helping identify charge trapping or interface degradation.

- Soft-IC (Soft Intermittent Contact - SIC) is ideal for electrical measurements on soft, fragile polymers without damaging them—perfect for studying polymer electrolytes and interfaces in situ.

By leveraging these techniques, researchers can optimize material formulations, evaluate degradation mechanisms, and engineer more efficient and stable battery designs. In short, precise nanoscale characterization is not just beneficial, it’s critical to the successful development of solid-state polymer batteries.

By providing these comprehensive nanoscale insights, we enable researchers to optimize material formulations, understand degradation mechanisms, and engineer more efficient battery designs, directly addressing the needs communicated by professionals in this field.

What are the primary challenges in analyzing solid-state battery materials, and how does AFM help address them?

Analyzing solid-state battery materials presents several significant challenges that conventional techniques struggle to address. These include high interfacial resistance between components, nanoscale heterogeneity that affects performance, and an extraordinarily broad range of local conductivities, from highly insulating polymer electrolytes to relatively conductive interfaces and electrodes.

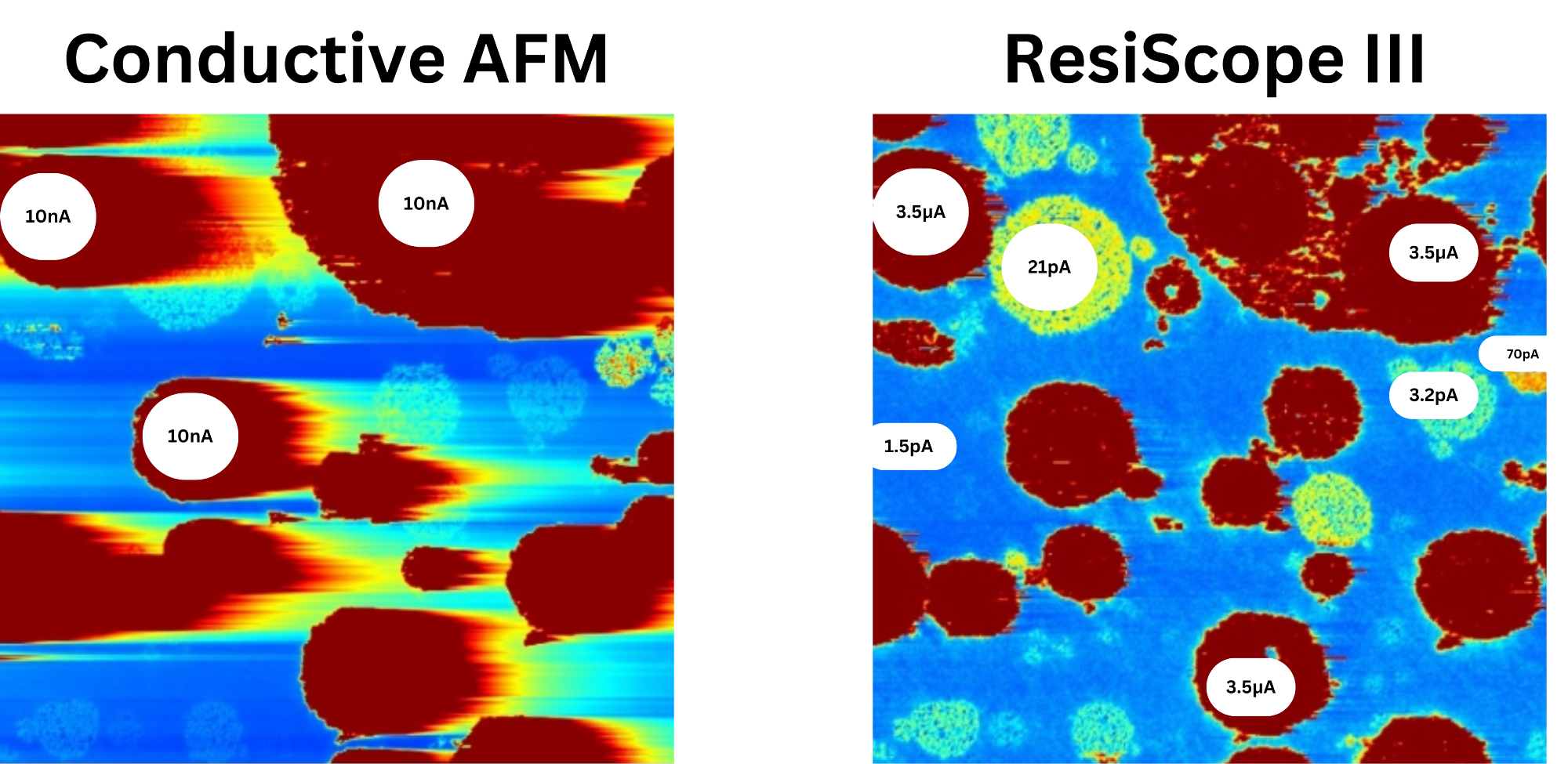

Traditional characterization methods like Conductive AFM (C-AFM) face fundamental limitations in this context. They typically offer limited sensitivity and restricted current range, making it impossible to fully characterize these complex systems in a single measurement. Additionally, the contact mode operation of C-AFM can damage delicate polymer surfaces, potentially introducing artifacts or altering the very properties being measured.

Our advanced AFM modes directly address these challenges. ResiScope enables quantitative resistance mapping over an unprecedented 10 decades, capturing the full spectrum of electrical behavior from pA to μA currents. HD-KFM provides nanoscale surface potential imaging with superior spatial resolution (< 10 nm) and voltage sensitivity (< 3 mV). When combined with Soft-IC, these techniques allow low-force electrical probing that preserves sample integrity.

This comprehensive approach makes our AFM system essential for understanding the degradation mechanisms, optimizing material interfaces, and guiding the design of next-generation solid-state batteries. By providing non-destructive, high-resolution characterization that simultaneously maps topography, resistance, current distribution, and surface potential, we reveal critical correlations between structure and function at the nanoscale—precisely where battery performance is determined.

You have integrated the Soft Intermittent Contact and ResiScope into a single system to enhance battery analysis. How do these techniques improve upon conventional AFM methods like Conductive AFM and SSRM?

Our integration of Soft Intermittent Contact (Soft-IC) with ResiScope represents a significant advancement over conventional AFM techniques like Conductive AFM (C-AFM) and Scanning Spreading Resistance Microscopy (SSRM), particularly for challenging solid-state battery materials.

Conventional C-AFM and SSRM face fundamental limitations: they operate in continuous contact mode, applying constant force and friction that often damages soft polymer electrolytes or delicate interfaces. Additionally, their passive fixed-gain amplifiers restrict measurement range, typically to just 3-4 orders of magnitude per scan.

Our Soft-ResiScope integration overcomes these limitations through two complementary innovations. First, Soft-IC eliminates frictional effects by operating in intermittent contact mode, touching the surface only momentarily to acquire electrical measurements without lateral forces. This ensures non-destructive analysis of polymer electrolytes while preserving surface structure.

Image Credit: CSInstruments

Second, ResiScope extends measurement capabilities dramatically through its active linear gain controlled by a processor. This enables resistance measurements across 10 orders of magnitude (100 Ω to 1 TΩ) within a single scan, capturing both highly insulating regions and conductive phases simultaneously. Additionally, ResiScope's current control prevents tip and sample damage on highly conductive areas, a common failure point in conventional systems.

The result is a system delivering exceptional resistance range and current sensitivity (50 femtoamperes to 100 milliamperes), with controlled vertical tip oscillation that preserves delicate battery interfaces while maintaining precise electrical characterization. This provides a more complete, quantitative approach to characterizing solid-state battery materials, making it invaluable for both fundamental research and applied development.

ResiScope III: Ultimate Electrical Characterization | Beyond Traditional SSRM & C-AFM

Video Credit: CSInstruments

The ability to switch seamlessly between Soft ResiScope and HD-KFM III is mentioned as a key advantage. How does this multimodal approach enhance battery material analysis?

This combination allows researchers to correlate local electrical conductivity (via ResiScope) with surface potential and work function variations (via HD-KFM III) at the exact same location and under identical conditions.

This integration is particularly valuable for solid-state battery research because it allows researchers to:

- Distinguish between ionic and electronic conduction paths—critical for understanding transport mechanisms in complex electrolytes.

- Identify charge accumulation zones at solid-solid interfaces that may indicate incipient degradation.

- Track electrochemical changes at the nanoscale through multiple charge-discharge cycles.

- Validate material uniformity and performance across electrode-electrolyte interfaces.

- Correlate structural features with electrical performance directly.

By providing this comprehensive perspective without changing cantilevers or relocating samples, researchers gain unprecedented insights into why certain material combinations outperform others. This guides targeted optimization of battery components, accelerating development cycles, and improving outcomes.

In essence, this multimodal approach functions as a multidimensional map of battery functionality, revealing not just what's happening but why it's happening at the most fundamental level, precisely the insights needed to advance solid-state battery technology.

How do AFM findings contribute to improving battery efficiency, lifespan, or safety?

Advanced AFM techniques provide critical insights that directly translate to battery performance improvements across multiple dimensions. Our high-resolution electrical characterization reveals the nanoscale mechanisms that determine overall battery function.

For efficiency enhancement, AFM findings identify ion transport bottlenecks that limit power delivery. By mapping current distribution and resistance variations at interfaces, researchers can identify exactly where charge transfer is impeded.

HD-KFM and ResiScope reveal local conductivity and potential variations, helping researchers identify resistive zones or poor contact areas that limit charge transport. Optimizing these regions leads to faster ion/electron movement and higher energy output.

Regarding lifespan extension, our non-destructive techniques, such as Soft-IC, enable tracking of the same battery regions through multiple charge-discharge cycles, revealing early-stage degradation mechanisms. The visualization of lithium-ion pathway formation during cycling provides direct evidence for performance differences between material combinations, guiding the development of more durable battery compositions.

Safety improvements stem from the ability to detect potential failure points at the nanoscale. By identifying regions prone to dendrite formation through high-resolution current mapping using Soft-ResiScope, researchers can redesign materials to mitigate these risks. These comprehensive insights drive holistic improvements across all aspects of battery performance, accelerating the development of next-generation energy storage solutions.

Battery degradation is a major concern in energy storage. Can these AFM techniques help detect early signs of degradation or failure in solid-state batteries?

These non-destructive techniques excel at monitoring the same areas through multiple cycles, detecting subtle changes in resistance, current flow, and surface potential that precede visible degradation.

Our advanced AFM modes, such as ResiScope, HD-KFM, and Soft-I,C allow researchers to monitor key degradation indicators at the nanoscale, long before they manifest at the macroscopic level:

- ResiScope reveals subtle changes in local conductivity, helping to identify loss of ionic/electronic pathways or the growth of resistive interphases, both of which can signal early-stage degradation.

- HD-KFM III detects surface potential shifts, highlighting charge accumulation, delamination, or electrochemical imbalances at interfaces, often precursors to performance fade or failure.

- Soft-IC enables non-destructive probing of delicate polymer electrolytes and interfaces, making it possible to track mechanical fatigue, material creep, or microcracks that might otherwise go unnoticed in traditional contact-mode techniques.

By enabling this early detection of degradation precursors, our AFM tools help researchers identify specific failure mechanisms, refine material formulations to address them, and engineer longer-lasting, more robust solid-state batteries. This accelerates development cycles by providing immediate feedback on design modifications and material improvements.

What role do these AFM techniques play in the development of next-generation energy materials?

Our advanced AFM techniques serve as foundational enabling tools in the development of next-generation energy materials, extending well beyond solid-state batteries to impact multiple emerging energy technologies.

By providing real-time feedback during material design and offering actionable insights into nanoscale mechanisms, these techniques accelerate the transition from laboratory innovation to scalable, high-performance energy technologies. The multi-parameter correlation capabilities—linking structure, resistance, current flow, and surface potential—provide a comprehensive understanding that guides rational material development.

For solid-state batteries, as we've discussed, these techniques reveal ion transport pathways and interface properties that determine overall performance. But these same capabilities apply equally to other critical energy technologies.

In solar cell development, researchers use ResiScope and HD-KFM to investigate charge separation efficiency, carrier transport mechanisms, and degradation pathways. The ability to correlate nanoscale electrical properties with overall device performance helps optimize both organic and inorganic photovoltaic architectures.

For fuel cells and supercapacitors, our techniques provide insights into electrode-electrolyte interfaces that control energy conversion and storage capabilities. In flexible and wearable energy systems, the non-destructive nature of Soft-IC enables characterization of delicate materials and interfaces that must maintain functionality under mechanical stress.

The fundamental understanding provided by these techniques, revealing structure-property relationships at the nanoscale, helps researchers design more efficient, durable, and sustainable energy materials across the entire spectrum of emerging technologies. By identifying performance-limiting factors with precision, these tools guide targeted optimization efforts and accelerate development cycles.

This ultimately contributes to addressing our world's evolving energy needs through advanced materials engineered at the nanoscale, where their functional properties are fundamentally determined.

About Louis Pacheco

Louis Pacheco is Senior Application Engineer and Product Manager at CSInstruments, where he has driven advancements in atomic force microscopy for 19 years. He plays a key role in developing cutting-edge solutions for scientific and industrial research across global markets.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.