Light scattering has long stood as a cornerstone technique in the characterization of particles across a wide range of scientific disciplines. From pharmaceuticals to food production, and from nanomedicine to environmental analysis, its versatility and precision make it indispensable. As technological innovation accelerates, new challenges and opportunities are reshaping how light scattering is applied, particularly as automation, AI, and advanced detection methods come to the forefront.

In this interview, AZoMaterials speaks with experts from Malvern Panalytical, a company at the forefront of light scattering innovation, to explore the technique's current landscape and future potential.

Light scattering has been a fundamental tool in particle characterization for decades. Can you give us a brief overview of how this technique works and why it is so essential?

Light scattering is a versatile and non-invasive technique used to characterize dispersed particles. There are differences in how individual light scattering techniques work, but the same fundamental principle applies – namely, when a beam of light interacts with dispersed particles, it scatters in various directions.

Take laser diffraction, for example, which is used to obtain particle size information from the sub-micron scale to several millimeters. In this case, we are interested in the time-averaged angular dependence of scattered light, which depends on the dispersed particles' sizes and size distribution. By measuring the intensity of scattering light across a wide angular range, it is possible for a particle size distribution (PSD) to be calculated.

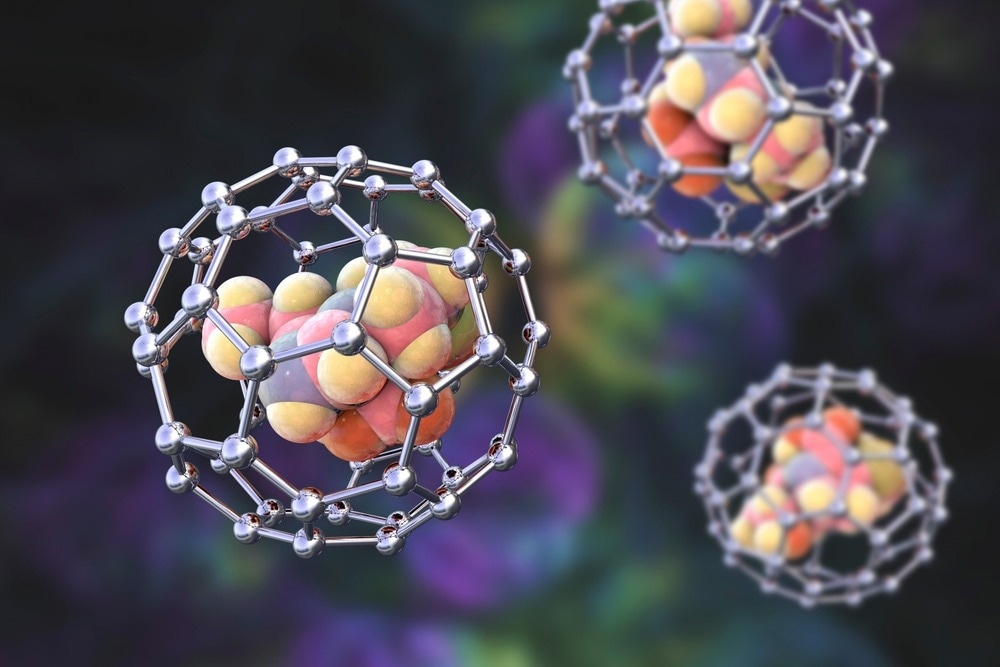

Image Credit: Kateryna Kon/Shutterstock.com

On the other hand, Dynamic Light Scattering (DLS) is used for nano-scale particles (a few microns to nanometres). Scattering from nanoparticles is still angular dependent, to a greater or lesser degree, but instead of looking at the angular data, we are interested in the time dependence of the scattering. We measure the scattering intensity over time at one or more specific angles – the angles used depend on the information required. How quickly or slowly the scattering intensity varies over time relates to the Brownian motion of the dispersed particles. Therefore, this gives us a measure of their size and distribution width (polydispersity), and secondary analysis can provide size distributions.

Light scattering is essential because it provides absolute measurements without the need for external calibration standards, making it highly reliable for characterizing a wide range of sample types. Determining properties such as particle size, shape, and molecular weight is key to unlocking an understanding of how materials and processes will perform in fields as diverse as pharmaceuticals, battery manufacturing, and mining.

Malvern Panalytical has long been a pioneer in the field of light scattering, particularly with instrument ranges like Mastersizer (for laser diffraction) and Zetasizer (for light scattering).

What are some of the most significant advancements in light scattering techniques in recent years, and how have they improved particle characterization?

One area of significant advancement has been in computer processing capabilities, which has significantly improved data handling in light scattering techniques. Lights scattering systems, like the Mastersizer, leverage powerful processors to analyze larger datasets with greater speed and accuracy; and the possibility of using cloud computing will expand processing power even further. This capability is crucial for studying complex samples and obtaining detailed particle size distributions. Enhanced data processing also supports intelligent algorithms that can differentiate between subtle variations in particle size distributions, which then provides deeper insights into sample properties.

The adaptive measurement types from Malvern Panalytical - Adaptive Correlation on the Zetasizer Advance series and Adaptive Diffraction on the Mastersizer 3000+ dynamically adjust measurement parameters based on real-time data, optimizing the accuracy and reliability of results. These innovations ensure that our instruments provide the most accurate and detailed particle characterization of your sample and give our users confidence in their data.

Other new approaches to conducting light scattering measurements have been introduced in the past decade. Multi-angle dynamic light scattering (MADLS) used by the Zetasizer is significant. MADLS measures scattered light at multiple angles, providing a comprehensive analysis of particle size distributions in polydisperse samples as well as more precision for monomodal samples. This approach enhances the accuracy of measurements and is particularly useful for complex samples with a wide range of particle sizes.

And then you have automation and artificial intelligence, which are starting to be incorporated into mainstream light scattering instrumentation. Automation is about partly enabling higher throughput so you can test more samples and reduce the requirement for operator input, which can be a significant source of uncertainty. AI, on the other hand, opens up many exciting possibilities for data handling and gaining insights about your data.

One of the challenges in light scattering is accurately analyzing polydisperse or complex systems. What strategies or innovations are helping to overcome these limitations?

Analyzing polydisperse or complex systems can be challenging, and we are increasingly seeing samples become more complex in this way. Fortunately, innovations made by Malvern Panalytical, such as multi-angle dynamic light scattering (MADLS) and advanced image processing techniques, are helping to address these limitations. MADLS, for instance, provides a more comprehensive analysis by measuring scattered light at multiple angles, improving the accuracy of size distribution in polydisperse samples and providing a more accurate reflection of the sample's size distribution by removing angular bias. Experimental platforms combining light scattering with image sensors have shown promise in analyzing complex systems.

How do emerging fields like nanotechnology and biopharmaceuticals influence the evolution of light scattering methods?

Light scattering techniques such as DLS have been very important in characterizing some of the recent, emergent advances in, for instance, nano-medicines – not only for their basic size but also in understanding their formulation stability and bioavailability. These systems are vastly more complex than typical emulsions or dispersions, as they are also functional. They must be in the correct “arrangement” and maintain that structure for them to perform. This drives us to look at how we can best supplement the light scattering data to provide those increasingly important insights into these new application areas.

You mentioned automation and AI as two areas of advancement for light scattering. Can you elaborate on how you see these technologies shaping the future of light scattering in research and industry?

One recurring trend we have observed is a progressive deskilling of users of light scattering systems. Not every user wants or has the time to become an expert on the Mastersizer or Zetasizer, for example. Researchers and industrial scientists face increasing demands on their time and the resources available to them, and many want light scattering instruments to do as much of the ‘heavy lifting’ as possible when it comes to the measurement workflow. Automated solutions, such as the Zetasizer Sample Assistant, can take care of sample handling and presentation, while tools such as Mastersizer’s SOP Architect can help users develop their method.

Automation and AI are also helping with the growing need for high sample throughput and extensive data sets. Customers need large quantities of data they can trust, ensuring quality and quantity are met.

What are some of the most unexpected or groundbreaking applications of light scattering that have emerged recently?

One of the great things about light scattering is that it applies to most industries and fields of research, and we are reminded of this time and again in the fascinating, and sometimes unexpected, work performed by our customers.

One notable application is vaccine development, particularly during the COVID-19 pandemic, where light scattering was crucial. The Zetasizer became an essential tool for vaccine developers, helping them analyze the size and stability of nanoparticles used in vaccines. This technology ensured that the vaccines were effective and safe, contributing significantly to the rapid development and deployment of COVID-19 vaccines.

Image Credit: peterschreiber.media/Shutterstock.com

We are also seeing more interest in microplastics, and for good reason. Microplastics are tiny pieces of plastic less than 5 mm in size, and they originate from everyday items like single-use plastics, clothing, and personal care products. These plastics enter the environment and food chain, posing risks to human health and the ecosystem. The MOMENTUM project in the Netherlands is using light scattering to characterize microplastics. By employing the Mastersizer, its researchers can size samples and create "Microplastics Passports," which help track and understand the impact of these pollutants.

One final example of an exciting new application is precision fermentation. This involves using engineered microbes - such as bacteria, yeast, or fungi - to produce functional ingredients like proteins for meat or dairy substitutes. This method is gaining traction as the world seeks to reduce the environmental impact of traditional agriculture and enhance the resilience of the global food supply. Light scattering is vital in this process for controlling the size of particles to ensure food products have a consistent structure and are enjoyable to eat. It helps assess protein stability to prevent aggregation and potential yield loss.

In terms of measurement accuracy and sensitivity, what are the key areas where light scattering technology is still evolving?

Light scattering technology is continually evolving, even after decades of sustained development. A few key areas stand out in terms of measurement accuracy and sensitivity.

One of those key areas is improvements in detector technology, which have greatly enhanced the accuracy and sensitivity of light scattering measurements. Modern detectors, such as high-sensitivity CCD cameras, avalanche photodiode (APDs), and photodiode arrays, are now more efficient at capturing scattered light signals. These advancements enable better detection of low-intensity signals, which are crucial for analyzing small particles or low-concentration samples.

Malvern Panalytical is improving the sensitivity of laser diffraction for coarse particles. The Mastersizer 3000+ has introduced innovative features like Size Sure, using Adaptive Diffraction, which helps with this. This is particularly important for industries such as battery manufacturing, where coarse particles can cause short-circuiting of the cathode and anode.

The field of light scattering is also advancing through the development of best practices for method development and measurements. For example, the ISO/TS 5973 publication provides comprehensive guidelines for laser diffraction measurements, covering everything from sample preparation to data interpretation. This standard helps ensure that measurements are consistent and reliable, which is essential for achieving high accuracy and sensitivity in light scattering experiments.

As industries push for real-time, in-line particle characterization, what challenges and opportunities does this present for light scattering techniques?

In-line particle characterization is becoming increasingly more common in industry as they look for more immediate feedback on their processes and try to reduce the need for laboratories to perform off-line characterisation, which can be costly. This pivot from off-line to in-line characterization presents light scattering with some challenges. With each challenge comes the opportunity to further develop light scattering techniques and leverage other technologies to find a solution.

One of the primary challenges is ensuring equivalence between inline and offline characterization methods. You might be interested in comparing data from different supply chain states, such as during processing using in-line methods and quality control (QC) using off-line methods. In the ideal scenario, you will want the results from the techniques to agree. However, the two approaches, off-line and in-line, typically necessitate methodological differences, such as optical setup, which can impact the recorded particle size distribution (PSD). For example, there is the opportunity to sequentially use different wavelength light sources to extend your measured size range in off-line situations, where the sample can be recirculated; this is not really possible for in-line sampling.

Handling high-concentration samples presents another challenge. In many industrial processes, the particle concentration can be high, leading to issues with multiple scattering, where particles interfere with each other's scattering signals. For offline or at-line measurements, the solution would be to dilute the sample, but for inline measurements, this is not an option. This can complicate the analysis and reduce the accuracy of particle size measurements. Techniques like adaptive diffraction and advanced algorithms are being developed to mitigate these effects and improve measurement reliability.

Detecting small numbers of coarse particles is critical in industries such as ink and paint manufacturing, where even a few large particles can significantly impact product quality. A fast and comprehensive analysis is required to ensure that coarse particles are not missed.

For researchers and scientists looking to advance in this field, what areas of study or innovation do you think hold the most promise?

As with many other fields, artificial intelligence undoubtedly holds the most promise. We already see how it shapes our ability to deliver useful tools to provide higher-quality data from instruments in less time. I am so excited to see how Artificial Intelligence could be used in the future to bring the data from light scattering together with other characterization techniques to develop an even deeper understanding of how samples behave or could be predicted to behave.

Where can readers find more information?

Please provide links to any materials that may be relevant to our audience.

Light Scattering - An Overview | Malvern Panalytical

Mastersizer | Laser Diffraction Particle Size Analyzers | Malvern Panalytical

Zetasizer | Expert Light Scattering Instruments | Malvern Panalytical

About Darrell Bancarz

Darrell Bancarz is a seasoned Product Manager specializing in nanomaterials at Malvern Panalytical, based in Worcestershire, England. With over twenty years at the company, he brings deep expertise in scientific instrumentation and materials analysis. Prior to his current role, Darrell served as Applications Services Manager, contributing to customer-focused solutions and technical support. His work supports innovation in materials science and advanced manufacturing.

About Dr. Anne Virden

Dr. Anne Virden is a Product Manager in Malvern Panalytical’s Micro-Micromaterials group, based at the company’s Malvern headquarters. She oversees products designed to measure particle size, shape, and chemistry in the micron range, using techniques such as laser diffraction, analytical imaging, and Raman spectroscopy. With more than 15 years of experience analyzing particles across diverse application areas, she applies her extensive expertise to drive the development and innovation of Malvern Panalytical’s micro materials portfolio.

About Malvern Panalytical

The integration of Malvern Panalytical, Micromeritics, and SciAps.

Together, we are a powerful and highly complementary combination of market-leading technologies.

This information has been sourced, reviewed and adapted from materials provided by Malvern Panalytical.

For more information on this source, please visit Malvern Panalytical.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.