Accurate particle size analysis is crucial in research, development, and manufacturing across a wide range of industries. From pharmaceuticals to paints and coatings, particle size affects key properties such as dissolution rate, stability, color, texture, and flowability. Selecting the correct sizing technique ensures not only product quality but also compliance with regulatory requirements.

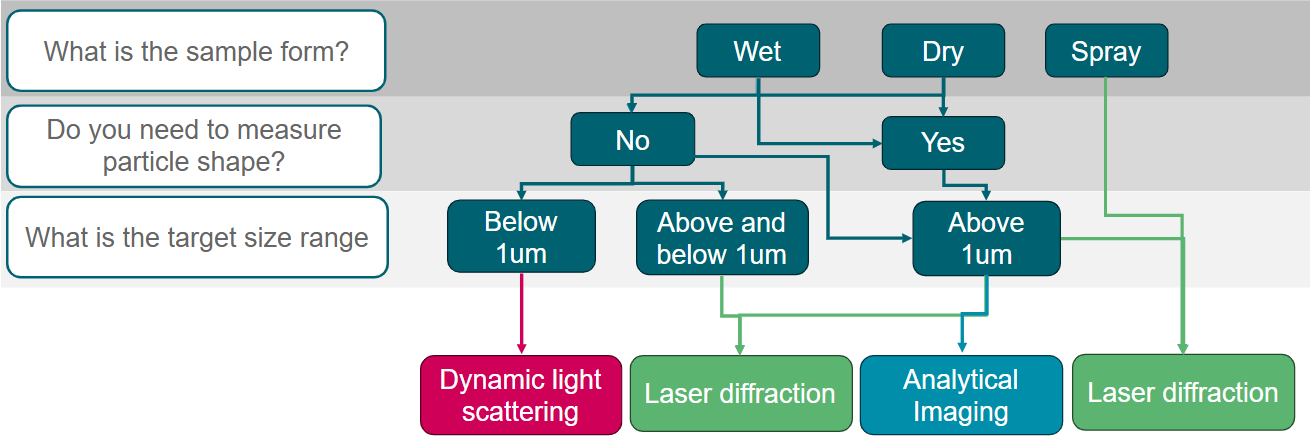

When choosing a particle sizing technique, start by defining your goals. What do you want to achieve? Whether it's detecting agglomerates or controlling the fine particle fraction, your objectives will guide you to the right techniques with the necessary sensitivities.

Even if you're limited by the techniques available, understanding their strengths and weaknesses ensures you get realistic and robust results. Key factors to consider include the size range the instrument can measure, the types of samples it can handle (dry powders, suspensions, emulsions, and sprays), and the technique's sensitivity (number or volume-based). Also, think about the accuracy and precision you can expect.

Practical considerations are just as important. How many measurements do you need to perform each day? How long will each measurement take? How much sample dilution is required? And do you need additional information, like particle shape?

This guide explores the most widely used particle sizing methods and offers insight into how to select the best approach for your materials and objectives.

Image Credit: Malvern Panalytical

Common Particle Sizing Techniques

1. Laser Diffraction

Laser diffraction is one of the most widely used techniques due to its broad dynamic range and ease of use.

- How it works: Measures the angular variation in intensity of light scattered as a laser beam passes through a dispersed particulate sample.

- Typical size range: ~0.01 µm to 3500 µm

- Sample types: Powders, emulsions, suspensions, sprays

- Strengths:

- Rapid analysis with high reproducibility

- Handles a wide range of sample types and sizes

- Suitable for real-time monitoring in production (PAT applications)

- Limitations:

- Assumes spherical particles for calculation

- Limited in resolving closely spaced size distributions

Example applications: Pharmaceuticals, paints and pigments, food, building materials, polymers

2. Dynamic Light Scattering (DLS)

DLS is the technique of choice for measuring nanoparticles and colloidal suspensions.

- How it works: Analyzes fluctuations in the intensity of scattered light caused by Brownian motion of particles in suspension.

- Typical size range: ~0.3 nm to 10 µm

- Sample types: Nanoparticles, proteins, liposomes, polymers in solution

- Strengths:

- Highly sensitive to small changes in particle size

- Fast and non-destructive

- Ideal for stability studies and formulation development

- Limitations:

- Less effective for polydisperse or non-spherical systems

- Requires dilution and clean sample prep

Example applications: Biopharmaceuticals, drug delivery systems, cosmetic emulsions, polymer dispersions

3. Imaging Techniques

Imaging techniques provide visual and quantitative information about particle size and shape.

- How it works: Captures high-resolution images of particles, then analyzes them using software to determine size, shape, and other morphological parameters.

- Typical size range: ~1 µm to several mm

- Sample types: Irregularly shaped particles, fibers, aggregates

- Strengths:

- Provides detailed shape information (e.g., aspect ratio, roundness)

- Enables differentiation between similar-sized particles based on morphology

- Useful for troubleshooting or product development

- Limitations:

- Slower than other methods

- Requires more complex analysis and interpretation

Example applications: Pharmaceutical powders, abrasives, food ingredients, mineral samples

Other Particle Sizing Methods

In addition to the primary techniques above, other methods may be relevant depending on the application:

- Sieving: Simple and cost-effective for coarse particles, often used in bulk material processing.

- Sedimentation: Based on Stokes’ law, good for larger, denser particles.

- Electrozone sensing (Coulter Principle): Measures changes in electrical resistance as particles pass through a small aperture—common in cell counting.

Factors to Consider When Choosing a Technique

Selecting the right technique depends on multiple variables:

Source: Malvern Panalytical

| Consideration |

Why it Matters |

| Particle size range |

Different techniques have different operational ranges. |

| Sample type |

Liquid, dry powder, emulsion, or aerosol? |

| Accuracy & resolution |

How precisely do you need to distinguish sizes or shapes? |

| Throughput & speed |

High-volume lab vs. occasional measurements? |

| Regulatory standards |

Some industries require validated, standardized methods. |

| Budget & resources |

Instrumentation, training, and maintenance costs. |

Expert Perspective

There’s no one-size-fits-all solution when it comes to particle sizing. Each technique offers unique insights. Often, a combination of methods gives the clearest picture of a material’s properties.

Dr. Anne Virden, Product Manager, Analytical Imaging, Malvern Panalytical

Dr. Virden emphasizes that understanding not just how each technique works but also when and why to use them is key to achieving reliable results and informed process decisions.

Conclusion

Whether you're formulating a pharmaceutical tablet, developing a coating, or controlling the consistency of a food product, choosing the right particle sizing technique can make or break your outcome. By aligning the method with your material characteristics, goals, and process requirements, you can ensure precision, consistency, and regulatory compliance.

Malvern Panalytical offers a full suite of particle sizing solutions, from laser diffraction to nanoparticle tracking, supported by expert consultation and ongoing training.

Particle Size Analyzers from Malvern Panalytical

This information has been sourced, reviewed and adapted from materials provided by Malvern Panalytical.

For more information on this source, please visit Malvern Panalytical.