Gary Bailey, Quality Analyst at American Crystal Sugar

For industrial sugar manufacturers, the capacity to detect the purity of their product is vital for their success. Gary Bailey of American Crystal Sugar discusses how visible and UV-visible spectrophotometry offer the data required to assure that his company's goods meet the standards.

Image Credit: New Africa/Shutterstock.com

Introduction

The US Department of Agriculture estimates that sugar beets account for over half of domestic sugar production.

Sugar beets, produced all over the northern Great Plains, must be treated to extract and purify the sucrose inside them. Producers such as the American Crystal Sugar Company carry out this task industrially.

Refined sugar ranges in color from dark brown to dazzling white, although the transition is often too subtle and gradual for the naked eye to detect. These color differences must be discovered and addressed during the refinement process. Color testing is most commonly done with a spectrophotometer.

Spectrophotometers provide immediate feedback, allowing for real-time refining adjustments. These changes could save a lot of time and money for a sugar-producing facility.

Challenges

American Crystal Sugar Company, an agricultural cooperative, is one of the major sugar beet producers in the US. The company is situated in the Red River Valley of Minnesota and North Dakota, where scores of farmers harvest vegetables for five distinct processing units.

The natural variability of crops poses continual hurdles for a corporation aiming to produce a consistent, high-quality product.

Gary Bailey, Quality Analyst for American Crystal Sugar, monitors the refinement process and ensures that the end sugar product meets all necessary criteria, regardless of differences in the starting material.

Quality control begins shortly after the source beets enter the processing plant and continues throughout the extraction and refinement processes. Sugar extraction starts with the beets being cut and steeped in water. The sucrose dissolves from the vegetable materials and into the water, resulting in a solution known as "raw juice."

Aside from the desired sugar, raw juice contains a slew of undesirable ingredients. Raw juice samples must be analyzed to establish the optimal approach for moving forward. A UV-visible spectrophotometer is the best tool for this purpose.

The starting juice is filtered in multiple phases, with undesired materials (dirt, beet pulp, etc.) removed before the excess water is evaporated in stages. Depending on their consistency and hue, the progressively pure and concentrated solutions are known as thin juice, thick juice, or high green juice.

Each juice is evaluated for purity and color value at every step. Near the end of the process, the concentrated solution is cooked in a large pan to crystallize the sugar. At this time, a large proportion of the “mother liquor” remains in sugar.

The solution is transferred to a centrifuge, where the denser sugar particles are driven to the bottom of the mixture while the liquid and its dissolved impurities are drained away to form molasses. The materials recovered by the centrifuge are 99 percent pure crystal sugar. The newly crystallized sugar and molasses are separately evaluated.

“We do a color test on the production line every hour,” Bailey reported. “So that is at least 24 times a day.”

Sugar is tested several times daily along the entire production chain. Every batch of processed sugar is tested before it is deposited in a silo and stored.

Each time sugar is extracted from the silo, it is tested again. Every rail car of sugar that leaves a processing plant is inspected for color. Bagged items are also often evaluated. Processing factories operate 24 hours a day, seven days a week; sending samples to a lab for testing would be extremely impracticable.

A strong, dependable analytical instrument is required in such a rigorous setting. Any equipment must also be user-friendly for on-site workers and produce results quickly.

Another necessity is instrument standardization; many devices of the same kind are utilized across multiple factories, all with the goal of producing a uniform product. Regardless of the analytical instrument employed, the organization must be confident in the consistency of test techniques and results.

Methods and Motivation

Sugar companies around the world adhere to protocols established by ICUMSA, the International Commission for Uniform Methods. The ICUMSA standards set color values for sugar in international units (IU).

Typical white sugar has a value of 30-35 IU; a highly pure, low-color sugar has a value of 15-20 IU; and darker 'raw' sugars can have a value of 600 or even 1000 IU. The test methodology most commonly used at American Crystal Sugar is known as ICUMSA-420.

The '420' refers to the precise wavelength of light employed during the analysis, which is 420 nm. Several more ICUMSA procedures exist, each designed to meet a unique requirement, such as analyzing colorful syrups or determining the turbidity of sugar solutions.

The most common test used by sugar companies, such as American Crystal Sugar, is ICUMSA-420. Producers assign a color value to each batch of sugar. That value is calculated by the amount of light absorbed by test samples when they are placed in a spectrophotometer.

An aqueous solution of pure sugar does not absorb 420 nm light, however substantial impurities like molasses do. Lower absorbance results in lower IU values, which indicate purer sugar.

During processing, analysts must know in real time if the conditions for the current batch of sugar need to be adjusted.

'Adjustment' can refer to adding more water to the batch, boosting carbonation levels, or extending the spin time in the centrifuge. In rare cases, an upset in the sugar process may cause a significant increase in color value, rendering the product unsellable.

Being able to assess color value early in the refining process helps prevent costly setbacks, such as the need to remelt and recrystallize an entire batch. Remelting sugar is a time-consuming process that can take several hours and result in significant production costs.

Customers care about the color of a batch of sugar. “Different customers will ask for different colors,” Bailey explained. One soft drink company “does a throwback [formula] where they use sugar instead of corn syrup.”

The company is extremely particular about the hue of its finished product. They need it to be a specific and commonly known shade of yellow.

Bailey explained that this is because the sugar cannot darken the final product, “so they ask for a lower color sugar than other people would.”

Other clients, such as chocolate producers, are less worried about whether the sugar they purchase is darker because their other additives (e.g., cocoa powder) will disguise the sugar hue.

Bailey pointed out, “If we were to send a sugar that did not fit their specs properly… that could be a big complaint for us from a customer.” Therefore, the primary concern is that the reported color value is accurate.

A Solution

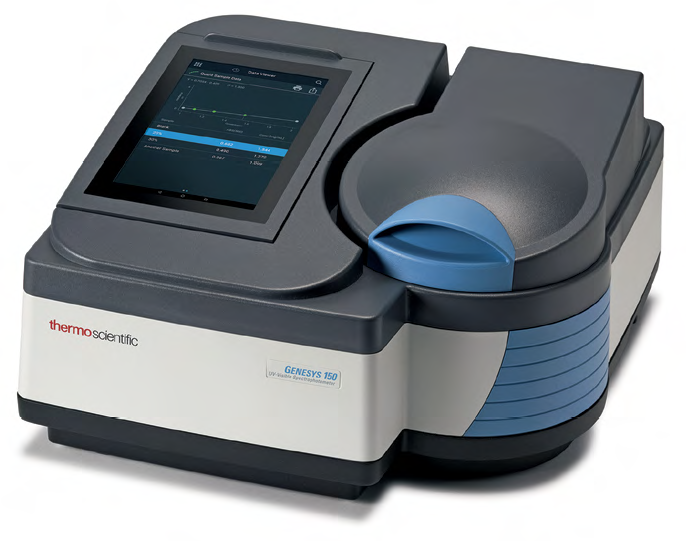

American Crystal Sugar Company found Thermo Scientific™ GENESYS™ visible and UV-vis spectrophotometers best suited their needs. The instruments are small and strong enough that many of them could be purchased and placed in various spots along the production lines across each plant.

Because the GENESYS UV-Vis Spectrophotometers can scan the whole ultraviolet-visible spectrum, they can be utilized for additional quality assurance tests as needed. This adaptability is just one further reason why sugar production companies choose to employ a spectrophotometer over a more limited device such as a colorimeter.

Advantages and Applications

American Crystal Sugar's five sugar processing plants all use GENESYS Visible and UV-Vis Spectrophotometers. The instruments show consistent accuracy throughout a wide range of concentrations, providing reliable readings regardless of whether a sample's color value is high or low.

This dependability is important because the ICUMSA tests require quantitative numbers, and customers also demand quantifiable values. The GENESYS 140 Visible Spectrophotometer's ease of use gives a huge corporation like American Crystal Sugar an additional advantage.

It is a "plug-and-play" instrument. The user inserts a water blank for calibration before removing the blank and inserting the sample. From this point forward in the analysis, the spectrophotometer almost runs itself. Training employees on how to utilize the gadget is simple.

Teaching personnel how to undertake correct sampling and testing methods takes longer than getting findings for those samples. The ability of the GENESYS 140 Spectrophotometer to be configured simplifies operation even further.

American Crystal's IT department created a custom program for the spectrophotometer that automatically registers the sample's absorbance, interprets the data, and returns a color value in IUs. Custom programming shortens the time between sampling and actionable test results.

The short turnaround time allows staff to fix any immediate production difficulties identified by the testing. Bailey is particularly impressed by GENESYS Spectrophotometers' capacity to produce reliable readings consistently from one instrument to the next.

To ensure that all chemists across their factories do consistent analyses, American Crystal Sugar has a monthly meeting to standardize their testing methods. All methods are the same throughout the organization, and equipment is identical across five factories.

The chemists will conduct company-wide assays on a known batch of sugar, with each analyst completing the identical tests on a different spectrophotometer.

The assurance of consistency that comes from having different people test the same known batch of sugar across multiple instruments at all five locations and then delivering statistically similar results strengthens trust in the company's products, methods, people, and spectrophotometers.

“If there were a significant difference in the results, then we would have to look at that and say, is something going on with the machine? Is there something going on with the analyst?” Bailey said.

Any major variation in results must be analyzed to determine why the discrepancy occurred.

“Honestly,” Bailey admitted, “month to month as those [test results] come back, those numbers are all very close.”

This is how he knows that Thermo Fisher Scientific's spectrophotometers produce consistent findings, allowing American Crystal Sugar to have confidence in the sugar it distributes.

Conclusion

Subtle differences in sugar color can mean the difference between a satisfied or dissatisfied customer and a rejected batch, potentially requiring costly reprocessing.

At American Crystal Sugar, color monitoring is carried out is conducted using GENESYS 140 Visible and GENESYS 150 UV-Vis Spectrophotometers. These tools provide reliable, consistent results that the company depends on to maintain product quality.

A flawed analysis could lead to a color mismatch and force a product recall, which would be highly costly. However, the equipment has proven dependable, with no such incidents to date. As one of the largest sugar beet producers in the United States, American Crystal Sugar sees GENESYS spectrophotometers as a valuable part of its quality assurance process.

GENESYS 150 UV-Vis Spectrophotometer. Image Credit: Thermo Fisher Scientific – Production Process & Analytics

This information has been sourced, reviewed and adapted from materials provided by Thermo Fisher Scientific – Production Process & Analytics.

For more information on this source, please visit Thermo Fisher Scientific – Production Process & Analytics.