Luis Roca, Lead Researcher in Compounding at AIMPLAS

Introduction

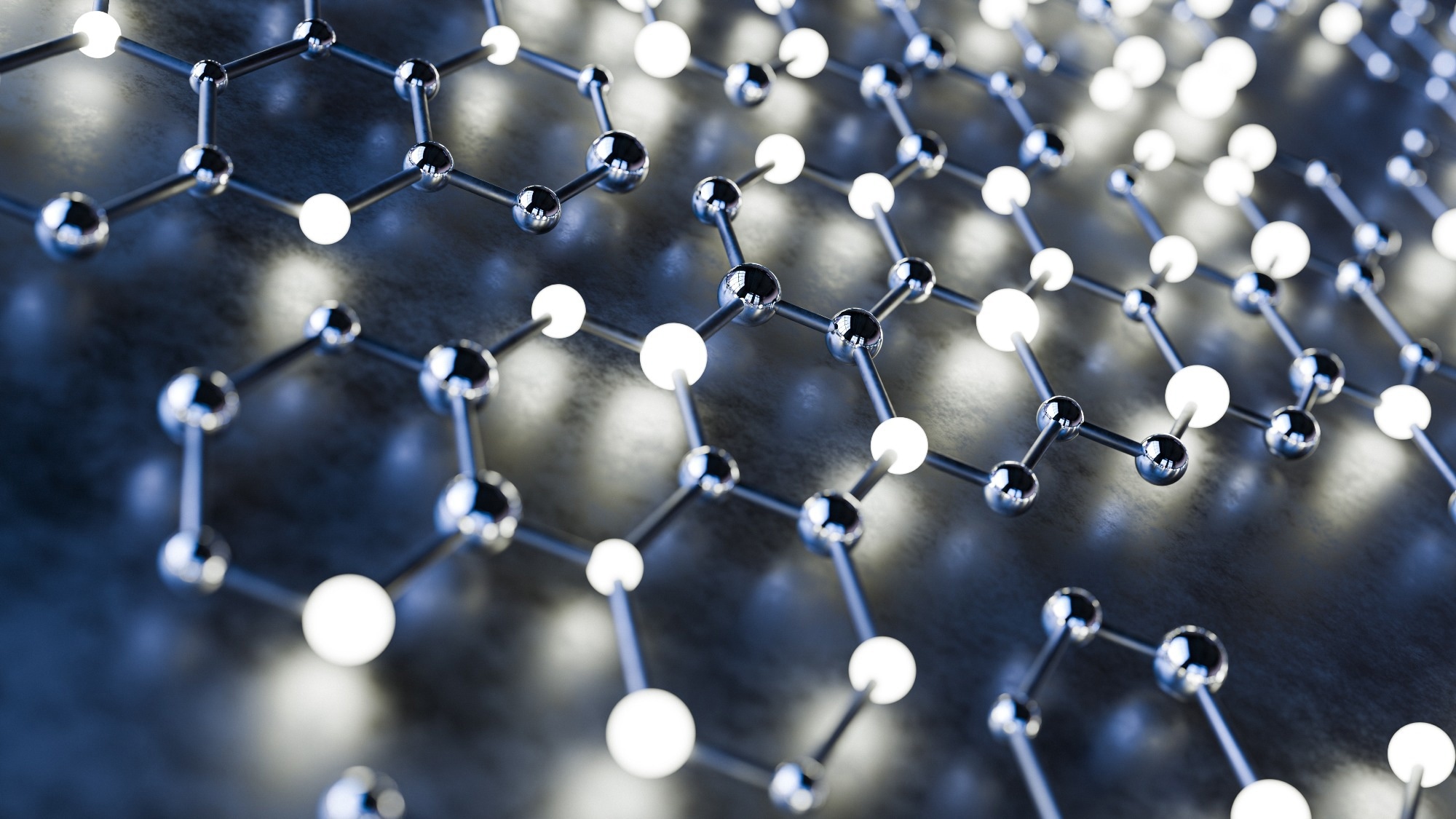

Graphene continues to maintain the interest of researchers, engineers, and industry because of its extraordinary qualities. The single atomic layer of carbon atoms has a two-dimensional honeycomb lattice, which lends it its unprecedented strength, high electrical and thermal conductivity, and flexibility.

Since its discovery over 20 years ago, graphene has been expected to change industries as diverse as electronics, energy storage, composites, coatings, and medicinal devices. However, the transition from laboratory to commercial-scale application has been slower than expected.

This article provides a thorough review of graphene's historical development, types, competing additions, problems, market trends, and prospects. It emphasizes the important issues of graphene's compounding and formulation use.

Image Credit: Cleiton_Ilustra/Shutterstock.com

Historical Timeline of Graphene

Graphene's journey from discovery to industrial use has been marked by impressive progress. It was first discovered in 2004, when Andre Geim and Konstantin Novoselov isolated graphene by mechanical exfoliation (Scotch tape), earning them the Nobel Prize in Physics in 2010.

From 2005 to 2010, there was increased academic interest in theoretical studies and basic applications of the new ‘wonder material’.

Between 2010 and 2015, industrial interest began to grow. CVD and liquid-phase exfoliation technologies improved, and companies began investigating graphene in conductive inks, coatings, and composites. Cost and scale were the limiting issues in graphene's progress. Expectations for the material grew, with many believing that graphene would soon disrupt a variety of industries.

In 2015-2020: As technological and economic constraints persisted, initial enthusiasm faded, and expectations became more realistic. The emphasis switched to scalable technologies, such as electrochemical exfoliation, and practical applications in which graphene's unique features justified its cost. Early commercialization applications included sports equipment, automotive parts, and flexible electronics.

From 2020 to the present, innovations like flash graphene (Rice University) have reduced costs and environmental impact. Bulk nanoplatelet prices have fallen below $20/kg, although high-quality monolayer graphene is still expensive. Market acceptance of the material is steadily increasing, propelled by attainable, application-specific improvements rather than broad technology upheaval.

Types of Graphene and their Properties

One of the biggest challenges with graphene is the variety of types, a lack of standards, nomenclature, and so on. This limited its applicability when it was first developed because of the large amount of confusion it created.

Currently, we can find the following graphene structures that could be related more specifically to final applications:

- Monolayer Graphene: A single layer of carbon atoms, this material has excellent electrical, thermal, and mechanical qualities. It is best for electronics, sensors, and photonics, but it is expensive and difficult to create at scale.

- Graphene Oxide (GO): Graphene sheets with functional oxygen groups. GO is dispersible in water and ideal for membranes and coatings, but has low electrical conductivity.

- Reduced Graphene Oxide (rGO): Partially restored graphene structure obtained after reducing GO. Improved conductivity over GO; utilized for batteries, supercapacitors, and composites.

- Graphene Nanoplatelets (GNPs): Multi-layered stacks (generally three to ten layers) that are cost-effective reinforcing materials for plastics, rubbers, and coatings.

- Few-Layer Graphene (FLG): Two to five layers thick. FLG has good electrical characteristics and is easier to manufacture than monolayer graphene.

Potential clients should be aware of these characteristics to better define their needs and match them with the graphene type required for optimal performance.

Examples of Graphene Applications in Plastics

Graphene is slowly permeating numerous added-value markets. Some examples of contemporary graphene applications are as follows:

- Automotive components: Graphene nanoplatelets improve strength, impact resistance, and thermal stability in polypropylene (PP) and polyamide (PA) automotive components.

- Sports equipment: Graphene-filled TPU is used in sports equipment, including bicycle frames, rackets, and helmets, to increase durability without adding weight.

- Conductive plastics: Conductive plastics, like graphene-infused PC and ABS, can provide antistatic and EMI shielding properties.

- 3D printing filaments: Graphene-infused PLA or ABS filaments enhance the strength and conductivity of 3D prints.

- Packaging: Packaging options include polyethylene films with graphene for enhanced barrier qualities.

- Masterbatch concentrates: Masterbatch concentrates include graphene for easy handling and dispersion.

Graphene’s Competitors

Graphene faces a challenge in competing with well-established fillers in the plastic industry, such as carbon black, graphite, and CNTs. Graphene can compete here, but it must be chosen appropriately.

- Carbon black is a traditional material used for conductivity and reinforcement.

- Carbon nanotubes (CNTs) have similar potential in materials and electronics.

- Graphite provides electrical conductivity, whereas Boron Nitride is used for thermal management.

- These materials commonly require reinforcing additives such as silica and talc, whereas graphene offers multifunctionality.

- Graphene is a lighter and more corrosion-resistant alternative to metal fillers.

The main providers have created masterbatches to ease the introduction of graphene into plastics by avoiding powder handling, facilitating dispersion, and optimizing final performance.

However, if dispersion can be increased, there is room for improvement. From this perspective, more research should be done on increasing dispersion and how final processing affects final attributes.

Graphene has various advantages over other carbon-based materials (including carbon black, graphite, and carbon nanotubes). The choice is dependent on the intended application, although graphene's multifunctionality is a crucial distinction.

Current Challenges for Graphene

Several technical and market constraints continue to impede graphene's widespread implementation. This includes cost and scale, as producing high-quality monolayer graphene is expensive.

Other challenges are the technical complexity of producing uniform dispersion in matrices, a lack of global standards leading to variable quality across graphene products, and industries needing education to implement graphene.

Future Perspectives

Graphene's future is shaped by targeted developments that match its unique features to specific industrial needs, all of which are tied to broader industry megatrends. Promising areas could include:

- Energy storage options include supercapacitors and batteries with increased capacity.

- Automotive, aerospace, and sports industries are adopting advanced composites.

- Flexible electronics and sophisticated sensors, including wearables.

- Sustainable Manufacturing: Waste-to-Graphene methods.

Conclusion

Graphene's story is evolving from scientific curiosity to a practical material. Ongoing developments point to increased adoption in the coming decade. Its versatile characteristics ensure that it remains a focal point for innovation, albeit guided by more realistic expectations in recent years.

Expert guidance on compounding, processing, and formulation strategies can help companies convert graphene's potential into real value.

This information has been sourced, reviewed, and adapted from materials provided by AIMPLAS.

For more information on this source, please visit AIMPLAS.