Prepregs are reinforcement materials that have been pre-impregnated with either thermoplastic or thermoset resins. They are used in high-performance applications where mechanical properties and low weight are prioritized over cost. They are most commonly reinforced with high-end epoxy resins and advanced fibers.

A prepreg combines a partially cured polymer matrix, such as epoxy or phenolic resins, with reinforcing fibers. Common fiber types include glass, carbon, and aramid, while basalt is a notable non-fibrous alternative.

Image Credit: Galaxy Scientific Inc

Overview of Prepregs

Prepregs are used in high-performance applications across the composites industry and various other sectors, such as aircraft flooring and interiors, or flame-retardant laminates.

They are particularly advantageous due to their good fatigue, resistance to environmental weathering and corrosion, high specific modulus and strength, and their controllability of laminate thickness and fiber volume fraction, amongst other properties.

These attributes make prepreg materials particularly suitable for applications requiring electrical insulating properties. For example, prepregs are often used as insulating materials in electrical machines and transformers.

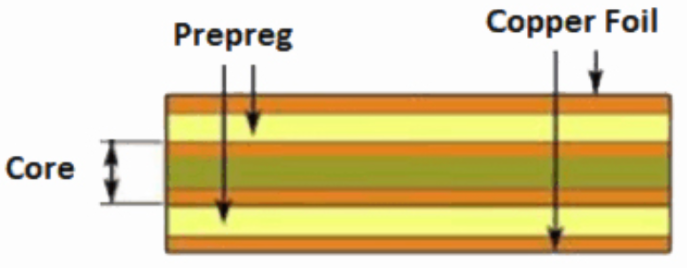

Prepregs are sometimes used as an intermediate layer in multilayer circuit boards, functioning as an insulation layer sandwiched between two cores or between a core and copper foil in a Printed Circuit Board (PCB).

Image Credit: Galaxy Scientific Inc

Due to the high costs of raw materials and the need to produce a high-quality final product, fast and accurate analytical methods must be implemented throughout all stages of the prepreg manufacturing process.

Conventional analytical techniques are often time-consuming and costly. They tend to be impractical for large-scale measurements, cannot typically deliver real-time feedback in manufacturing settings, and can usually only assess a single chemical or physical parameter per measurement. Near-Infrared (NIR) spectroscopy offers a potential alternative.

NIR spectroscopy is a rapid, non-invasive technique that can determine multiple parameters from a single measurement, requiring little to no sample preparation.

This method can be applied throughout all stages of the prepreg manufacturing process, from initial raw material analysis to real-time process control during manufacturing, and finally, as a quality control check on finished products.

NIR spectroscopy can improve operational efficiency and optimize the use of raw materials and resources. Due to its advanced analytical capability, NIR spectroscopy can stabilize product quality far beyond traditional analytical methods.

Galaxy Scientific FT-NIR spectrometers have been successfully used in prepreg manufacturing to monitor quality control parameters at every stage of the manufacturing process.

In particular, these spectrometers have been applied to analyze prepreg reinforcement materials used as insulation layers in printed circuit board (PCB) manufacturing. Their efficacy has been confirmed, establishing FT-NIR spectroscopy as a reliable and robust analytical method in this field.

Introduction to NIR Spectroscopy

NIR spectroscopy is used across multiple industries. This method relies on molecular overtones and combination vibrations within the electromagnetic spectrum, ranging from 12,500 cm-1 to 4000 cm-1.

NIR spectra reveal a unique fingerprint of tested samples, generated by the interaction of light with a sample as it passes through or reflects off the sample’s surface.

The resulting spectrum contains information related to the sample's chemical and physical properties. Although multivariate data analysis is required to correlate the NIR spectra with specific parameters of interest, calibration models offer significant advantages.

As mentioned, NIR spectroscopy offers a rapid, non-invasive analysis to traditional analytical techniques, requiring minimal to no sample preparation. It also avoids using hazardous chemicals and solvents, and enables the determination of multiple physical and chemical properties in a single measurement.

Fourier Transform NIR (FT-NIR) spectrometers use an interferogram signal converted into a spectrum of frequency against intensity.

FT-NIR spectrometers have several advantages over other NIR instruments. These include simultaneous wavelength measurements, enhanced resolution and signal-to-noise ratio, precise wavelength calibration, elimination of stray light, and excellent instrument reproducibility. This high level of consistency reduces the need for calibration model transfer between instruments.

NIR spectra provide information from the combination and overtone bands of C-H, N-H, and O-H vibrations. Since nearly all organic compounds contain these functional groups, NIR spectroscopy is particularly well-suited for analyzing key manufacturing parameters.

FT-NIR spectroscopy can be used for a wide range of research applications, including quality control, specification testing, and process control. It can also be used in laboratory and industrial settings, both online and offline.

Prepreg Manufacturing

Various techniques are used to manufacture prepregs, all of which use heat and pressure to process materials. Among the most common are solution dip, solution spray, hot melt, solvent dip, and vacuum treatment, with the hot melt and solvent dip methods most widely adopted across the industry.

In the hot melt process, production unfolds in two stages. First, a thin film of heated resin is applied to a paper substrate. Then, as the prepreg machine operates, pressure and heat are used to impregnate the resin into the fiber. The finished prepreg is subsequently wound onto a core, ready for storage or further processing.

The solvent dip method exclusively produces fabric prepregs. Here, the resin is dissolved in a solvent bath, and the reinforcing fabric is immersed in the solution. Once saturated, the fabric passes through a drying oven, where the solvent is evaporated, leaving behind a resin-coated fabric ready for curing.

Prepregs play a key role in PCBs, acting as the binding material between layers. During processing, excess resin is removed from the reinforcement, and the remaining resin enters what is known as the B-stage, where it partially cures, changing from a liquid to a pliable solid. This intermediate stage requires refrigeration to maintain stability before final use.

The curing process is driven by applying heat, activating the resin, and bonding it to the carrier material, forming a durable insulating layer. This step's temperature and pressure conditions directly influence the resin’s final characteristics.

Manufacturers monitor several key parameters in the finished prepreg to ensure consistent quality. These include resin content, gel time, resin flow, and volatile content, each an indicator of performance and reliability in demanding applications.

The following AZO Materials article provides a comprehensive overview of prepregs.

Composite Prepregs – Manufacturing, Benefits and Applications

Prepreg Quality Control and FT-NIR Spectroscopy

Table 1. Prepreg Quality Control Materials and Parameters. Source: Galaxy Scientific Inc

| Point In Process |

Material |

Analytical Method |

Parameter of Interest |

| Raw material |

Fibers |

Sampling With Wet Chemistry or Physical Measurement Analysis |

Width, Thickness, Base Weight, Warp and Weft Density |

| Resins |

Resin Content Percent, Gel Time, Viscosity |

| Chemicals |

Determination of Main Content and Conformity |

| Semi-finished product |

Pre-mix Starting Materials |

Gel Time, Specific Gravity |

| Baking Sheet |

Resin Content Percent, Gel Time, Resin Flow Percent, Volatile Content, Impurities Concentration, Bending Weft |

| Final product |

Prepreg |

Resin Content Percent, Gel Time, Resin Flow Percent, Volatile Content |

Table 1 summarizes the essential materials and parameters involved in the prepreg manufacturing process. Gel time measurements require a heating apparatus and an analytical scale.

Determining the percentage of resin content in a prepreg can be similarly complicated. It requires a furnace capable of reaching 550 °C and a desiccator to maintain low relative humidity. Assessing resin flow and volatile content in prepregs is also challenging.

Using these tests to conduct effective quality control measurements is particularly difficult, as they are not suitable for real-time, online analysis. Traditional analytical methods for prepreg evaluation come with significant limitations, which are further complicated by sample variability and the difficulties of extracting samples directly from the manufacturing floor.

Raw materials are often non-homogeneous, and testing a single sample is rarely enough to adequately represent this variability. Semi-finished products can also change due to solvent evaporation, making prior test results inaccurate. The harsh conditions of manufacturing environments complicate the sampling process.

Another key drawback of traditional methods is their inability to measure multiple parameters at once. This forces operators to collect several samples, even as product properties may shift in real time.

Overall, the challenges of traditional methods, such as time, cost, and sampling, make them impractical for large-scale testing or online process control. Their one-parameter-at-a-time approach does not meet the needs of modern production environments.

FT-NIR spectroscopy offers clear advantages, including assessing multiple quality control parameters with a single, fast measurement.

Materials, Parameters of Interest, and Current Research

Raw material testing for prepreg manufacturing includes resin content, organic chemicals, and adhesives. Resin is evaluated for content percentage, gel time, and viscosity.

The identification and conformity of primary components are key for organic chemicals. Adhesives are assessed for gel time and specific gravity.

Semi-finished products are tested for resin content percentage, gel time, resin flow percentage, volatile content, and impurities. FT-NIR spectroscopy has significant advantages as a process control tool.

Real-time feedback on active ingredients during manufacturing enables operators to make adjustments that yield more stable and consistent products.

The final prepreg product undergoes testing for resin content percentage, gel time, resin flow percentage, and volatile content. FT-NIR enables rapid sampling and a more representative analysis of the final products. Each batch can be promptly and accurately evaluated to ensure compliance with specifications.

Research into the spectroscopic analysis of prepreg materials is ongoing. A recent study assessed the feasibility of determining the glass transition temperature (Tg) in aged epoxy prepreg.

Tg is defined as the temperature at which a material transitions from a rigid, glassy state to a more flexible, rubbery state. This temperature can vary based on several factors, including the material grade, curing process, and moisture content.

Tg directly relates to the mechanical properties of a polymer, such as tensile strength, impact resistance, and elastic modulus. When prepregs are produced, they are partially cured and stored at low temperatures (typically around -18 °C) in the “B-stage”. This prevents the material from curing before the final step.

Prepregs are thawed from the B-stage before being processed into their final state. They must then be used within a limited processing window known as “out-time.”

Tg reveals a material's characteristics and can also be used to determine the shelf life and out-time of prepreg. As with other properties, NIR spectroscopy can be used to measure Tg, replacing traditional methods.

Another study investigated the determination of initiator content during the copper-clad laminate (CCL) production process. Initiator content can directly influence the cross-linking and curing degrees of resin, significantly impacting prepregs' final quality and properties.

Further studies have extended NIR applications to evaluate standard prepreg metrics in emerging materials. For instance, NIR has been used to determine resin and volatile content in PPBESK, a high-performance thermoplastic resin with a higher Tg than similar products.

Galaxy Scientific Prepreg Application

Figure 1. Galaxy Scientific QuasIR™ 3000. Image Credit: Galaxy Scientific Inc

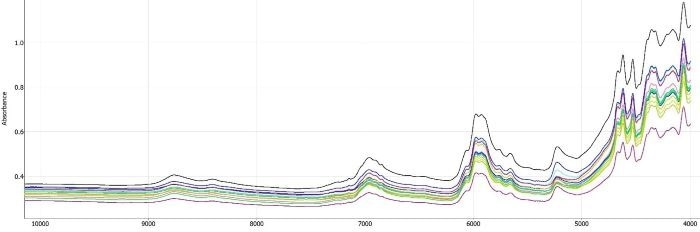

A Galaxy Scientific QuasIR™ 3000 FT-NIR spectrometer was used to evaluate the feasibility of determining key parameters in prepreg. Absorbance spectra of prepreg samples were collected from 10,000 cm-1 to 4000 cm-1.

Standard reference tests were conducted for the following parameters: Rubber/Resin Content percentage, Gel Time, and Glue/Resin Flow. Before chemometric modeling, various pre-processing algorithms were applied to the spectral data. Pre-processing enhances spectral features, such as peak definition and baseline correction.

Partial Least Squares (PLS) calibration models correlating the NIR spectra with each of the parameters of interest were developed.

Figure 2. FT-NIR Absorbance Spectra of Prepreg. Image Credit: Galaxy Scientific Inc

The PLS model statistics exhibited excellent results, demonstrating good agreement between the reference values and predictions derived from the NIR spectra.

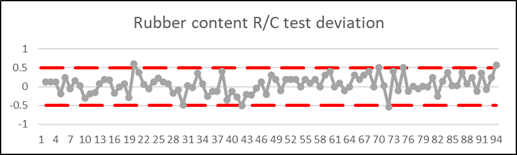

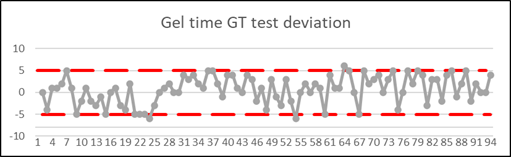

To assess the models, independent validation was performed. NIR spectra were collected from independent prepreg samples, and standard reference tests were conducted.

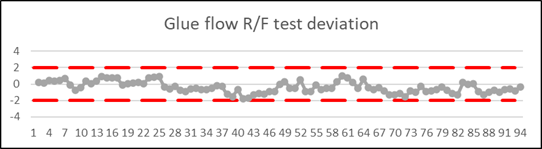

The deviation between the standard reference tests and predictions from the NIR spectra and PLS models is illustrated below.

Figure 3. Rubber/Resin Content Percent Reference vs. FT-NIR Method. Image Credit: Galaxy Scientific Inc

Figure 4. Gel Time Reference vs. FT-NIR Method. Image Credit: Galaxy Scientific Inc

Figure 5. Glue/Resin Flow Test Reference vs. FT-NIR Method. Image Credit: Galaxy Scientific Inc

As shown in the figures above, the FT-NIR and the reference methods produce highly consistent results across all three parameters of interest.

Galaxy Scientific

Galaxy Scientific is an industry leader in applying optical Near Infrared Spectroscopy. Our QuasIR™ family of NIR spectrometers utilizes Fourier Transform Near-Infrared (FT-NIR) technology for laboratory, field, and process applications.

Galaxy Scientific’s commitment to innovation drives its mission to develop uniquely robust NIR instruments that address critical analytical challenges across various sectors, including prepreg manufacturing.

This information has been sourced, reviewed and adapted from materials provided by Galaxy Scientific Inc.

For more information on this source, please visit Galaxy Scientific Inc.